Pipe winding guide mechanism

A guiding mechanism and the technology of winding the tube, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as inconvenience, and achieve the effect of evenly winding the tube and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

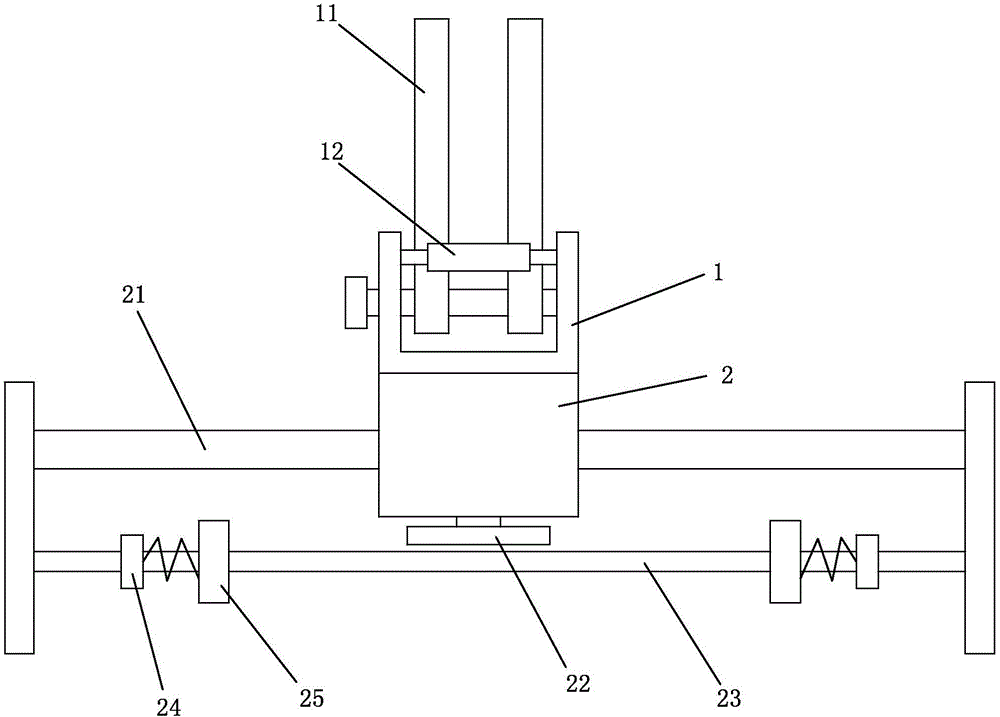

[0011] refer to figure 1 , a pipe winding guide mechanism of the present invention, comprising a limit frame 1 and a moving seat 2, the limit frame 1 is fastened on the moving seat 2, and the limit frame 1 is provided with at least two vertical guides The column 11 and the transverse guide rod 12, the moving seat 2 is movably nested on the transverse round rod 21, the limit frame 1 restricts the shaking of the pipe when the pipe is wound, so that the pipe is coiled along the pipe winding equipment or the pipe winding At the same time, the moving seat 2 moves left and right along the winding process to keep the pipe material straight around the pipe.

[0012] As an improvement of the above-mentioned embodiment, the limit frame 1 is screwed to the guide post 11 through a transverse bolt, and the guide post 11 moves along the rotation of the bolt to merge and separate, so that it can be adjusted to accommodate pipes of different widths.

[0013] As a further improvement of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com