Special-shaped curve silicone injection molding machine screw

An injection molding machine screw and special-shaped technology, which is applied in the field of special-shaped curve silicone injection molding machine screws, can solve the problems of short life, easy failure, and limited improvement effect of silicone injection molding screws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

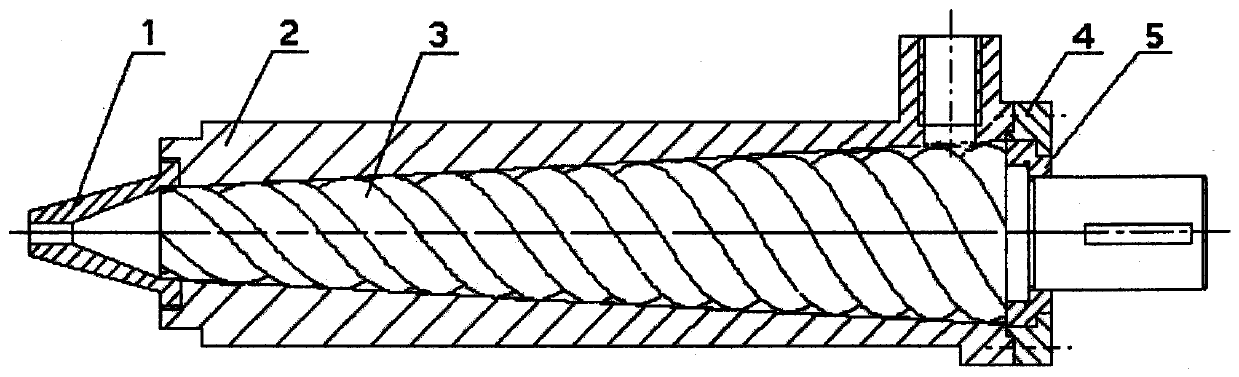

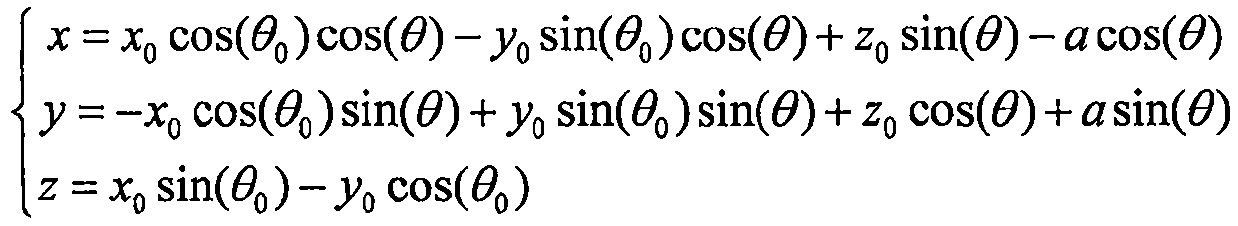

[0015] The implementation examples of the special-shaped curve silicone injection molding machine screw of the present invention are shown in the accompanying drawings. The invention adopts the special-shaped curve to rotate along the cone to form a non-cylindrical equal-pitch helical curved surface. The special-shaped curve parameters, screw pitch and screw cone taper of the special-shaped curve screw 3 are set according to the requirements of injection molding volume and injection pressure. See attached figure 2 , The actual device of the present invention is composed of: injection chamber 1, pump body 2, special-shaped curved screw rod 3, pump cover 4, and big-end sealed thrust bearing 5. The motor drives the special-shaped curve screw 3 to rotate in the pump body 2, and the heated silica gel material enters the pump body 2 from the feed port on the pump body, and is pushed to the injection chamber 1 by the helical surface groove of the special-shaped curve screw 3, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com