Tri-axle axle load distribution control system

A control system and axle technology, applied in the direction of vehicle springs, vehicle components, elastic suspension, etc., can solve the problems of complicated circuit connection and air circuit connection, increase the limit driving force of drive axle, increase the pressure of drive axle air bag, etc. Achieve the effects of simple structure, low production cost and reduced tire wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

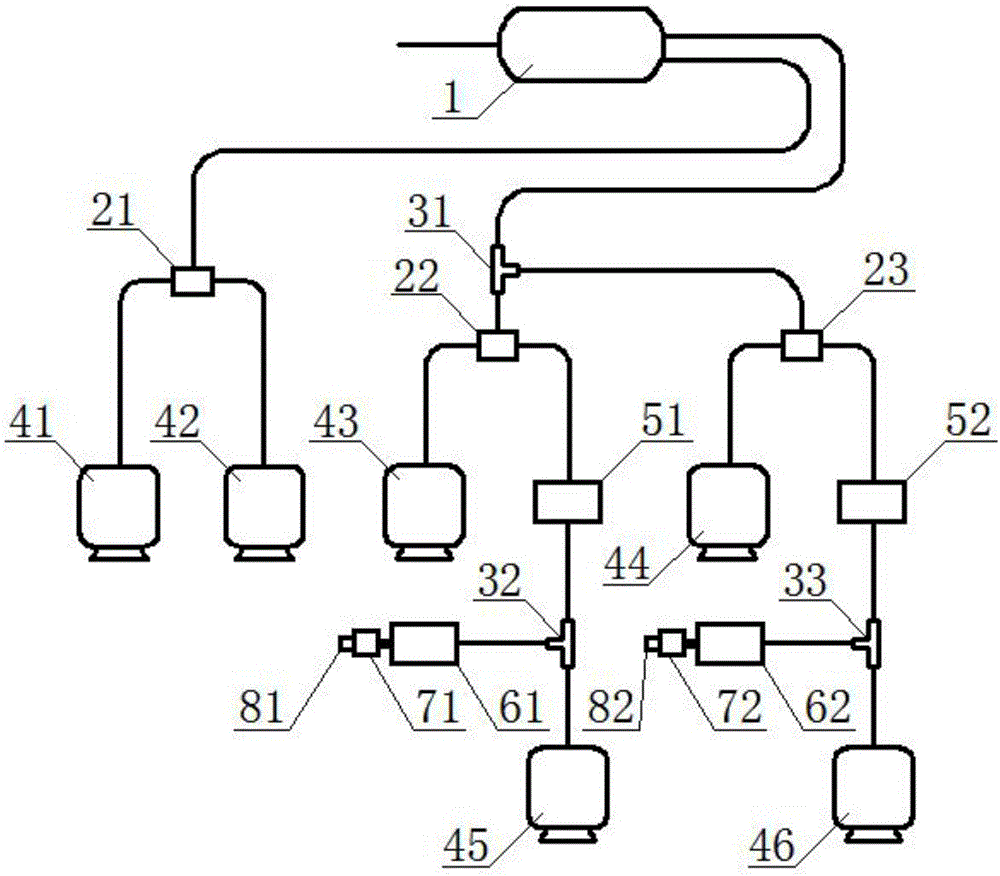

[0014] Such as figure 1 As shown, a three-axle passenger car axle load distribution control system includes an air reservoir 1, a first height valve 21, a second height valve 22, a third height valve 23, a first three-way joint 31, and a second three-way joint 32 , the third tee joint 33, the left airbag of the front axle 41, the right airbag of the front axle 42, the left airbag of the drive axle 43, the right airbag of the drive axle 44, the left airbag of the drive axle 45, the right airbag of the drive axle 46, the first normally open Solenoid valve 51, second normally open solenoid valve 52, first normally closed solenoid valve 61, second normally closed solenoid valve 62, first pressure limiting valve 71, second pressure limiting valve 72, first muffler 81, second Muffler 82 and controller; the input end of the air storage tank 1 is provided with a pressure protection valve, and the output end of the air storage tank 1 is respectively connected to the input end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com