A mold car steering device

A steering device and mold car technology, applied in transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of production line layout, actual production impact of enterprises, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings, so as to facilitate the clear understanding of those skilled in the art.

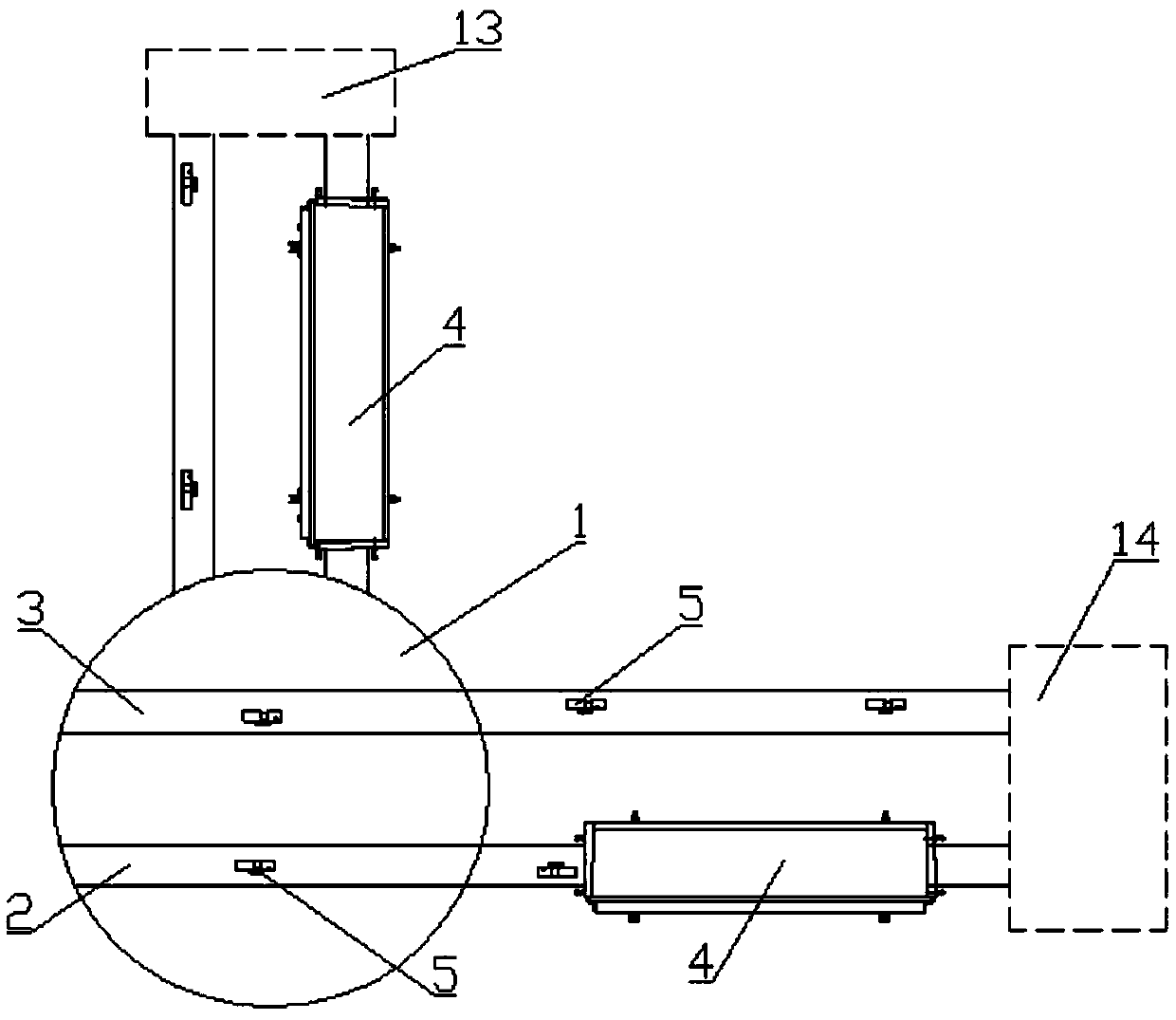

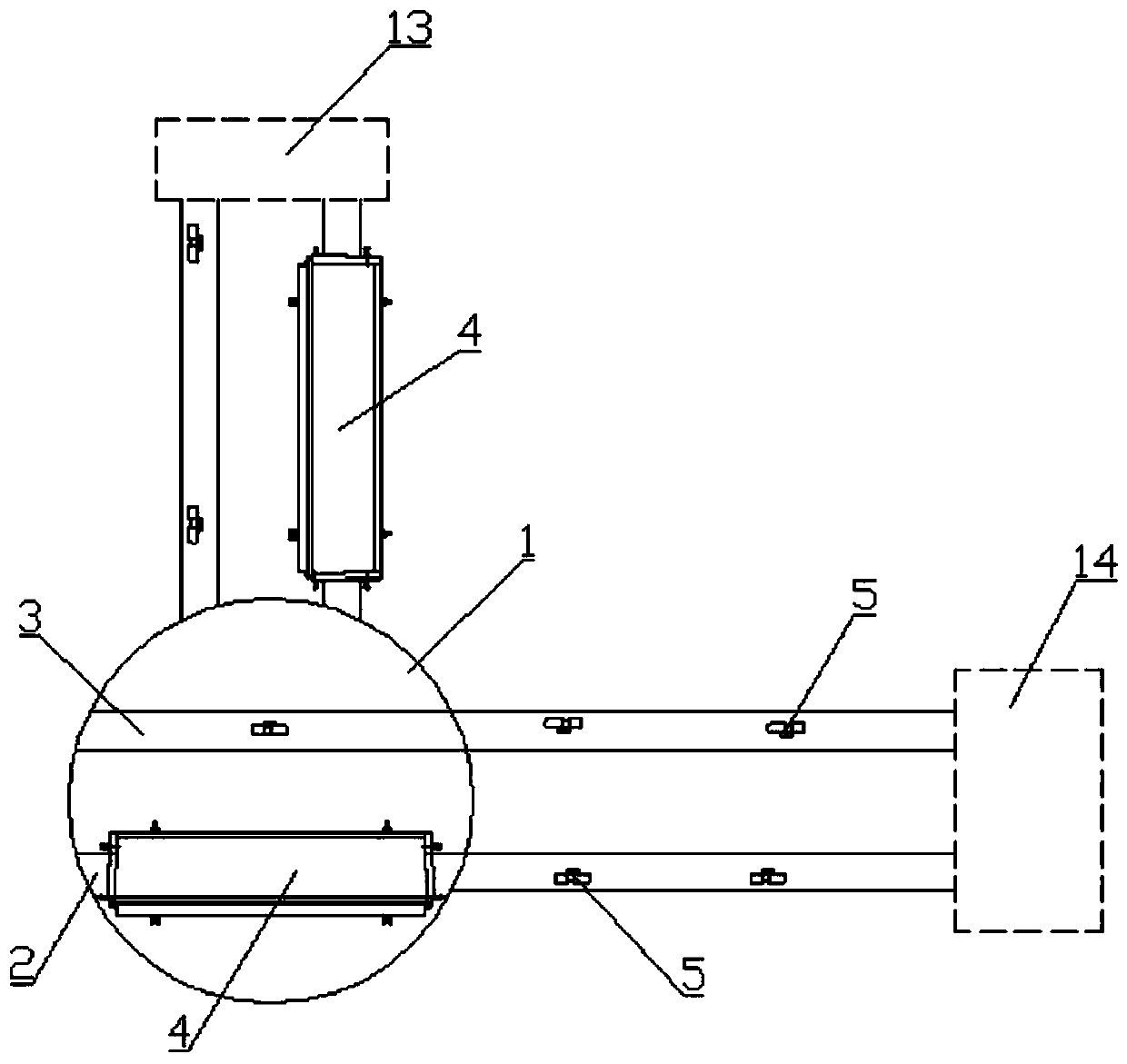

