Thrust fault construction physical simulation experiment device

An experimental device and physical simulation technology, applied to teaching models, educational tools, instruments, etc., can solve the problems of unsafe manipulation, poor visibility, and high cost of use, and achieve the effects of safe and simple operation, easy observation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the objectives, technical solutions, and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, and not to limit the present invention.

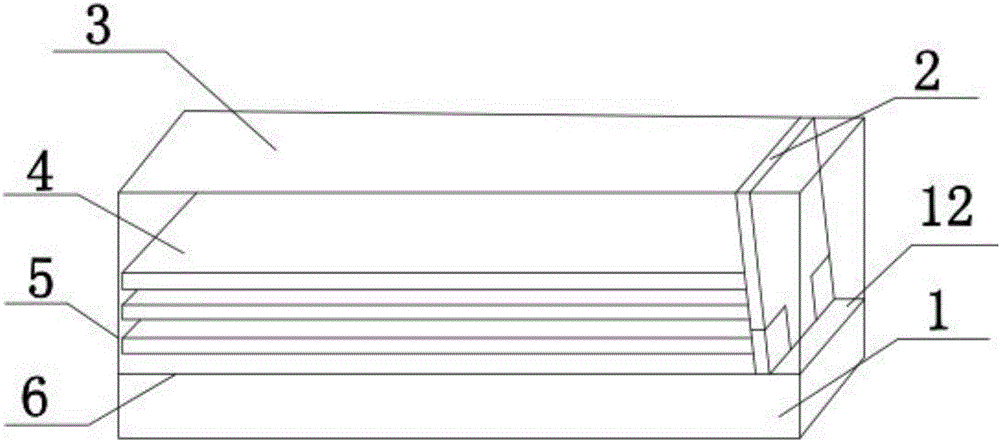

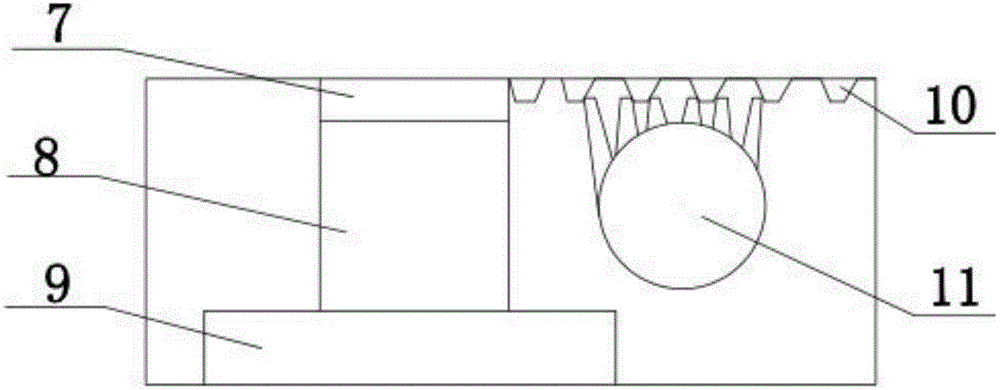

[0014] See Figure 1 to Figure 2 , This specific implementation adopts the following technical solutions: it includes the experimental device table 1, the movable plate 2, the stratum model 4, the fixed plate 5, the fixed plate 6, the push rod 7, the screw 8, the motor 9, the linear rack 10, the rotation Gear 11, movable plate fixing seat 12.

[0015] A fixed plate 5 is fixedly arranged on both sides of the experimental device table 1, a fixed plate 6 is fixedly arranged on the top of the experimental device table 1, one end of the fixed plate 6 is provided with a circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com