Roller feeding bagging machine

A material bagging machine and a drum-type technology, applied in the field of drum-type material feeding and bagging machines, can solve the problems of bag wall dislocation, unsatisfactory heat sealing effect, and unequal pocket folds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

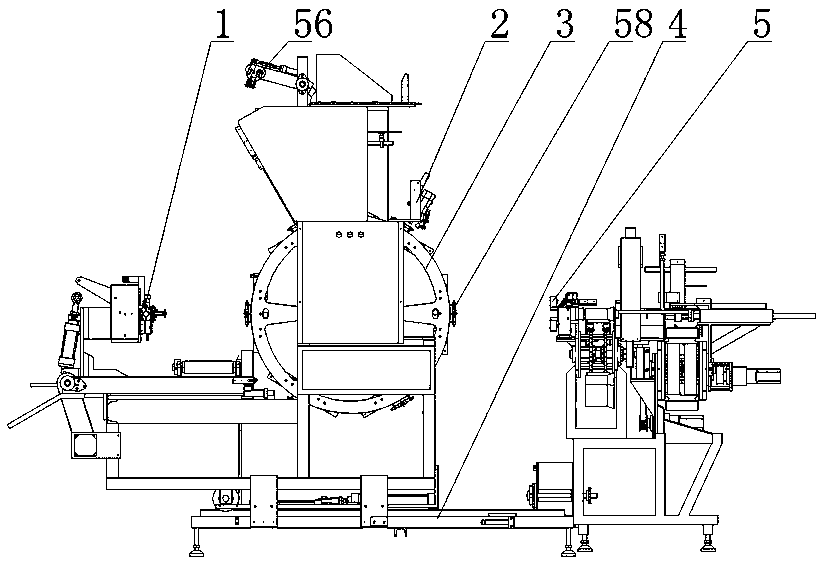

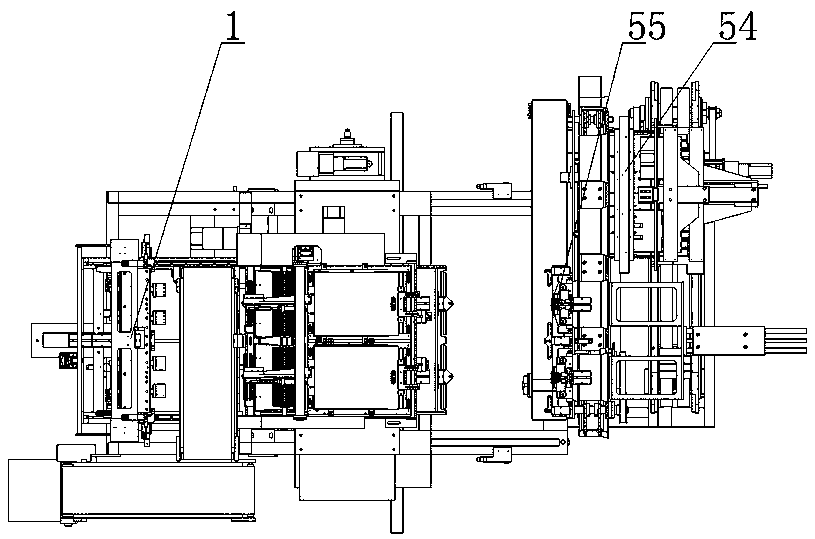

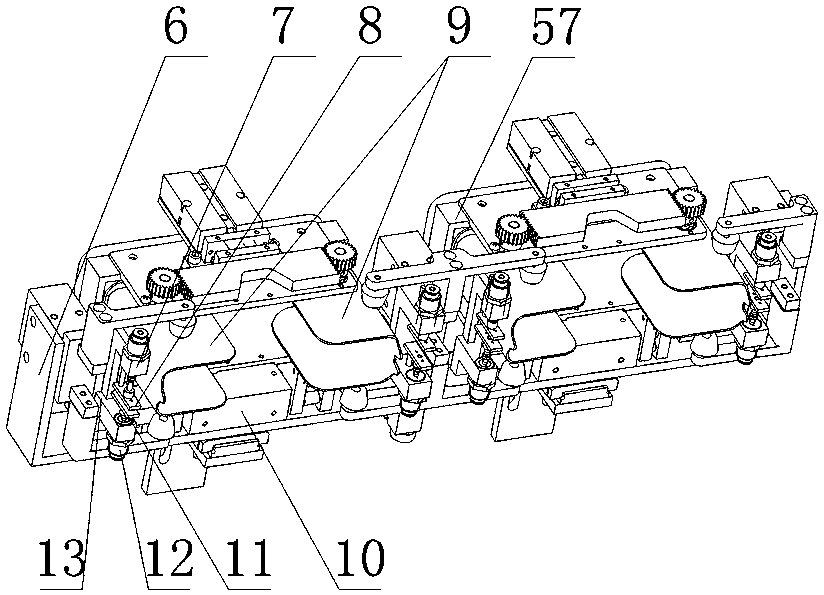

[0027] refer to figure 1 , this kind of drum-type feeding bagging machine has a frame 4 and a drum 3, and a bag feeding device 56 and a heat-sealing device 30 are arranged on the outside of the drum 3, and working grooves are evenly distributed on the drum 3, so The feeding place of the bagging machine is provided with a bag-supporting mechanism 55, and the bag-supporting mechanism 55 has a bag-supporting frame 57, and U-shaped bag-supporting rods 9 are arranged on both sides of the bag-supporting frame 57. A bag opening mechanism 58 is provided at the place, and a packing bag tightening mechanism is provided on one side of the U-shaped bag support rod 9, and a rubbing bag mechanism 2 is provided above the working tank, and at the discharge place of the working tank 3 A pull bag mechanism 1 is provided.

[0028] The above-mentioned bag-feeding device, heat-sealing device, bag-opening mechanism and bag-supporting mechanism are all prior art, and will not be described in detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com