A three-level bidirectional charging and discharging circuit

A charge-discharge circuit, three-level technology, applied to battery circuit devices, circuit devices, collectors, etc., can solve problems such as unfavorable system stability, small adjustment range of charge-discharge voltage, large single-phase output ripple, etc., to achieve High engineering application value, realizing the frequency multiplication function of the inductor current, and reducing the effect of ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

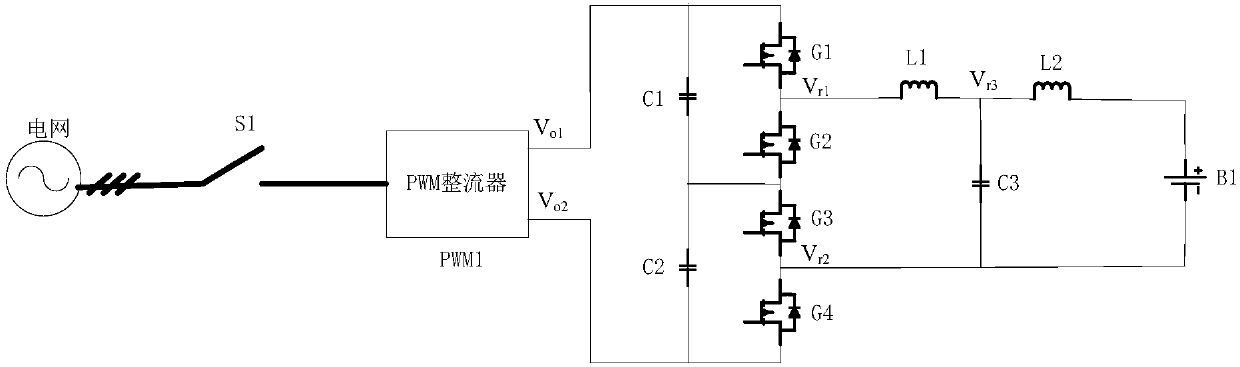

[0066] In a preferred embodiment of the present invention, the filter circuit includes:

[0067] A first inductor L1, connected to the first reference node V r1 and a third reference node V r3 between;

[0068] A second inductor L2, connected to the third reference node V r3 and battery voltage terminal B1;

[0069] A first filter capacitor C3, connected to the third reference node V r3 and battery voltage terminal B1.

[0070] The first inductor L1 is connected to V r1 and V r3 Between, the second inductor L2 is connected to V r3 Between and battery B1, the first filter capacitor C3 is connected to the third reference node V r3 and battery B1.

[0071] In a preferred embodiment of the present invention, the three-level bidirectional charging and discharging circuit further includes: an air switch S1 connected between the grid voltage terminal and the PWM rectifier PWM1 for protecting the charging and discharging circuit.

[0072] The present invention adopts a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com