Spool outer ring spiral groove type 2d electro-hydraulic high-speed switch valve

A high-speed switching valve, spiral groove technology, applied in multi-way valve, valve device, valve details and other directions, can solve the problem of weak and strong spool machining precision spool and other problems, achieve high self-cleaning ability, increase control flow, increase Effect of Spool Diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

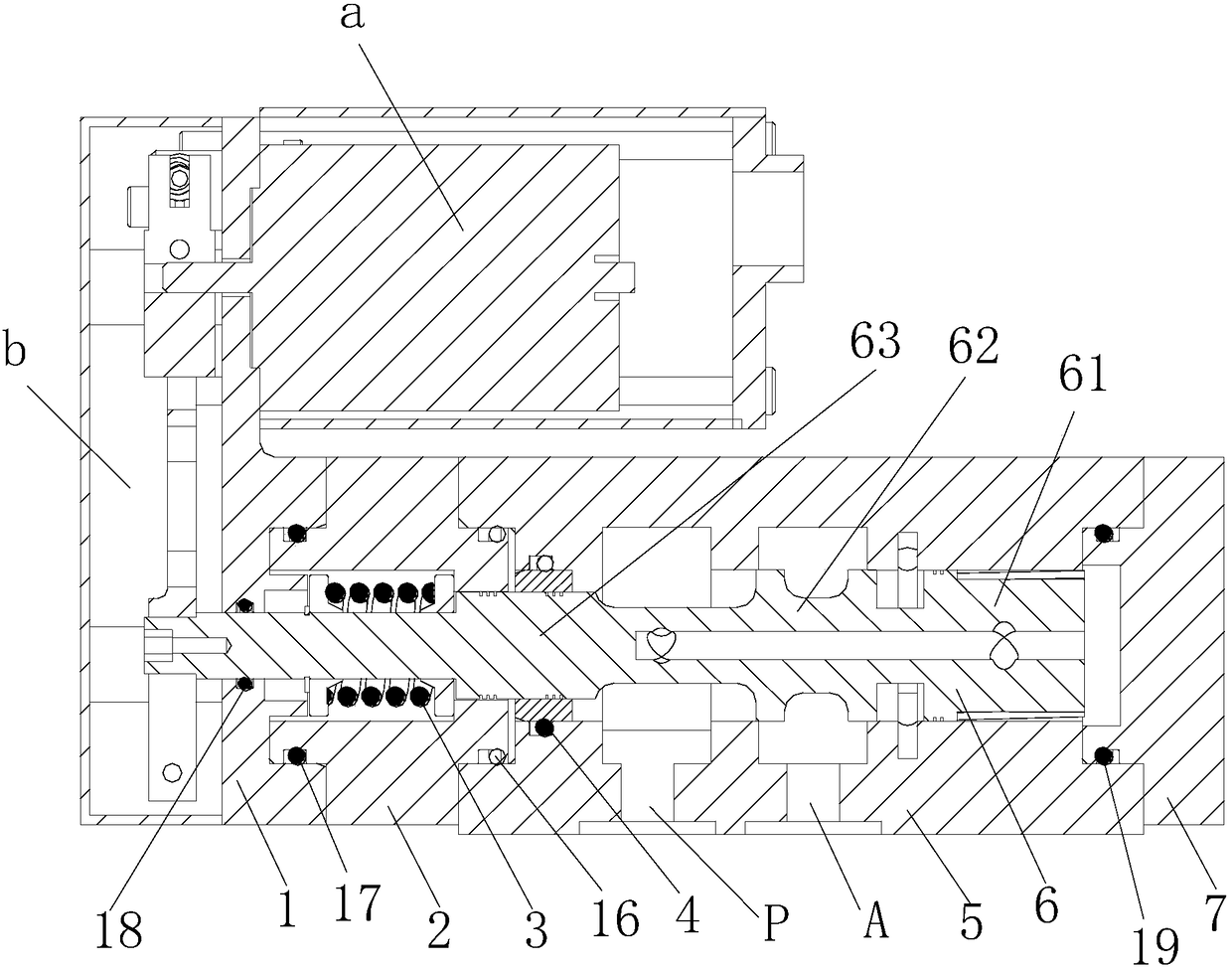

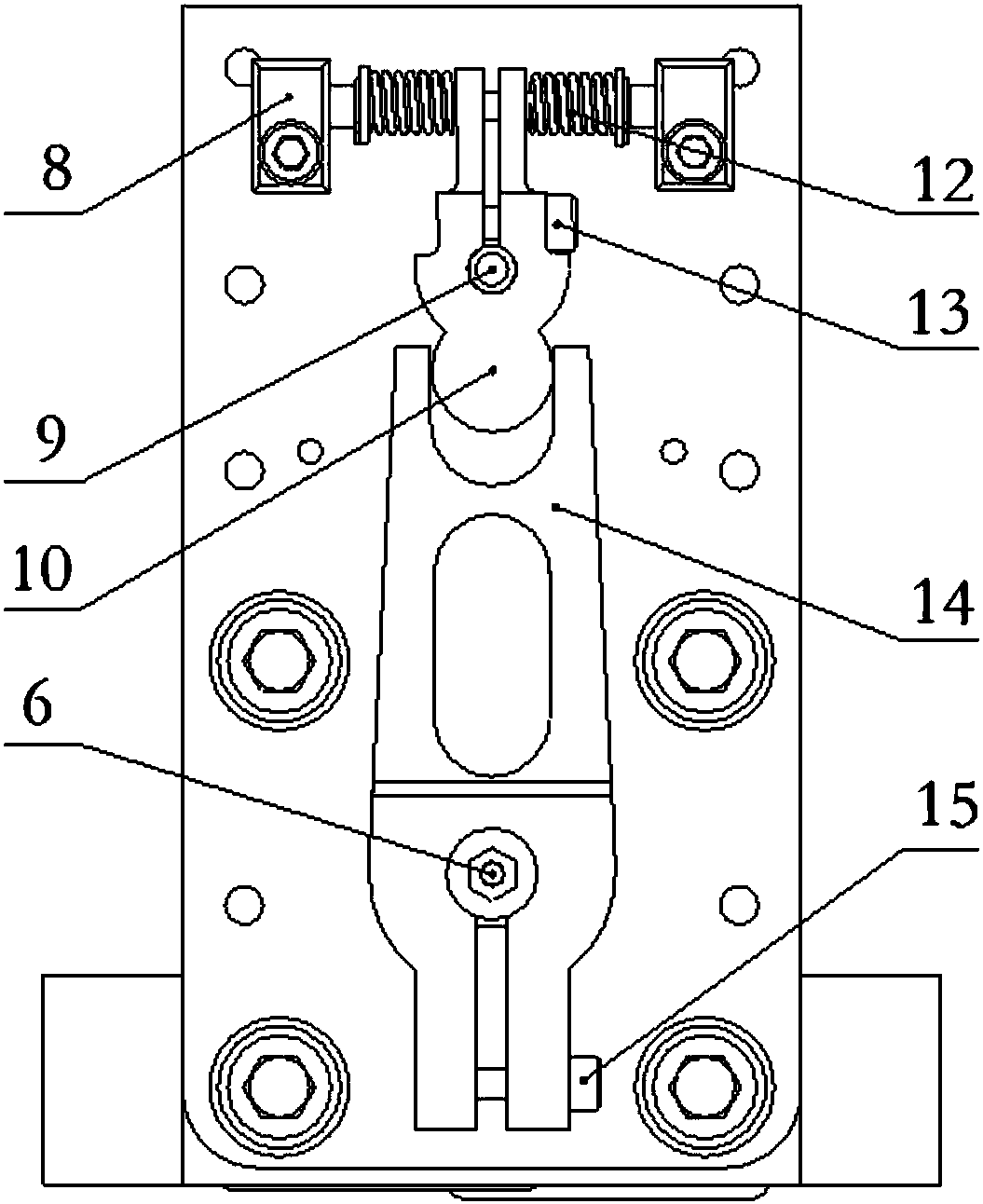

[0042] As shown in the figure, the spiral groove type 2D electro-hydraulic high-speed switch valve on the outer ring of the valve core includes the valve body, the transmission mechanism that drives the valve body to open or close, and the zero position holding mechanism that drives the valve body to reset;

