A packaging unit having improved sealing, and a method for forming such a packaging unit

A resealing and area technology, applied in the field of packaging units of hygienic goods, can solve the problems of damage to the packaging unit manufacturing, inaccurate folding, edge part influence, etc., and achieve the effect of tightly discarded packaging, easy to unfold and seal, and convenient to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

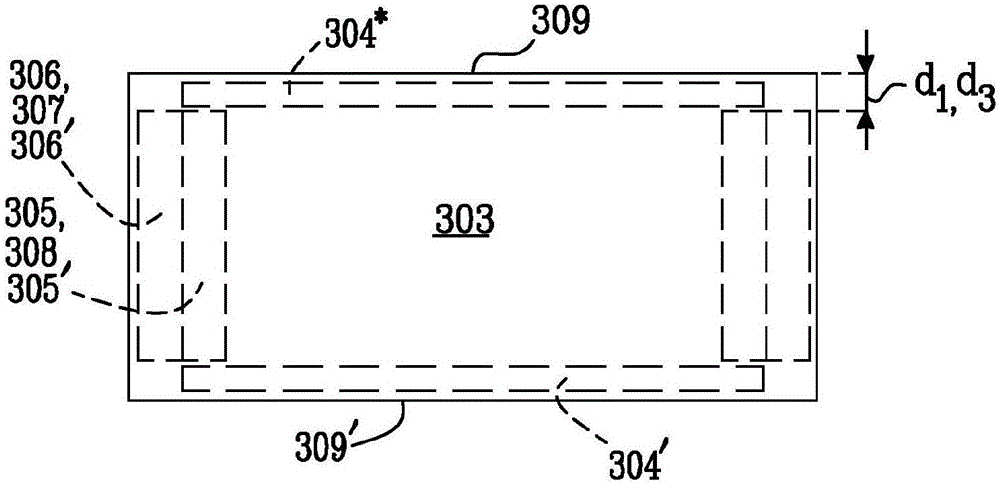

[0063]Figure 1 depicts a packaging unit 1 for hygiene articles according to the invention. The packaging unit is formed from a sheet of material having an inner surface 2 and an outer surface 3 , the inner surface comprising an edge zone 4 comprising inner edge portions 5 , 8 and outer edge portions 6 , 7 . The packaging unit 1 also comprises a first transverse edge zone 4 ′ and a second transverse edge zone 4 ″. The sheet has a first folding axis 9 , wherein the folding axis divides the sheet into a first region 10 and a second region 11 . As shown in Figure 1, the outer edge portion 6 of the edge zone 4 of the first region 10 is provided with a resealable adhesive 12, thereby forming a first adhesive zone 13, while the edge zone 4 of the first region 10 The inner edge portion 5 is free of adhesive. As shown in Figure 1, the first adhesive zone 13 is arranged at a distance d1 from the first folding axis 9, which provides sufficient space for the folding tool to be positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com