Green tea processing process

A processing technology and green tea technology, applied in the field of A23F3/34, can solve the problems of heavy green tea astringency, affecting the promotion and drinking of green tea, and heavy green tea, and achieve the effects of mellow taste, help gastrointestinal digestion, and mellow and sweet taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A processing technology for green tea. The green tea is composed of tea leaves, cassia cotyledons, ginkgo leaves and sweet grass leaves. The mass-to-number ratios of the raw materials are: 45 parts of tea leaves, 6 parts of cassia cotyledons, and 4.5 parts of ginkgo leaves. part, 3.5 parts of sweet grass leaves, and the processing technology comprises the following steps:

[0032] The first step, screening: select the full-bodied tea leaves, cassia cotyledons, ginkgo leaves and sweet grass leaves from the raw materials;

[0033] The second step, washing and drying: the tea leaves, cassia cotyledon leaves, ginkgo leaves and sweet grass leaves selected in the first step are washed and dried;

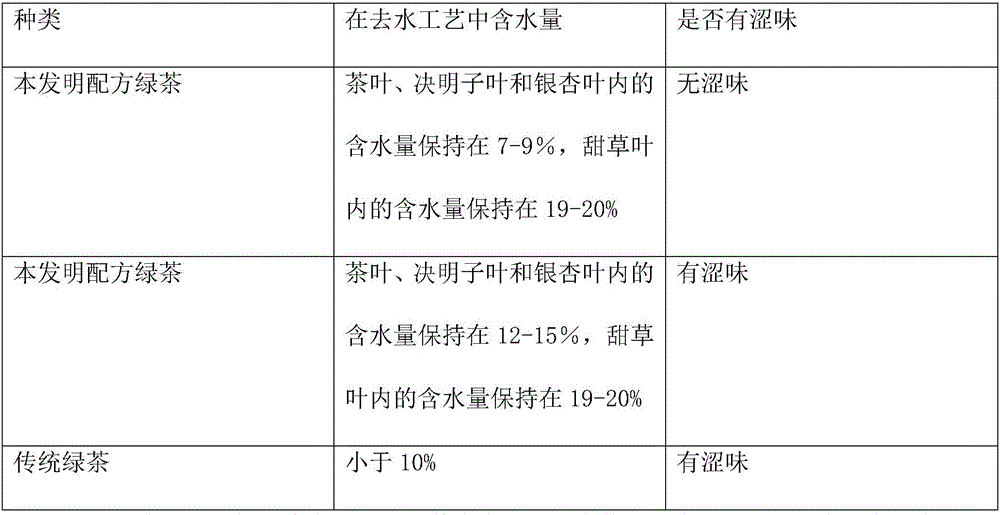

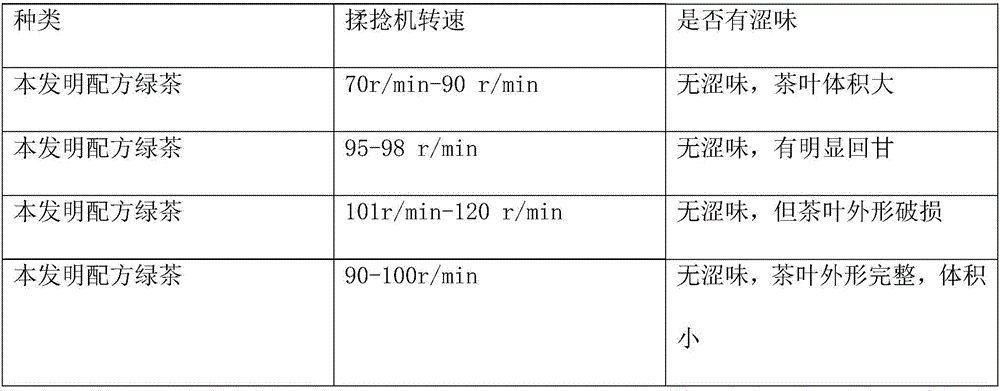

[0034] The third step is to remove water: evaporate part of the water in the tea leaves, cassia cotyledons, ginkgo leaves and sweet grass leaves by high temperature to soften the leaves and create conditions for kneading and shaping, so that the water content in the tea leaves, cass...

Embodiment 2

[0053] The difference from Example 1 is that the number of tea leaves is 50 parts, cassia cotyledon leaves are 8.5 parts, ginkgo leaves are 6 parts, and sweet grass leaves are 1.5 parts. The green tea under this formula has a slightly sweet taste and no astringency. The water content in the tealeaves, cassia leaves and ginkgo leaves in the three steps remains on 7%, the water content in the sweet grass leaves remains on 20%, and the rotating speed of the kneading machine is 90r / min.

Embodiment 3

[0055] The difference from Example 1 is: wherein the number of tea leaves is 46 parts, cassia cotyledon leaves are 5.5 parts, ginkgo leaves are 4.5 parts, sweet grass leaves are 2.5 parts, and the rotating speed of the kneading machine is 100r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com