Damping type corrugated pipe compensation moving ring component of mechanical sealing device and application

A technology of mechanical sealing device and bellows, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of reduced service life, fatigue fracture of welded metal bellows, etc., so as to improve service life, reduce fracture problems, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

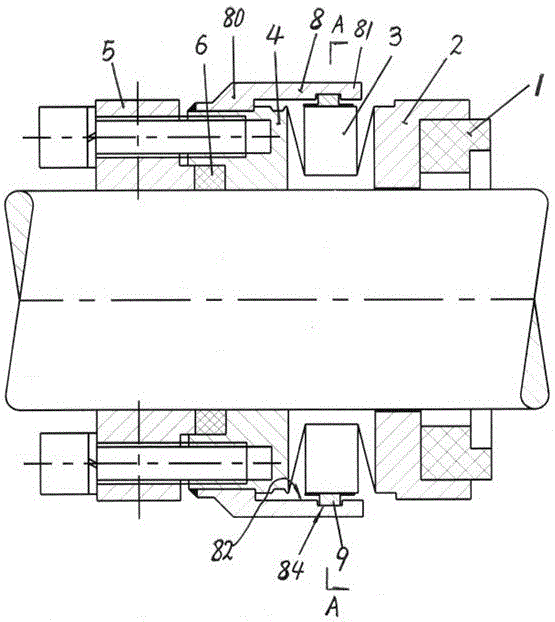

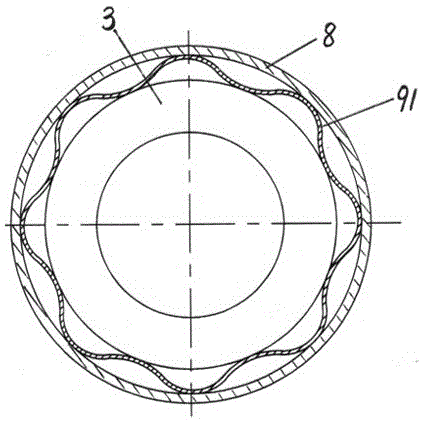

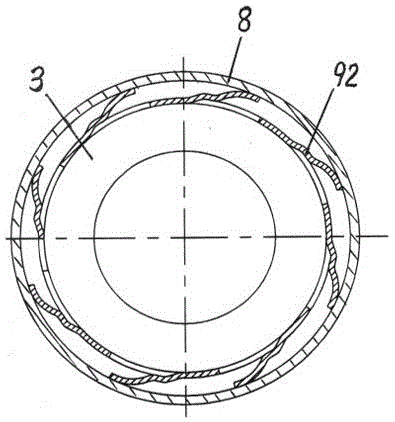

[0017] The damping bellows compensation dynamic ring assembly of the mechanical seal device of the present invention includes a dynamic friction ring 1, a dynamic friction ring seat 2, a welded metal bellows 3, a tailstock 4, a transmission seat 5, a sealing ring 6, and a welded metal bellows 3. The front and rear ends are respectively welded with the dynamic friction ring seat 2 and the tailstock 4, and it is characterized in that the tailstock 4 is fixedly connected with a ring sleeve 8, the rear end 80 of the ring sleeve 8 is fixedly connected with the tailstock 4, and the ring sleeve 8 The front end 81 is an open end, and the front end 81 of the ring sleeve 8 extends to the front of the welded metal bellows 3, and a groove 84 is opened on the inner ring surface 82 of the front end 81 of the ring sleeve 8, and is fixedly connected in the groove 84. A damper 9 is installed, and the inner surface of the damper 9 contacts and cooperates with the outer ring surface of the welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com