A Rotary Valve for Large Oxygen Concentrator

An oxygen generator and rotary valve technology, applied in the field of rotary valves, can solve the problems of inability to count the number of rotations of the rotary valve, inability to apply oxygen production equipment, inability to judge motor damage, etc., and to meet the requirements of gas circuit control, on-off precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

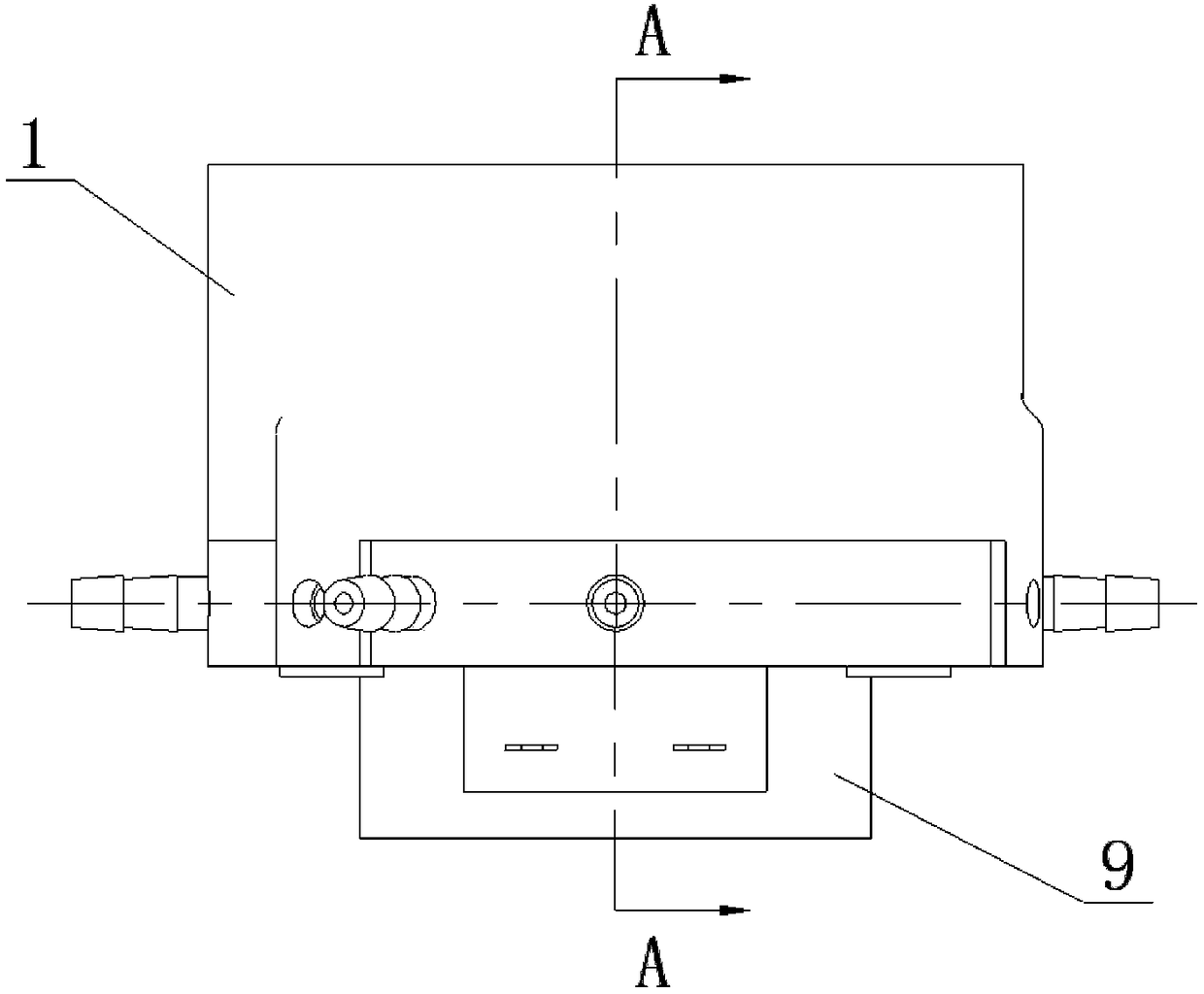

