High-throughput multi-modal characterization system and method based on micro-nano manipulation robot

A multi-mode and robot technology, applied in the field of high-throughput multi-mode characterization system, can solve the problems of single characterization mode and low characterization efficiency, and achieve the effect of fast control speed and high characterization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention.

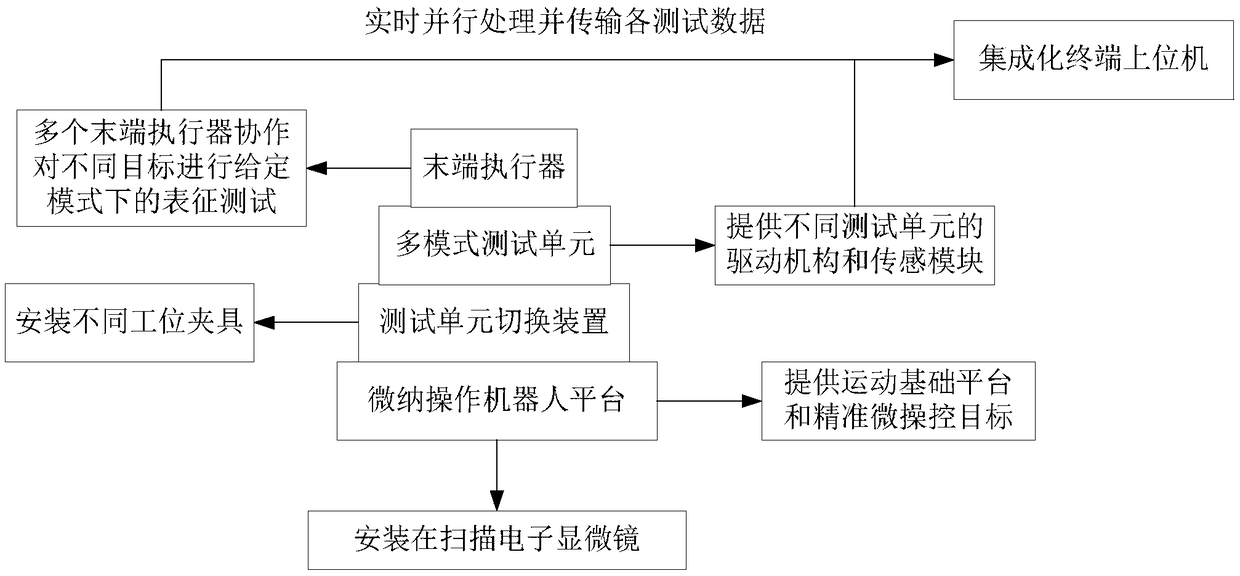

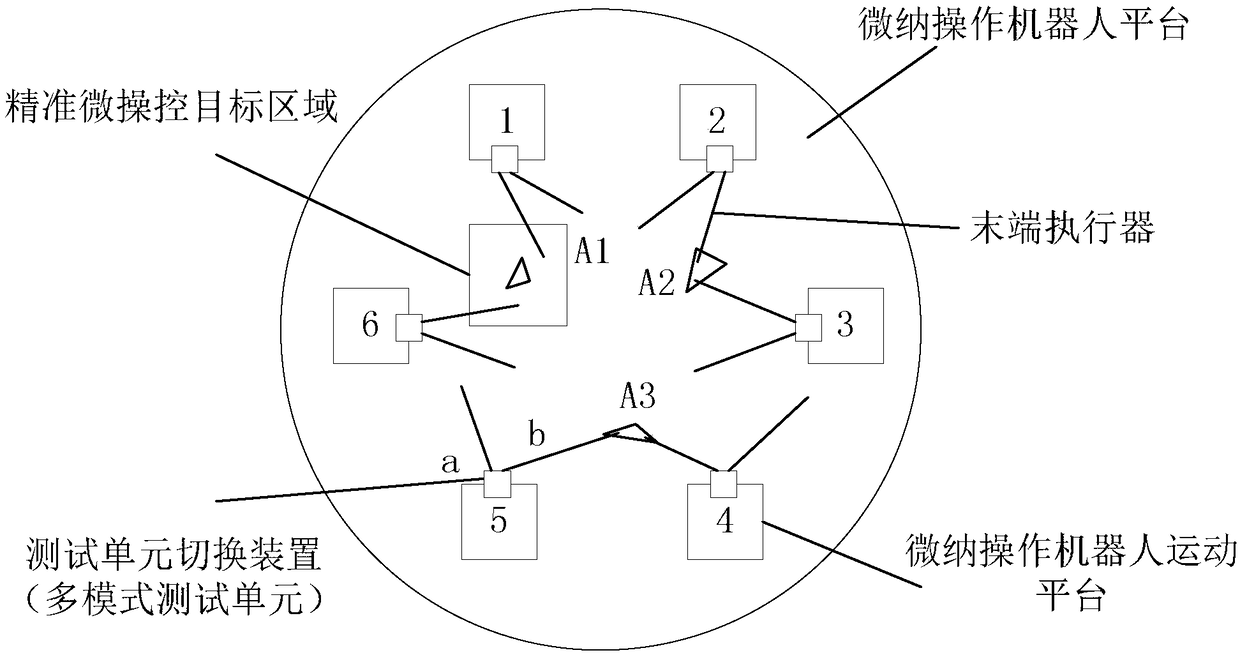

[0021] See Figure 2 ~ Figure 3 , A high-throughput multi-mode characterization system based on a micro-nano manipulating robot, applied under a scanning electron