Constant-pressure valve capable of enabling partial pressure of water vapor to be constant

A water vapor partial pressure and constant pressure valve technology, applied in safety valve, balance valve, valve device and other directions, can solve the problems of inaccurate opening, large fluctuation of system humidity, fatigue damage of dehumidification unit, etc. The effect of slowing the penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

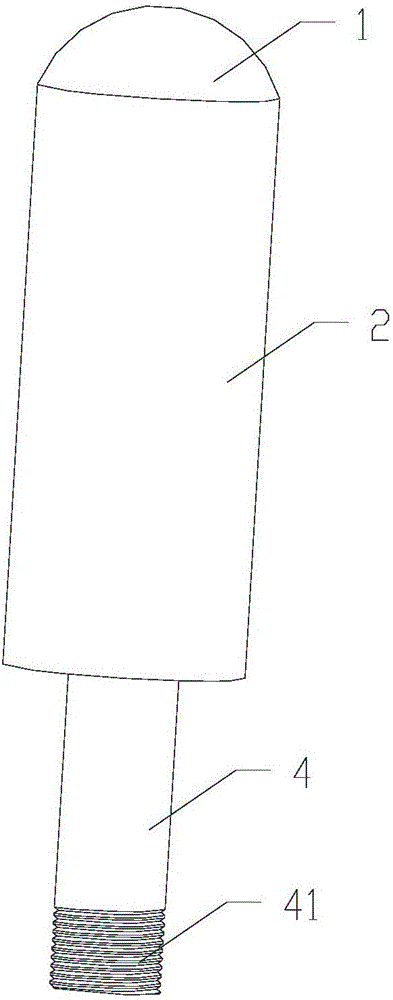

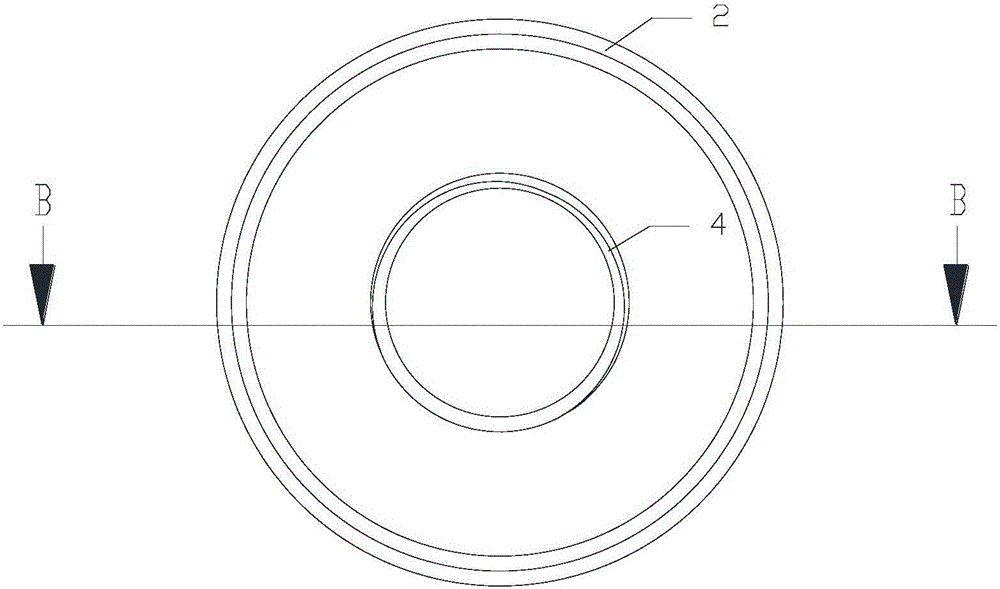

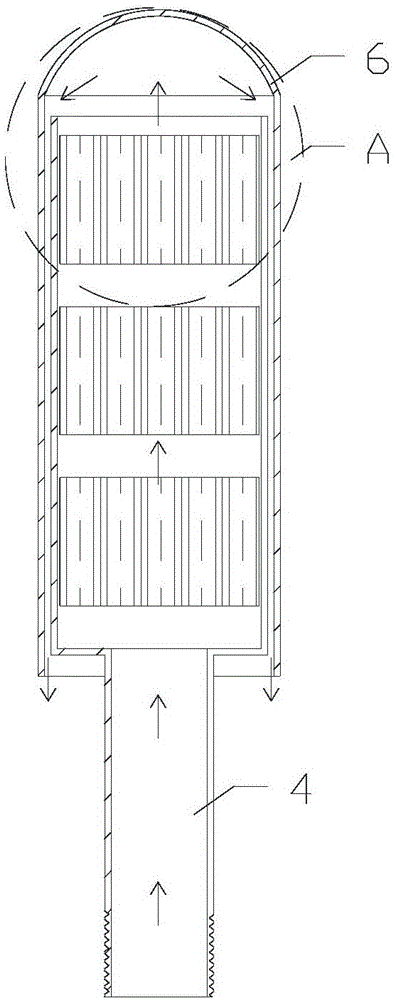

[0027] refer to Figure 1-2 , 4, a constant pressure valve with constant water vapor partial pressure, including a valve cover 1 and a valve body 2, the valve cover 1 is set on the valve body 2, and an exhaust passage 3 is left between the valve cover 1 and the valve body 2 . The shape of the silica gel inner core 5 is adapted to the shape of the inner wall of the valve body 2 , the valve body 2 is a cylinder, and the silica gel inner core 5 is a cylinder adapted to the shape of the inner wall of the valve body 2 . The length of the valve body 2 is 130-150 mm, and the width of the valve body 2 is 50-70 mm; the length of the valve body 2 in this embodiment is 135 mm, and the width is 57 mm.

[0028] One end of the valve cover 1 is a closed end, and the other end is an open end, and the valve body 2 extends into the valve cover 1 from the open end of the valve cover 1 . The open end of the valve cover discharges air along a 360° direction, which minimizes the exhaust being aff...

Embodiment 2

[0034] refer to image 3 , The closed end of the bonnet 1 is provided with an arc-shaped bonnet 6 for sheltering from wind and rain. The setting of the arc-shaped bonnet 6 can block the wind, rain and dust in all directions; when the wind blows, when the wind passes through the bonnet 1, the wind force is dispersed along the arc-shaped bonnet 6, which avoids the constant pressure valve being affected by the wind when it rains. Rainwater and dust fall on the arc-shaped bonnet 6 and slide down along the arc, preventing rainwater and dust from accumulating on the bonnet 1.

[0035] Other structures and connection methods are the same as in Embodiment 1.

experiment example

[0037] The present invention applies the constant pressure valve to Wuhan Gutian Bridge and Yingwuzhou Yangtze River Bridge. After more than one year of actual data monitoring, the following data are obtained:

[0038] Experiment 1

[0039] When the external water vapor partial pressure is 4KPa, the time for water vapor to penetrate into the main cable and cause the humidity to rise from 20%RH to 40%RH is shown in Table 1:

[0040] Table 1 Humidity schedule of water vapor penetration at 4KPa

[0041]

[0042] Experiment 2

[0043] When the external water vapor partial pressure is 2KPa, the time for water vapor to penetrate into the main cable and cause the humidity to rise from 20%RH to 40%RH is shown in Table 2:

[0044] Table 2 Humidity schedule of water vapor penetration at 2KPa

[0045]

[0046] It can be obtained from Table 1 and Table 2 that when the external water vapor partial pressure of the constant pressure valve of the present invention is 2KPa, water vapor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com