Gripping device, robot system and method for gripping workpieces

A technology of grasping device and industrial robot, applied in the direction of manipulator, manufacturing tool, chuck, etc., can solve problems such as clamping jaw injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

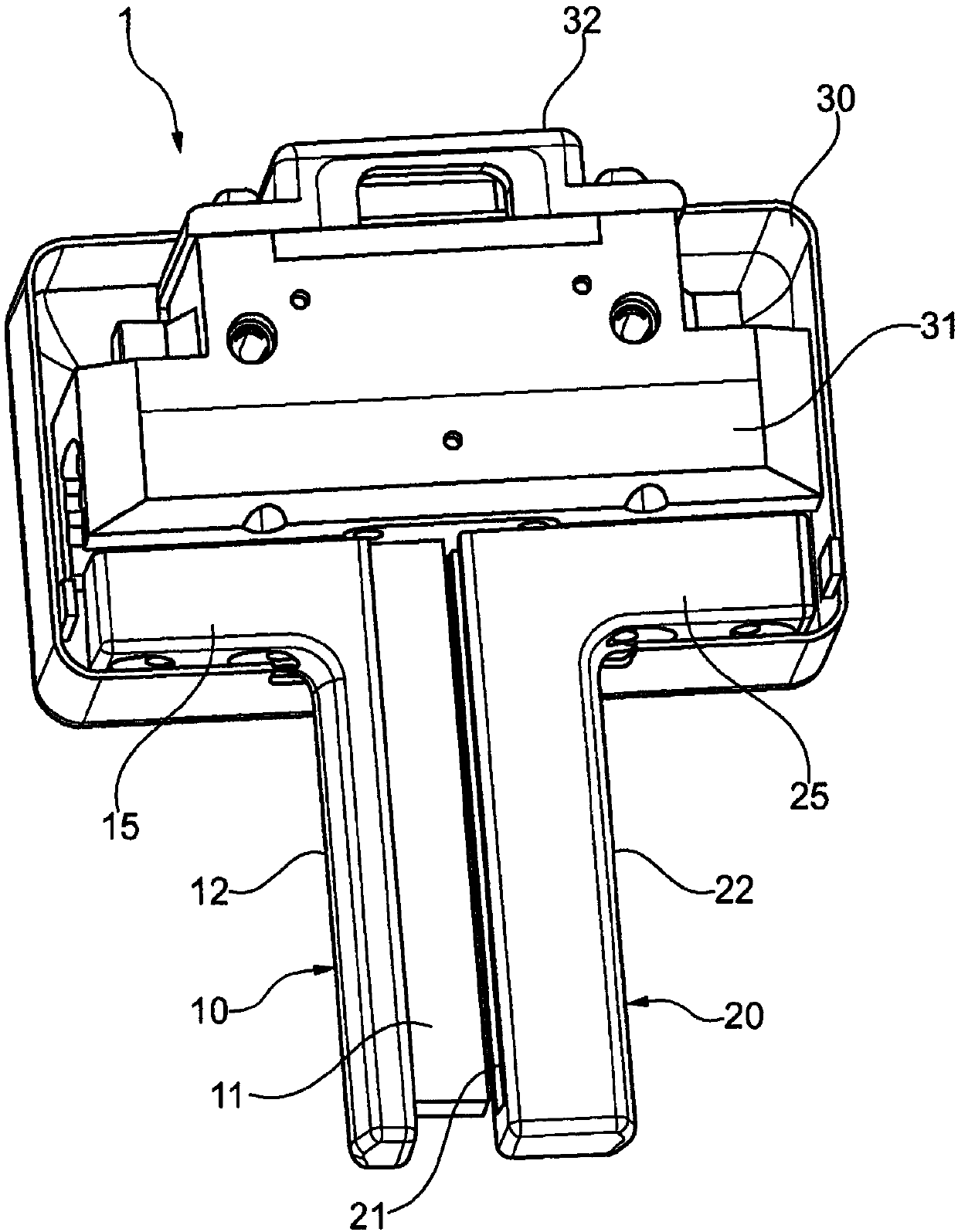

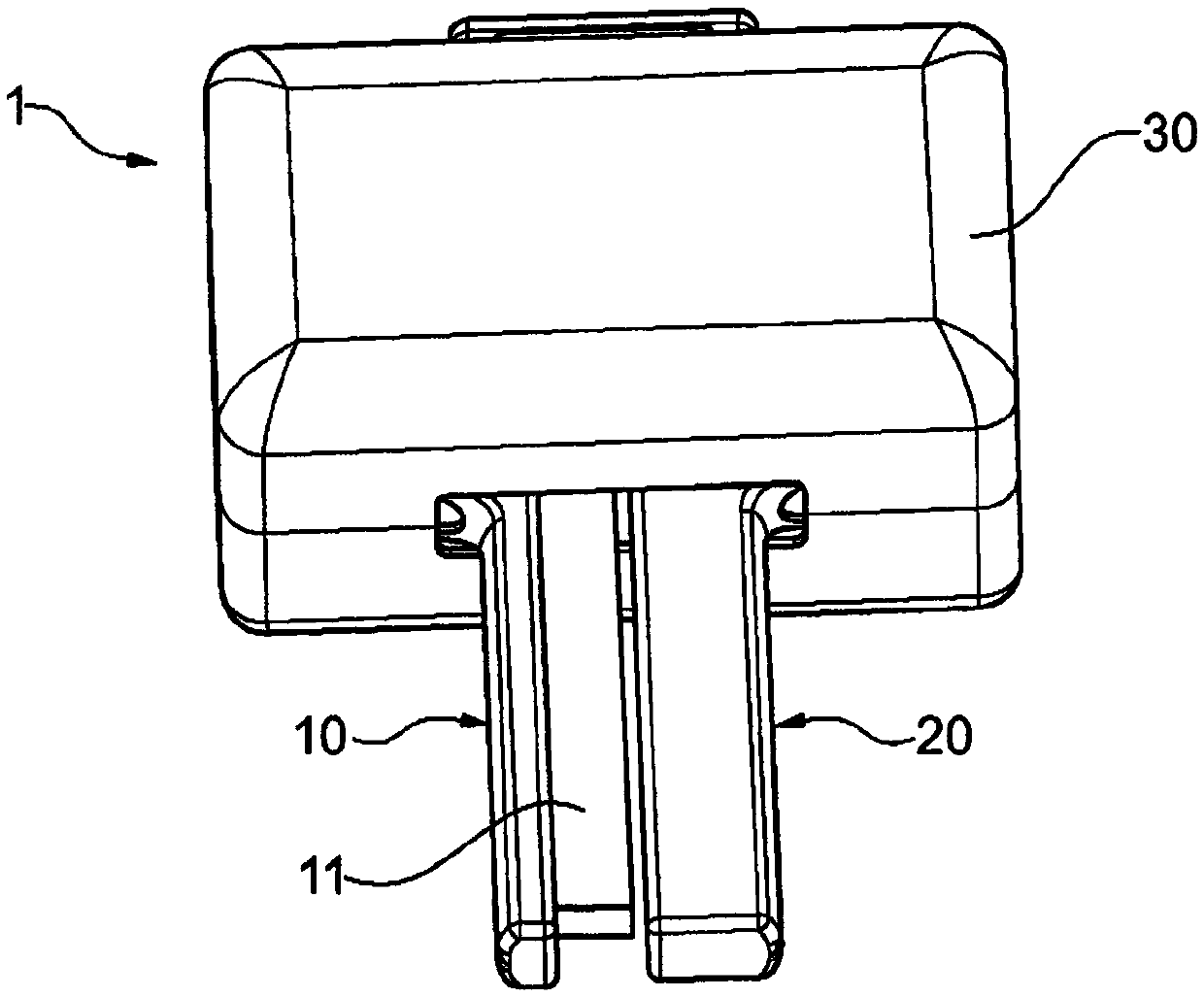

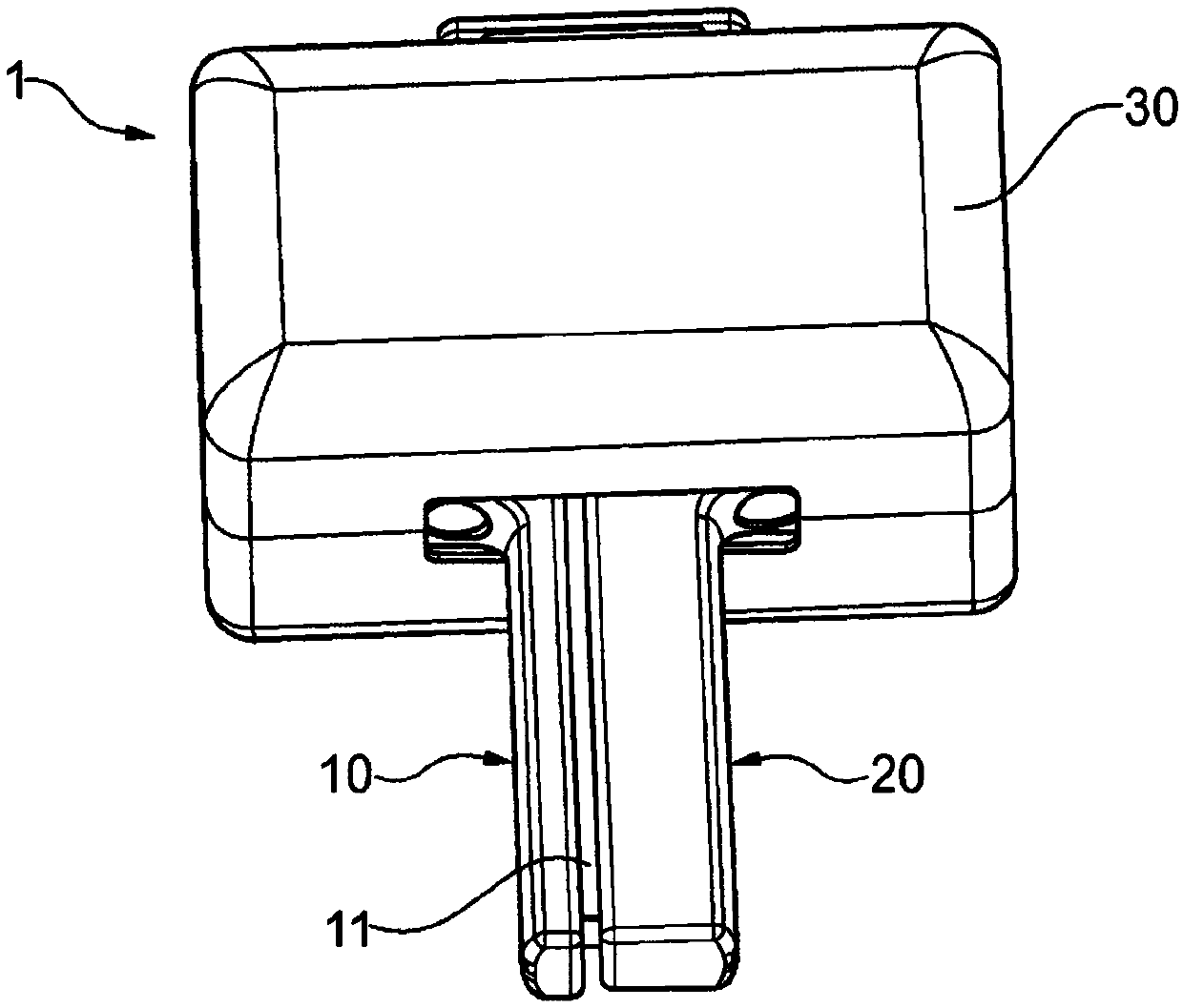

[0019] figure 1 A three-dimensional view of the gripping device 1 according to the invention is schematically shown with the housing 30 partially opened. The gripping device 1 has two jaws 10 and 20 which are arranged to be movable relative to each other. As can be seen by a person skilled in the art, the gripping device 1 shown in the figure is a bifurcated gripping device, which is designed to be introduced into the inner space or hollow space of the workpiece and pass through The movement of the two gripper jaws 10 and 20 away from each other, or divergence, grips the workpiece. The two jaws are rod-shaped and run parallel. The first jaw 10 has a tenon projection 11 on the side facing the second jaw 20 . The tenon projection 11 is formed integrally with the clamping jaw 10 , but can also be a separate part which is arranged or fixed on the first clamping jaw 10 . The second clamping jaw 20 has a groove on the side facing the first clamping jaw, which groove is designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com