An underground self-advancing high-pressure abrasive gas jet drilling repair device and method

A high-pressure gas and gas jet technology, which is applied to the driving device for drilling in the wellbore, drilling with liquid/gas jet, drill bit, etc., can solve the problem of blocking the gas extraction channel, advancing the termination time of gas desorption, and muddying the coal body, etc. problem, to achieve the effect of strong coal breaking ability, improved repair effect, and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

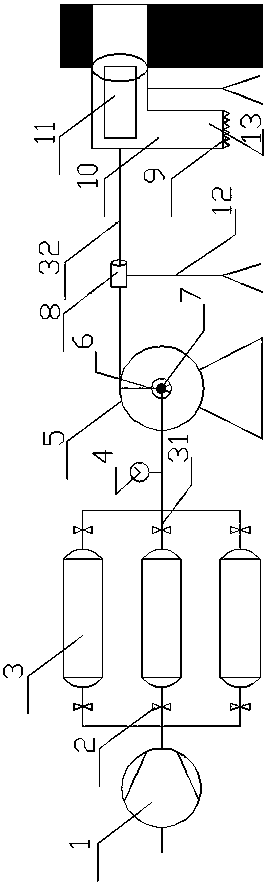

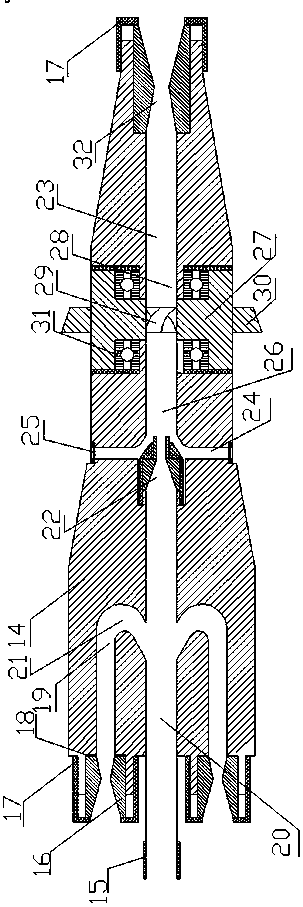

[0025] An underground self-feeding high-pressure abrasive gas jet drilling repair device, such as figure 1 As shown, a high pressure gas section is included for generating high pressure gas.

[0026] The high-pressure gas part includes an air compressor 1 and at least one gas cylinder 3 , and the number of gas cylinders 3 in this embodiment is three. The outlet of the air compressor 1 is connected to the inlet of each gas cylinder 3, so that the gas in the air compressor enters the gas cylinder. In order to facilitate gas control, a valve 2 is provided on both the inlet and the outlet of the gas cylinder 3, and the control process of gas transmission is facilitated by opening or closing the valve 2. At the same time, a hose is connected to the outlet of the gas cylinder 3, and a pressure gauge 4 is arranged on the hose. The pressure of the gas in the hose can be known through the pressure gauge 4. By monitoring the gas parameters, the entire work can be monitored in time. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com