Unidirectional coupling overspeed brake-type minecart with a toothed brake rail

An overspeed brake and brake rail technology, applied in the field of coal mine machinery and equipment, can solve the problems of failure, misoperation, time-consuming and laborious handling of accidents, etc., and achieve the effects of low cost, easy installation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

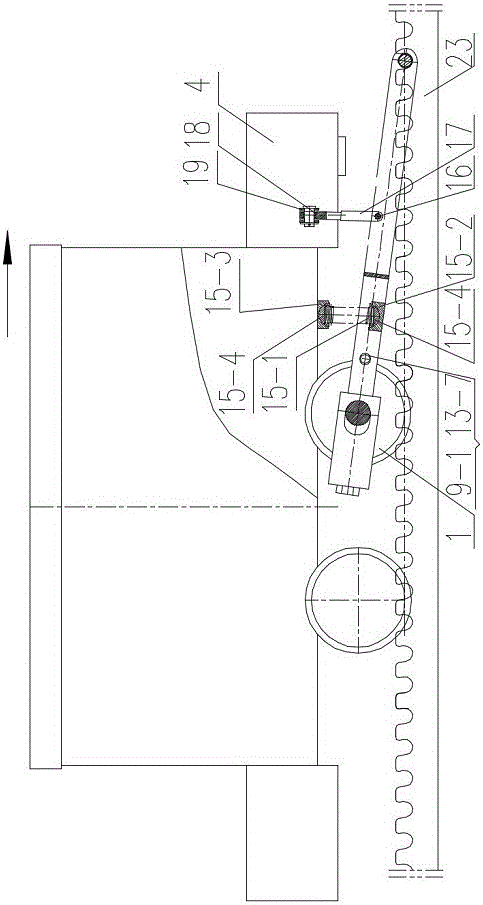

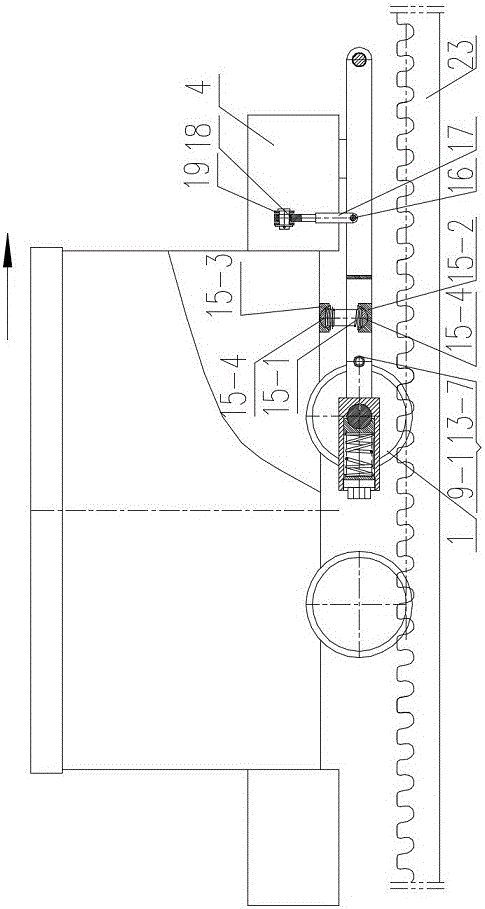

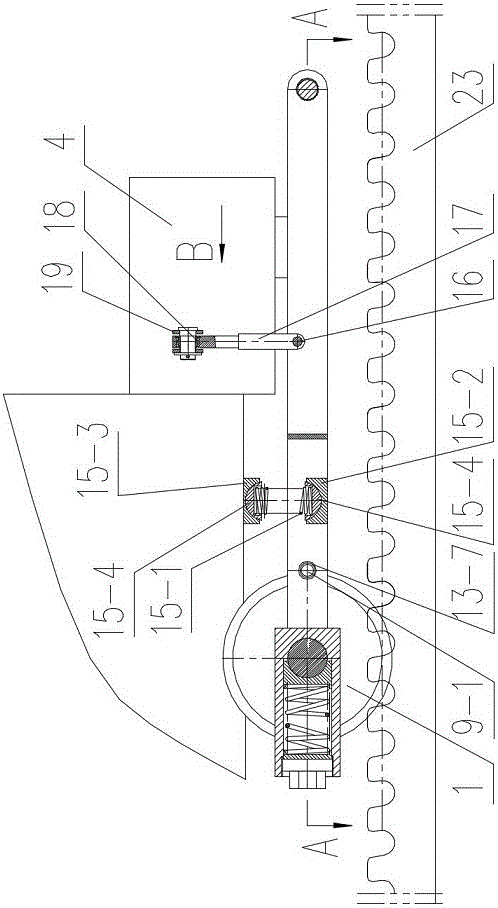

[0027] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the direction facing the mine car body relative to the direction of the mine car body is the inner side, and the direction away from the mine car body is the outside description).

[0028] Such as Figure 1 to Figure 4 As shown, the one-way hook overspeed braking mine car with toothed brake rails includes brake anti-sports car parts, and the brake anti-sports car parts are installed on the frame 4 in the forward direction of the mine car, and the direction of the arrow is the mine car In the forward direction, the toothed brake rail 23 is arranged parallel to the mine car track, and is fixedly installed between two mine car tracks. The upper plane of the toothed brake rail 23 is provided with uniformly distributed toothed structures along the front and rear directions.

[0029] The anti-car braking device includes a speeding car information collection and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com