Taper sleeve type mechanical locking oil cylinder

A mechanical locking and oil cylinder technology, applied in mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of poor sealing performance, axial displacement of piston rod, complicated operation, etc., and achieve reliable working performance, good sealing performance, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the specific embodiments of the present invention to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments, for those of ordinary skill in the art, as long as various changes These changes are obvious within the spirit and scope of the present invention defined and determined by the appended claims, and all inventions and creations that utilize the concept of the present invention are protected.

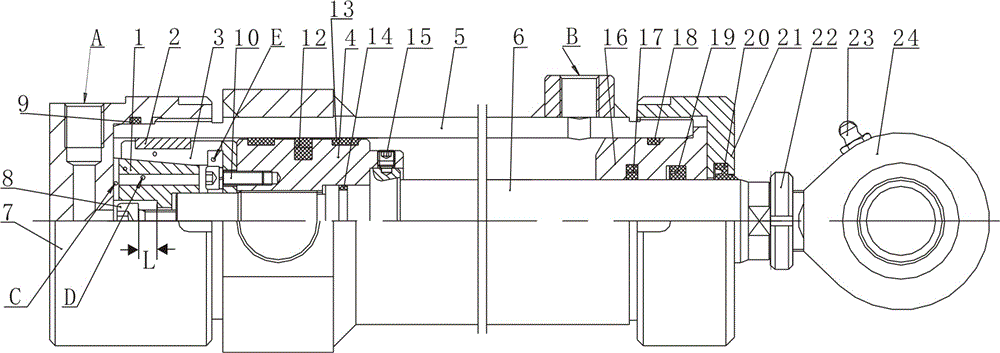

[0019] Such as figure 1 The shown cone sleeve type mechanical locking oil cylinder includes a cylinder barrel 5, a cylinder head 7, a second guide sleeve 16, a nut 21, a piston 4 and a piston rod 6, and also includes a cone top 1, a copper bearing bush 2 and a cone sleeve 3. . Among them, the piston 4 is sleeved on the outer edge of the piston rod 6, the rear part of the cylinder 5 penetrates the piston 4 and is firmly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com