Coil pipe fan structure

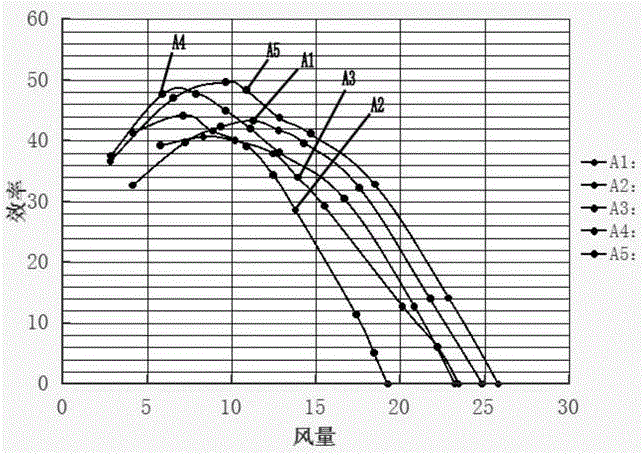

A coil fan and fan technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of noise generation, affecting fan efficiency, unreasonable parameter ratio design, etc., to reduce noise and improve operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

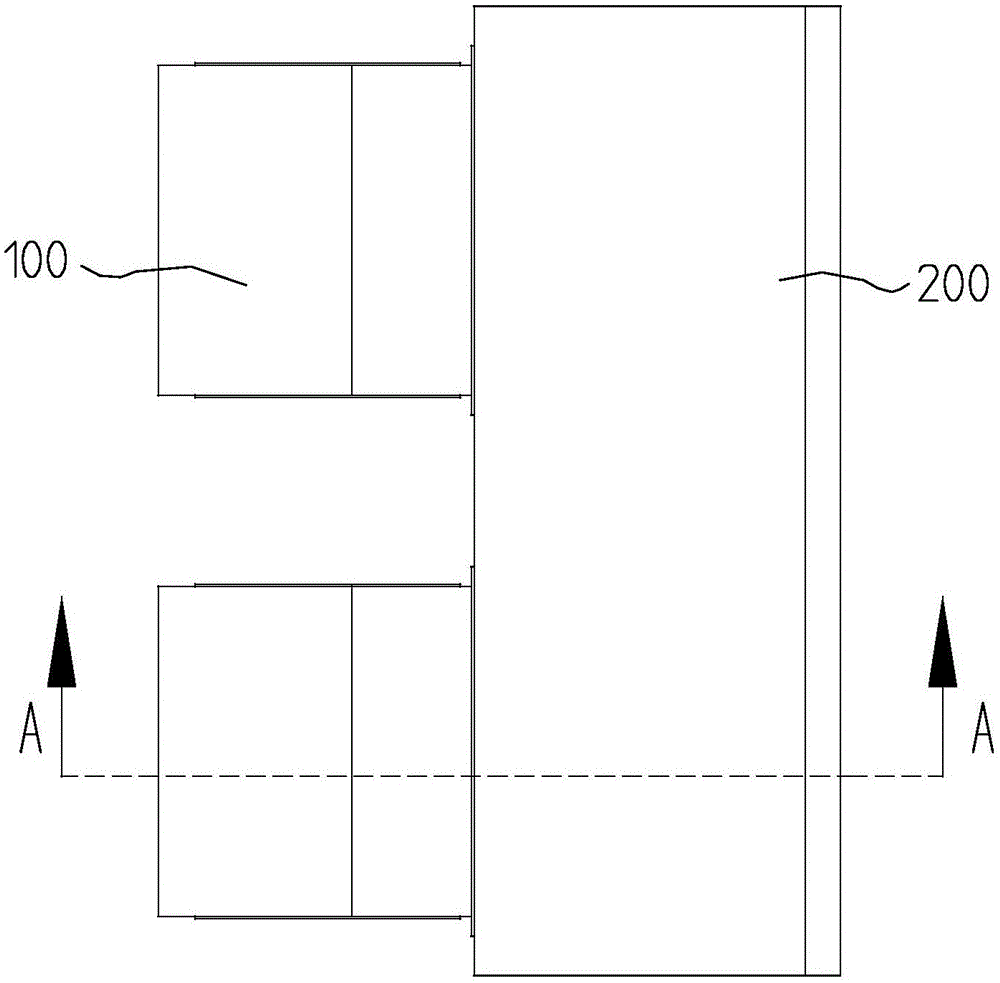

[0037] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0038] Such as Figure 4 to Figure 10 As shown, the present invention is a coil fan structure, including a blower 1, a fan box 2 and a heat exchanger 3, the blower 1 includes a volute 11, a wind wheel 12 and a motor 13, and the wind wheel 12 is installed on the volute Inside the first cavity 111 of the casing 11, the volute 11 is provided with a first air inlet 112 and a first air outlet 113, and the output shaft 131 of the motor 13 extends into the first cavity 111 and is connected with the wind wheel 12 for installation. The box body 2 is provided with a second cavity 21, one side of the fan box body 21 is provided with a second air inlet 22, the other side of the fan box body 2 is provided with a second air outlet 22, and the heat exchanger 3 is installed in the second cavity 21 And between the second air inlet 22 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com