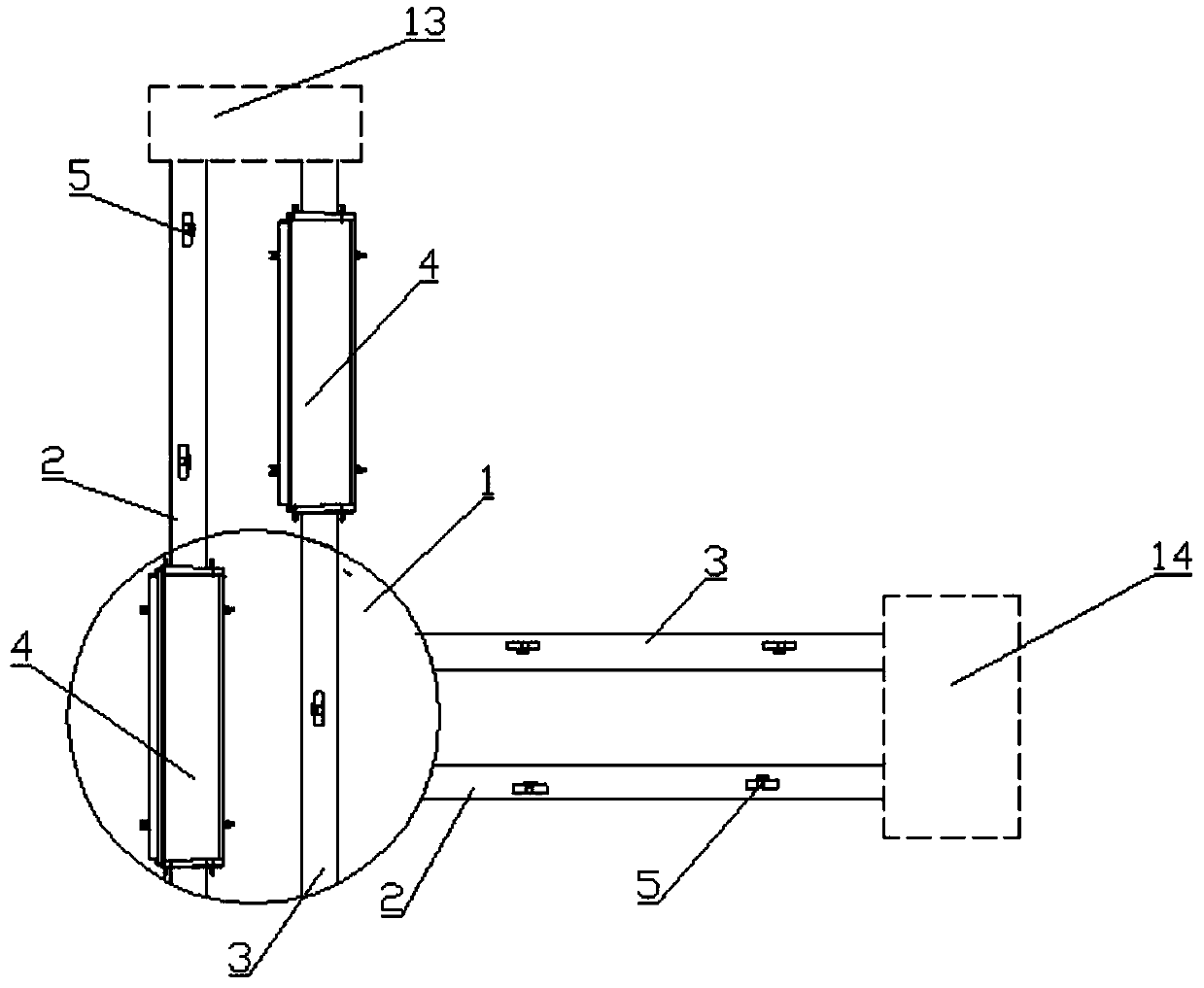

[0019] like figure 1 As shown, the present invention includes:

[0020] Rotating platform 1, ascending track 2, descending track 3, die car 4, friction wheel 5;

[0021] The rotating platform 1 includes a positioning mechanism and a limiting mechanism;

[0022] like Figure 7 As shown, the positioning mechanism includes a positioning cylinder 6, a first positioning hole 7, a second positioning hole 12, and a cylinder controller (not shown in the figure), and the positioning cylinder 6 is connected to the bottom of the rotating platform 1; the The first and second positioning holes 7 and 12 are arranged on the peripheral wall of the cylindrical space accommodating the rotating platform 1 , and the first and second positioning holes 7 and 12 are separated by an arc length of 90 degrees. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com