Coal-fired power plant smoke gas circulating adsorbent demercuration device and demercuration method

A flue gas circulation, coal-fired power plant technology, applied in separation methods, combined devices, chemical instruments and methods, etc., can solve the problems of affected fly ash quality, high cost of mercury removal technology, equipment corrosion, etc. The effect of reducing the cost of mercury removal and preventing secondary pollution of mercury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

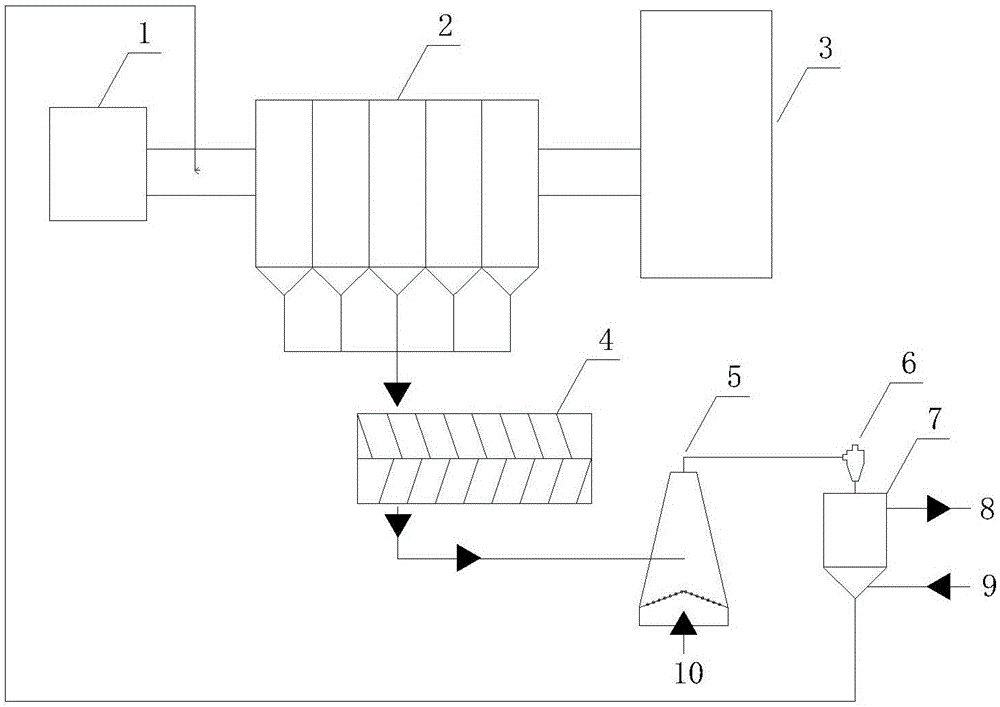

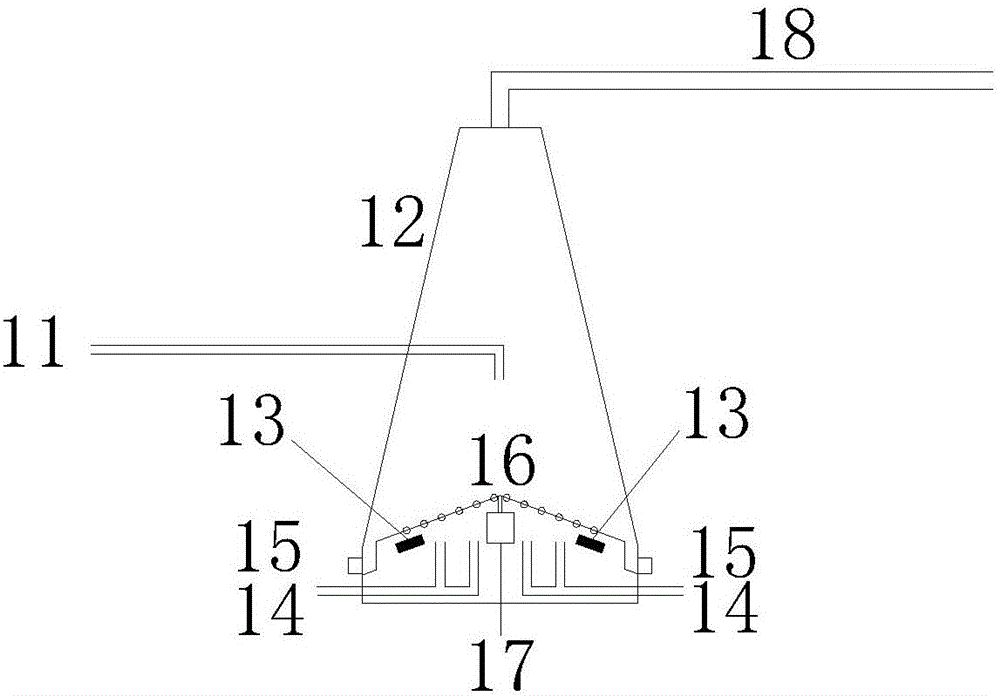

[0021] Such as figure 1 As shown in the present invention, a method for removing mercury by a flue gas circulation adsorbent in a coal-fired power plant, selects magnetic activated carbon as the flue gas mercury removal adsorbent, sprays it into the flue behind the air preheater 1 to remove mercury in the flue gas, and then simultaneously The ash is collected together by the electrostatic precipitator 2, and the magnetic activated carbon and the magnetic substances in the ash are separated by the magnetic separator 4 at the bottom of the ash bin. Using the principle that the density of the magnetic substance in the ash is greater than that of the magnetic activated carbon, the mixture passes through the conical separator 5. Separation, the adsorbent with lower density is carried by the compressed air 10, discharged from the top of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com