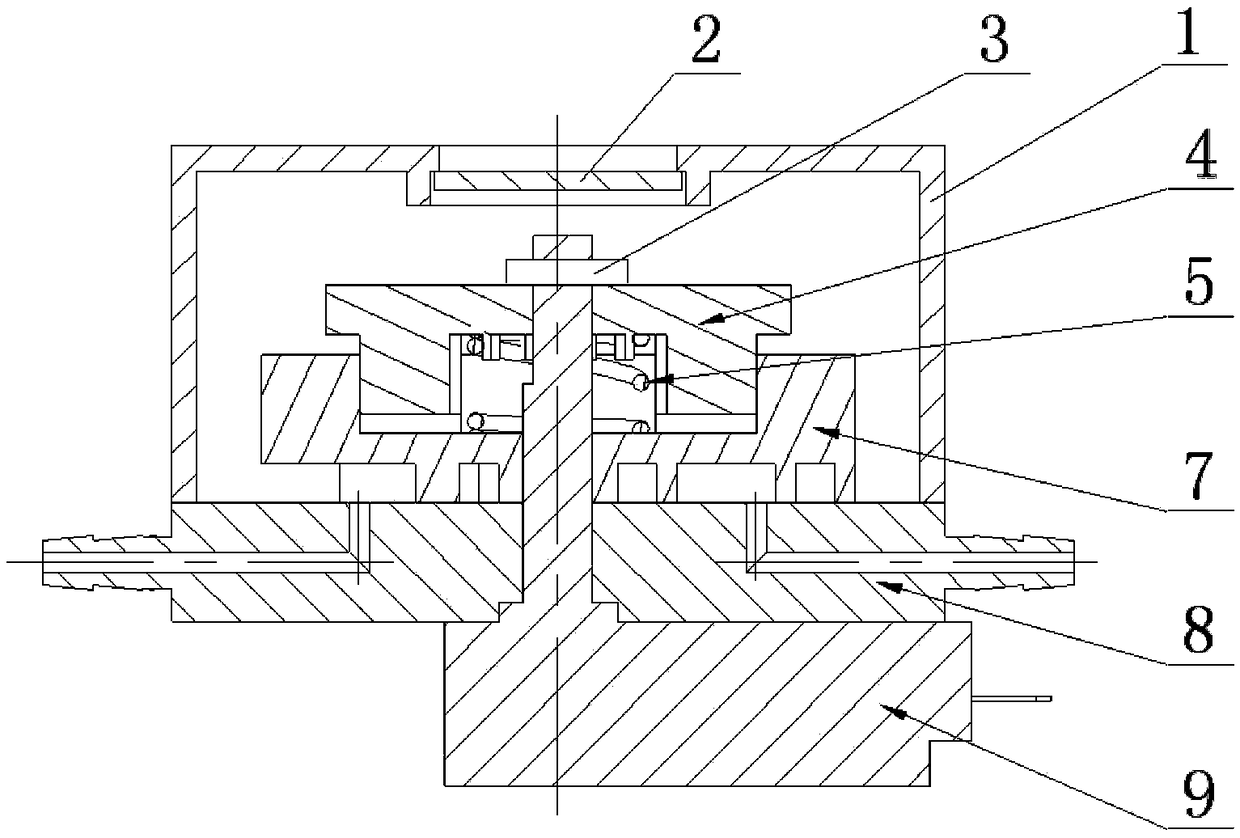

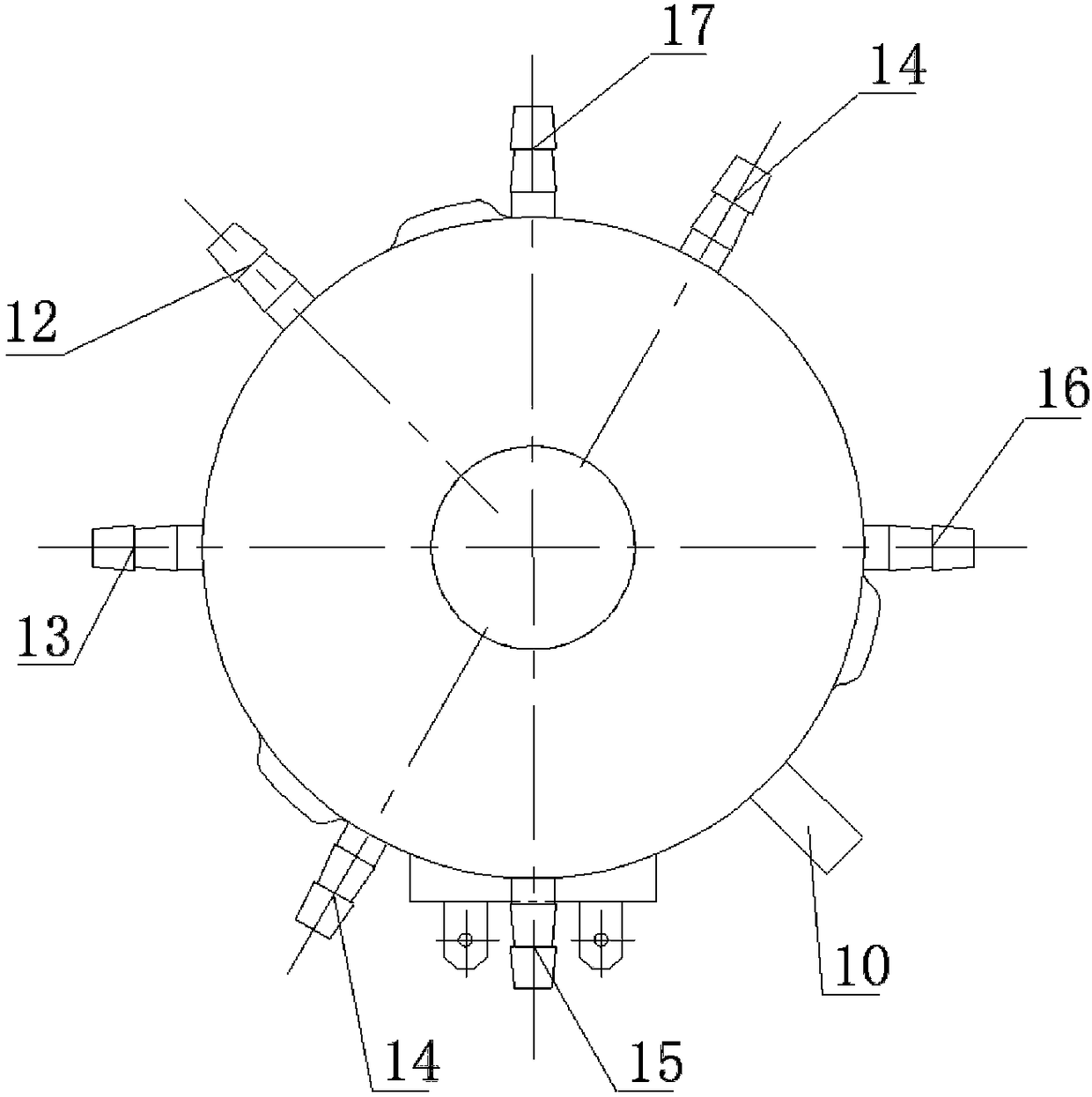

[0020] As shown in the attached figure, a rotary valve for a large oxygen generator includes a motor 9, a static piece 8, a moving piece 7, an outer spring 5, an inner spring 6, a transmission piece 4, a muffler cover 1, and a muffler piece 2 1. Proximity switch 10, the static plate 8, the moving plate 7, the outer spring 5, the inner spring 6, and the transmission plate 4 are successively set on the motor shaft of the motor 9 from bottom to top, and pass through the motor shaft through the pin shaft 3 , so that it is assembled as a whole, wherein, the inner spring 6 and the outer spring 5 make the moving piece 7 tightly pressed on the upper surface of the static piece 8 to form a seal, and the moving piece 7 is rotatably matched with the static piece 8, and the transmission The piece 4 cooperates with the moving piece 7 and can drive the moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com