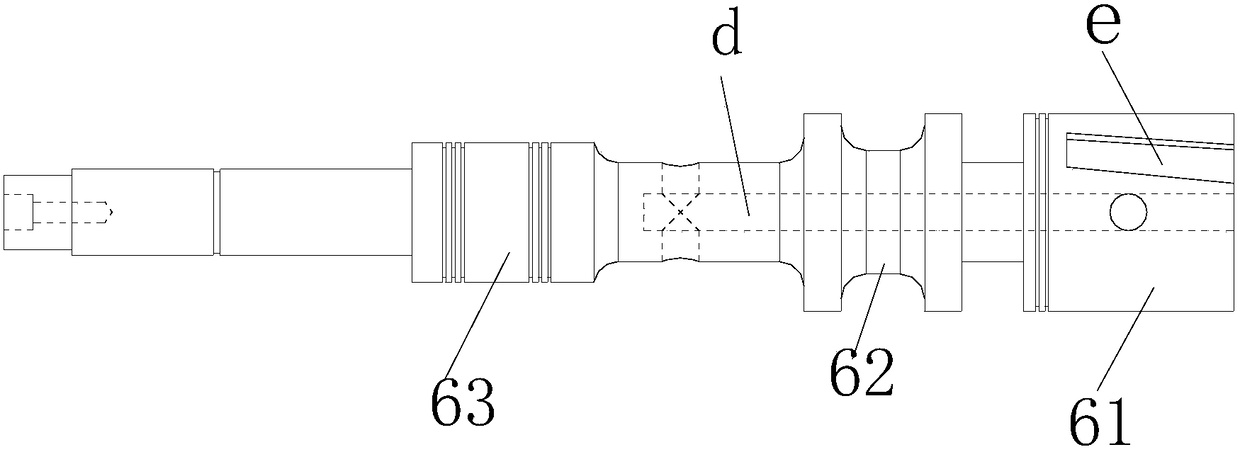

[0043] The valve body includes a servo screw mechanism composed of a valve body 5 and a valve core 6. The valve core 6 is rotatably arranged in the valve body 5. The valve core 6 is provided with a first shoulder 61 and a second shoulder in sequence from right to left. 62 and the third shoulder 63, the right end cover 7 and the first shoulder 61 of the valve body 5 airtightly enclose the inner cavity of the valve body 5 into a sensitive chamber i, and the first shoulder 61 and the second shoulder 62 seal the valve body 5. The inner cavity of the valve body 5 is airtightly enclosed to form an annular oil outlet cavity surrounding the spool 6, and the second shoulder 62 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com