Processing technology for black tea

A processing technology, black tea technology, applied in the field of black tea processing technology, can solve the problems of black tea quality reduction, uncontrollable fermentation temperature and time, etc., and achieve the effect of strong aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

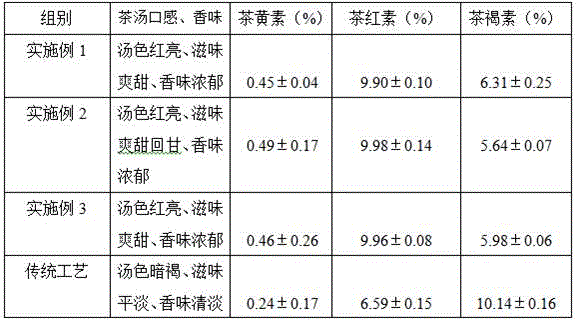

Examples

Embodiment 1

[0020] Embodiment 1: the processing technology of black tea, comprises the following steps:

[0021] a. Withering: put the fresh leaves in the withering tank and wither until the water content is 60-65%;

[0022] b. Shaking green: control the temperature in the shaking green room at 24-26°C, and the relative humidity is 95%; put the tea leaves in step a in the green shaking machine, and shake green green four times: the first shake green 30rad, after standing for 25min , shake green 120rad for the second time, stand still after 70min, shake green 150rad for the third time, stand still 100min, then carry out the fourth shake green, shake green 450rad;

[0023] c. Kneading: control the temperature in the kneading room at 20-24°C, and the relative humidity at 95%; the amount of leaves in the kneading machine should be 4-5kg / m 3 Drop into the tealeaves in step b, knead 30min;

[0024] d. Fermentation: Control the temperature in the fermentation room to 26-28°C, the relative humi...

Embodiment 2

[0026] Embodiment 2: the processing technology of black tea, comprises the following steps:

[0027] a. Withering: put the fresh leaves in the withering tank and wither until the water content is 60-65%;

[0028] b. Shaking green: control the temperature in the shaking green room at 24-26°C, and the relative humidity is 90%; place the tea leaves in step a in the green shaking machine, and shake green green for four times: the first shake green 50rad, after standing for 30min , Shake green 100rad for the second time, stand still after 60min, shake green 200rad for the third time, stand still 90min, then carry out the fourth shake green, shake green 400rad;

[0029] c. Kneading: control the temperature in the kneading room at 20-24°C, and the relative humidity at 90%; the amount of leaves in the kneading machine should be 4-5kg / m 3 Drop into the tealeaves in step b, knead 40min;

[0030] d. Fermentation: Control the temperature in the fermentation room to 26-28°C, the relative...

Embodiment 3

[0032] Embodiment 3: the processing technology of black tea, comprises the following steps:

[0033] a. Withering: put the fresh leaves in the withering tank and wither until the water content is 60-65%;

[0034] b. Shaking green: control the temperature in the shaking green room at 24-26°C, and the relative humidity is 85%; place the tea leaves in step a in the green shaking machine, and shake green green four times: the first shake green 80rad, after standing for 35min , Shake green 80rad for the second time, stand still after 50min, shake green 220rad for the third time, stand still 80min, then carry out the fourth shake green, shake green 350rad;

[0035] c. Kneading: Control the temperature in the kneading room at 20-24°C and the relative humidity at 85%; the amount of leaves thrown in the kneading machine should be 4-5kg / m 3 Drop into the tealeaves in step b, knead 50min;

[0036] d. Fermentation: Control the temperature in the fermentation room to 26-28°C, relative hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com