Fertilizer drum mixer with detachable mixing blades

A technology of mixing blades and mixing drums, which is applied in the direction of mixer accessories, mixers with rotating containers, mixers, etc., can solve the problems of large fluctuations in the production time of organic fertilizers, easy pollution of the mixing drum environment, and long waste of time. It is convenient and quick to manufacture, improves the efficiency of drying and sterilization, and is convenient for storage and stretching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

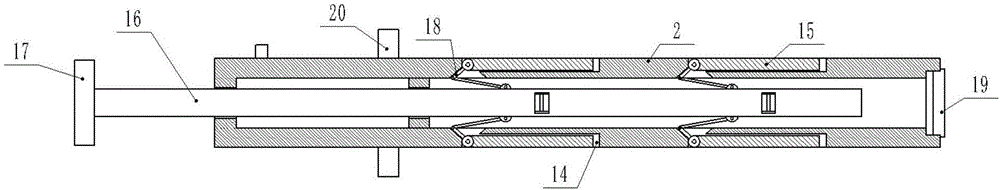

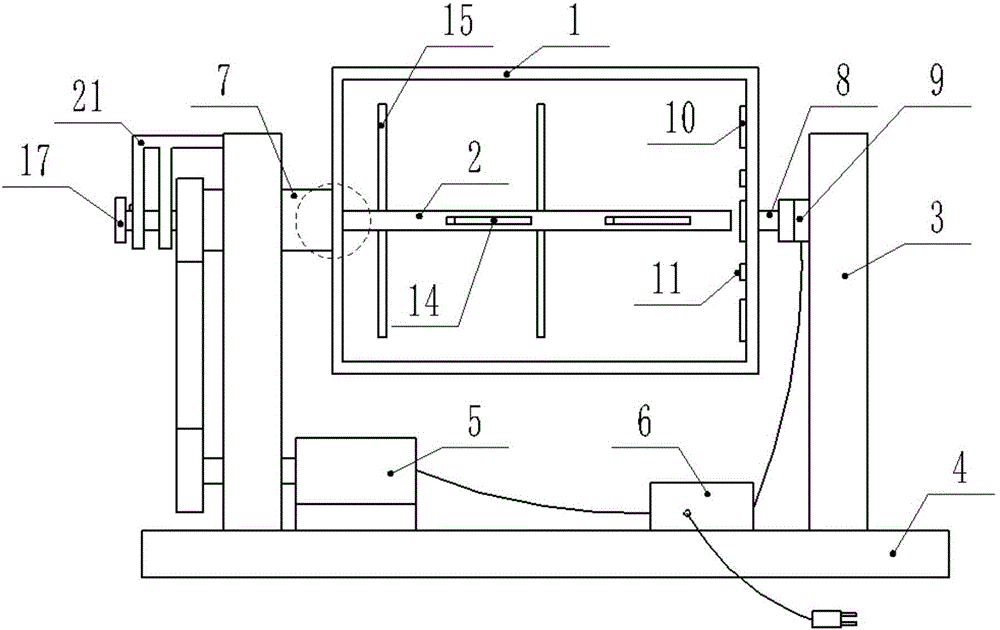

[0014] see Figure 1-3 , a fertilizer drum mixer with mixing blades disassembled, comprising a mixing drum 1 and a stirring shaft 2, the drum wall of the mixing drum 1 is hingedly connected with a drum door for feeding in and out of materials, and the rotating shaft of the mixing drum 1 is connected to a bracket 3, The bracket 3 is fixedly connected to the upper end of the base 4, the base 4 is fixedly connected with an electric motor 5, and the base 4 is also fixedly connected with a ballast 6, the electric motor 5 is electrically connected with the ballast 6, and the ballast 6 After the voltage is stabilized, the electric motor 5 is powered. The left side wall of the mixing drum 1 is fixedly connected with a hollow driving shaft 7. The driving shaft 7 is connected to the electric motor 5 through the belt pulley fixedly connected at the left end, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com