High-strength anti-breaking cable bracket for bogie

A bogie, high-strength technology, applied in the direction of bogie, railway car body parts, transportation and packaging, etc., can solve the problems of unsuitable outlet interface, high vibration and impact acceleration, prone to fatigue fracture, etc., so as to facilitate production and improve Good safety and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

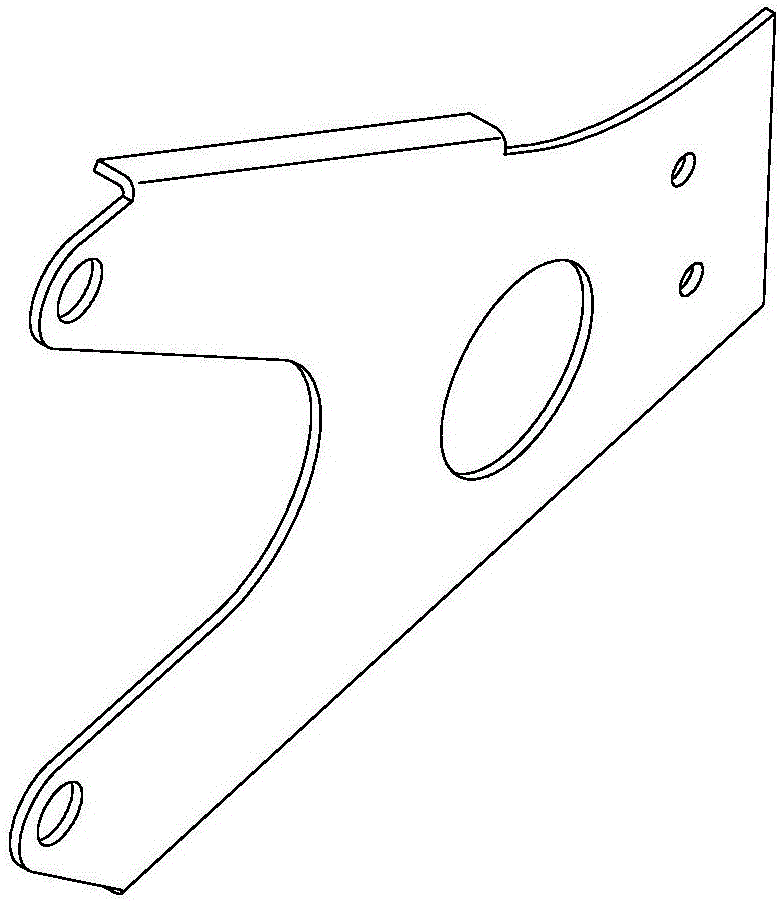

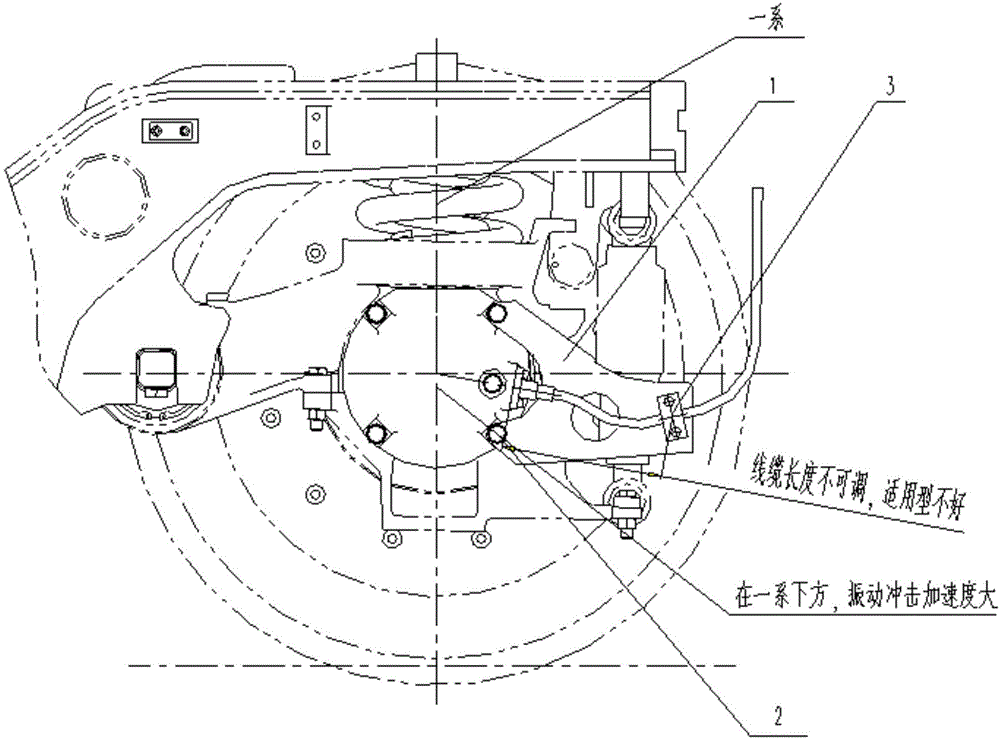

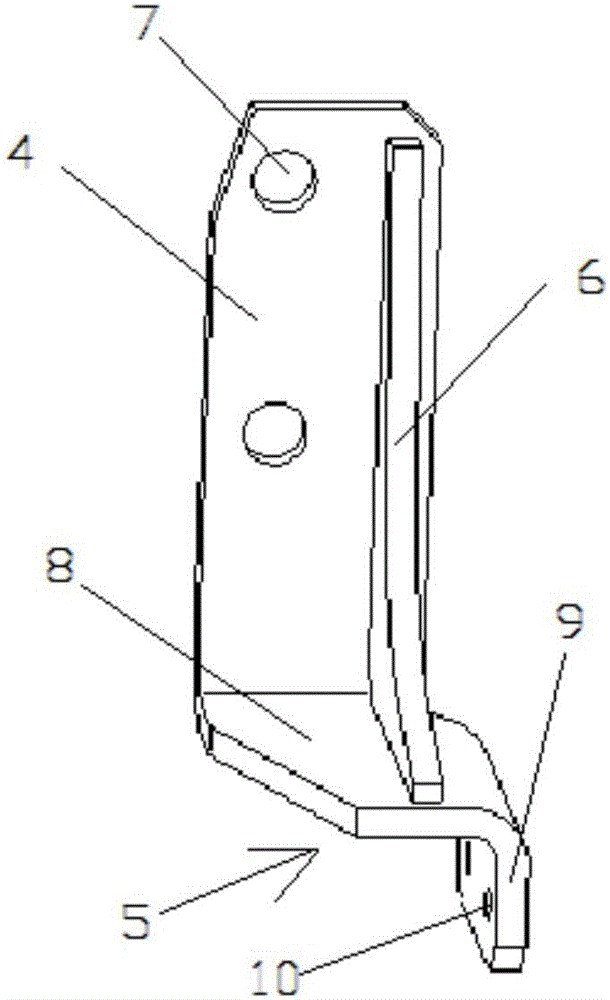

[0018] Such as image 3 , Figure 4 As shown, it is a high-strength anti-break cable bracket for a bogie, which has a mounting plate 4, a cable fixing plate 5 and a vertical connecting plate 6. The mounting plate 4 is provided with a round hole 7, and is fixed to the end of the side frame of the bogie by bolts 12; the cable fixing plate 5 is an L-shaped bending part, and has a horizontal plate 8 and a vertical plate 9, and the horizontal plate 8 is close to the bogie One side of the end of the side frame is welded to the lower part of the mounting plate 4, the side of the vertical connecting plate 9 close to the end of the bogie side frame is welded to the outside of the front end of the mounting plate 4, and the lower edge of the vertical connecting plate 9 is welded to the horizontal plate 8 The upper surface of the upper surface, the cable fixing plate 9 is located below the outside of the bogie side frame end, the cable fixing plate 9 has a cable fixing plate 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com