Anchor layer formation composition, anchor layer, optical film provided with adhesive layer, and image display device

A technology of adhesive layer and anchoring layer, applied in the direction of ester copolymer adhesive, adhesive type, film/sheet adhesive, etc., which can solve problems such as peeling, floating, and increased shrinkage stress , to achieve the effects of improving adhesion, suppressing defects, and excellent reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

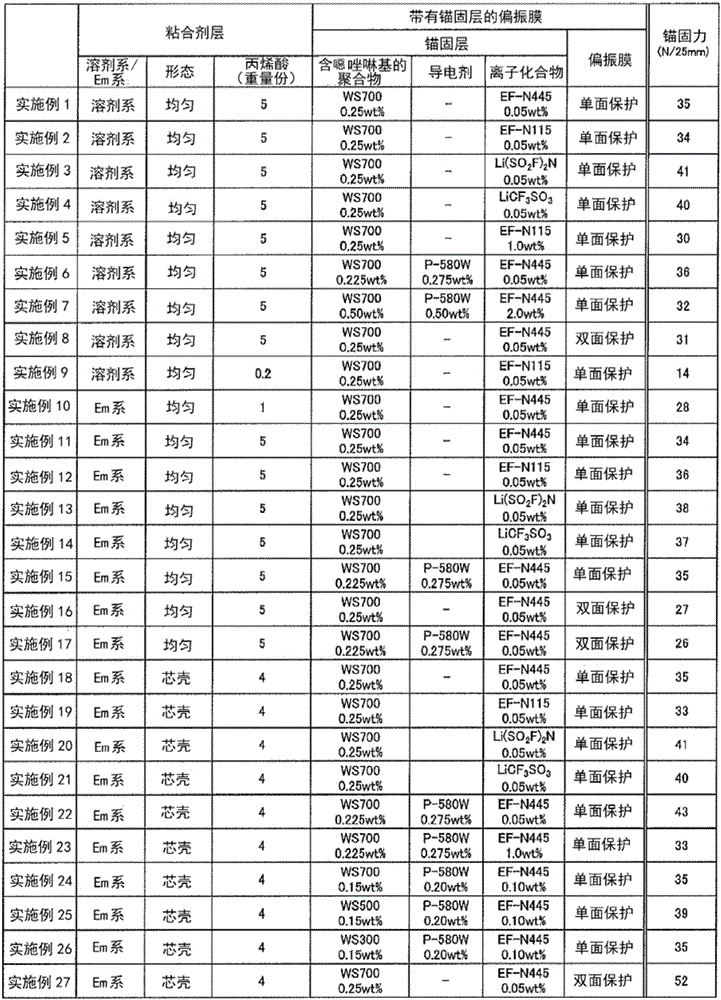

Embodiment 1

[0158] (Preparation of Adhesive Composition)

[0159] In a reaction vessel equipped with a cooling pipe, a nitrogen inlet pipe, a thermometer and a stirring device, 100 parts by weight of butyl acrylate, 5 parts by weight of acrylic acid, 0.075 parts by weight of hydroxyethyl acrylate, and relative to the monomer ( Solid content) 100 parts by weight of benzoyl peroxide (BOP) as an initiator was reacted at 60° C. for 7 hours under a nitrogen stream. Then, ethyl acetate was added to this reaction liquid, and the solution (30 weight% of solid content concentration) containing the (meth)acrylate copolymer with a weight average molecular weight of 1.6 million was obtained.

[0160] With respect to 100 parts by weight of the solid content of the obtained acrylate copolymer-containing solution (solid content concentration: 30% by weight), trimethylolpropane / toluene diisocyanate trimer adduct (trade name: : CORONATE L, manufactured by Nippon Polyurethane Industry Co., Ltd.) 0.6 parts...

Embodiment 2~7

[0166] An adhesive optical film was produced in the same manner as in Example 1 except that the composition of the anchor layer-forming composition (1) used in Example 1 was changed to the composition described in Table 1.

Embodiment 8

[0168] An adhesive type optical film was produced in the same manner as in Example 1, except that the single-sided protective polarizing film was changed to a double-sided protective polarizing film, and an anchor layer was formed on one protective film of the double-sided protective polarizing film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com