microscope, the micro-nano manipulating robot is installed in the scanning electron microscope, and the motion platform of the micro-nano manipulating robot is respectively installed with a test unit switch The device and the multi-mode test unit are respectively fixedly connected to different station fixtures of the test unit switching device, and different end effectors are respectively installed on the multi-mode test unit.

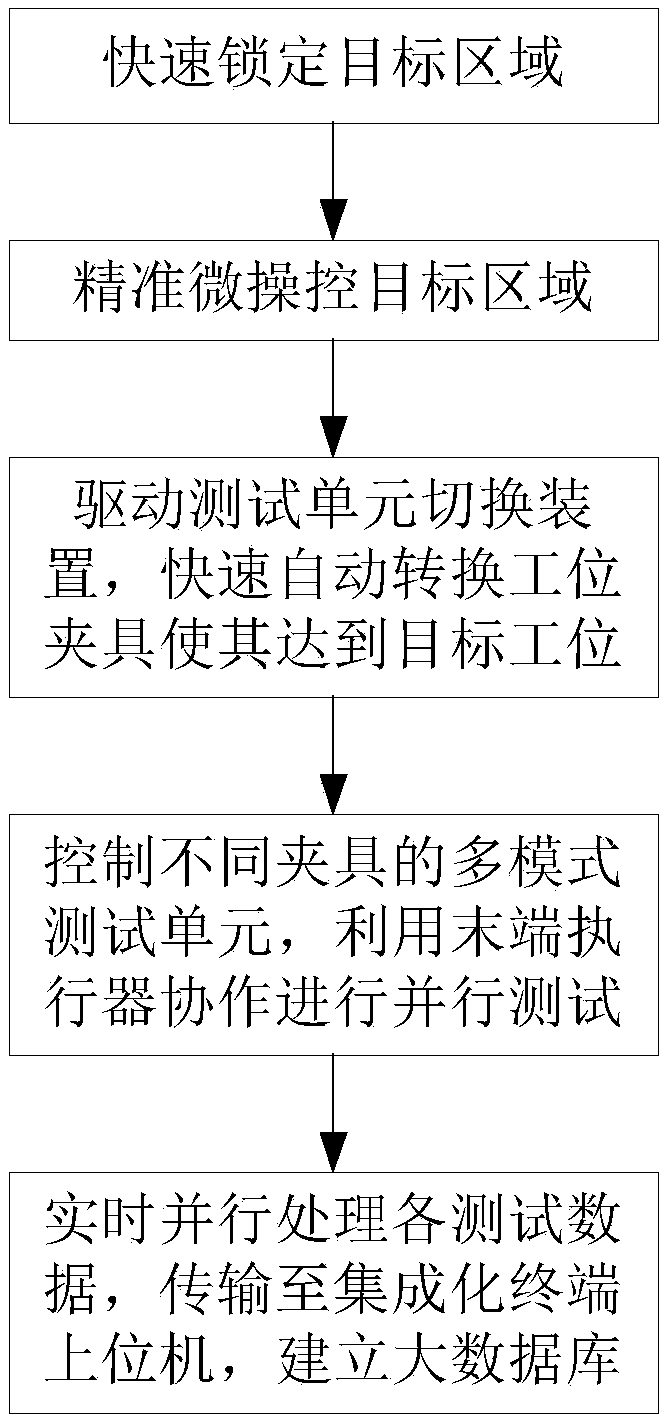

[0022] See Figure 1 ~ Figure 4 , A high-throughput mechanoelectric mode characterization method based on micro-nano manipulating robots, using the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com