Film-free paperboard natural curing production equipment

A production equipment and cardboard technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of affecting the strength of cardboard, insufficient natural curing time, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

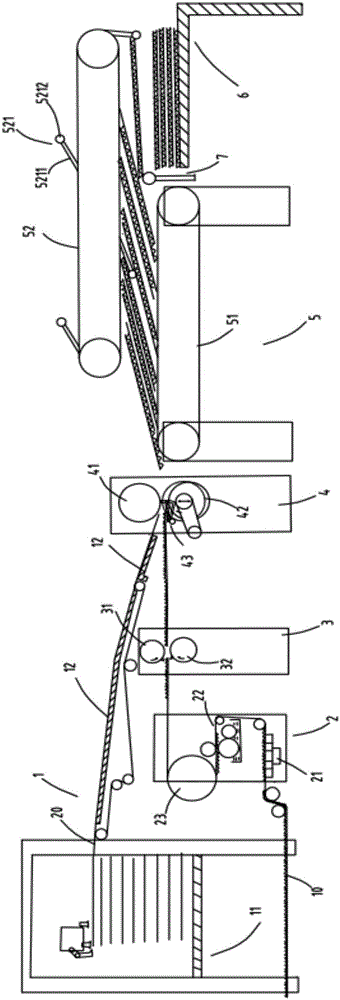

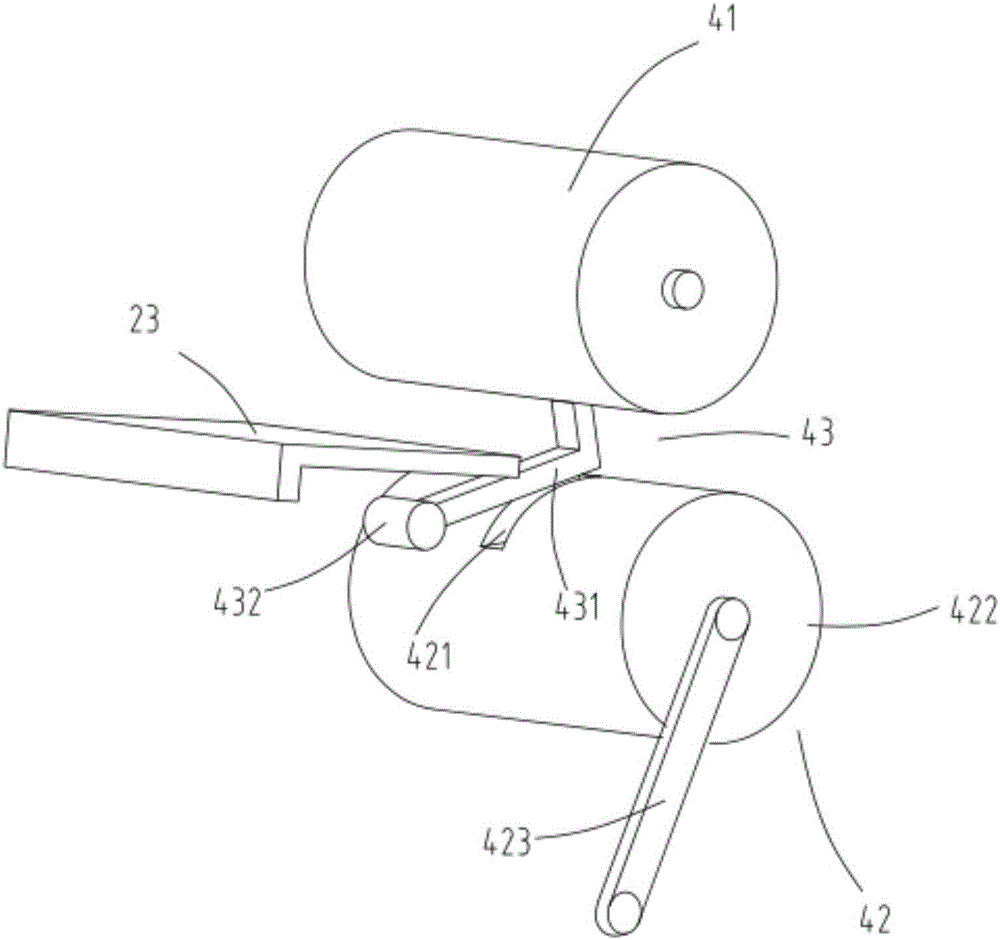

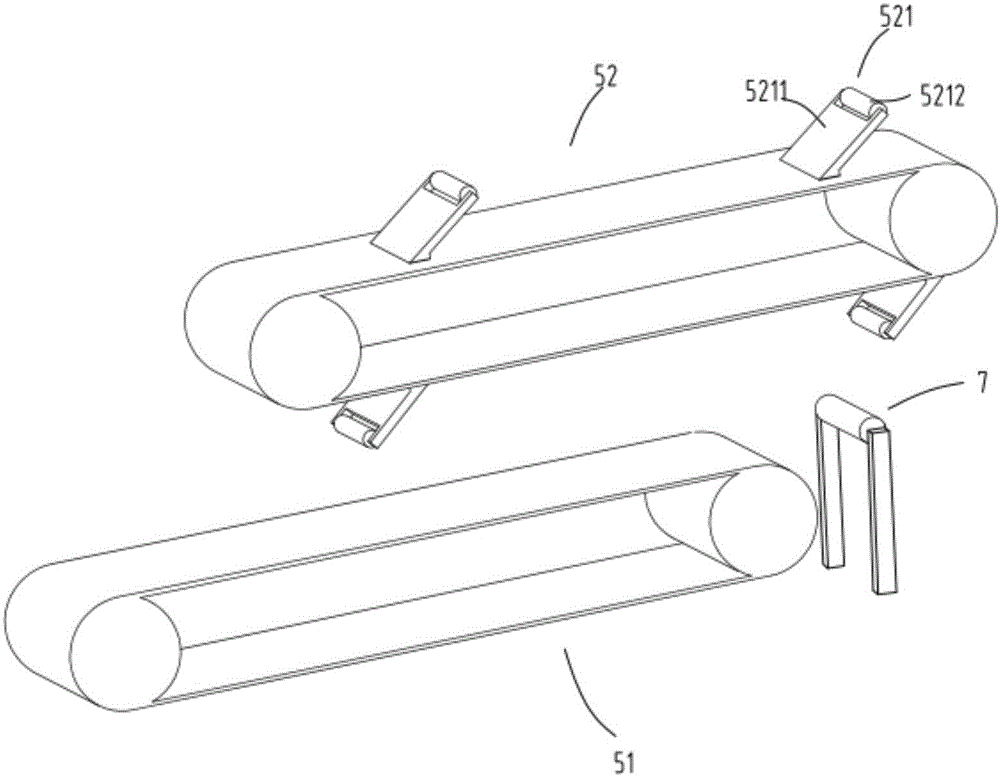

[0024] figure 1 It is a schematic diagram of the production equipment for natural curing of filmless paperboard, figure 2 It is a schematic diagram of the positioning pressing part, image 3 It is a schematic diagram of the upper conveyor belt and the lower conveyor belt. Such as figure 1 , figure 2 , image 3 As shown, what is provided in this embodiment is a natural curing production equipment for filmless cardboard, including a face paper conveying part 1, a corrugated paper pretreatment part 2, a corrugated paper cross-cutting machine 3, a positioning pressing part 4 and a lamination curing conveying part 5 ; The facial paper conveying part 1 is arranged at the front end and the upper end of the corrugated paper pretreatment part 2; the corrugated paper cross cutting machine 3 is arranged at the rear end of the corrugated paper pretreatment part 2; machine 3 and the rear end of the facial paper conveying part 1; the lamination and curing conveying part 5 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com