Magneto-rheological damper performance testing device

A magnetorheological shock absorber and testing device technology, which can be applied to measurement devices, machine/structural component testing, vehicle suspension/shock-absorbing mechanism testing, etc. Test requirements and other issues, to achieve the diversification of test functions, to meet the effect of adjustable incentives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

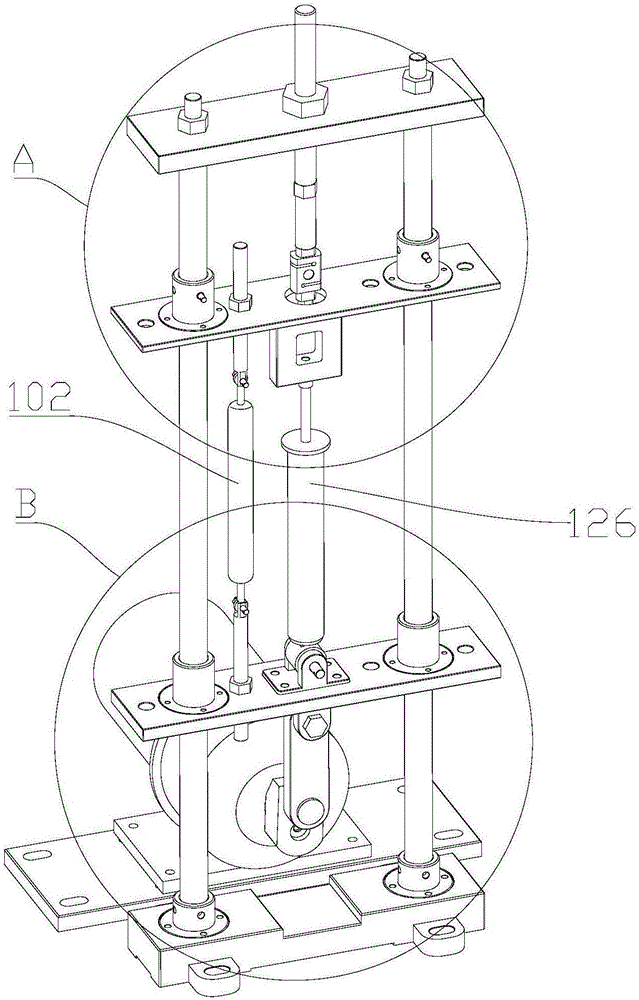

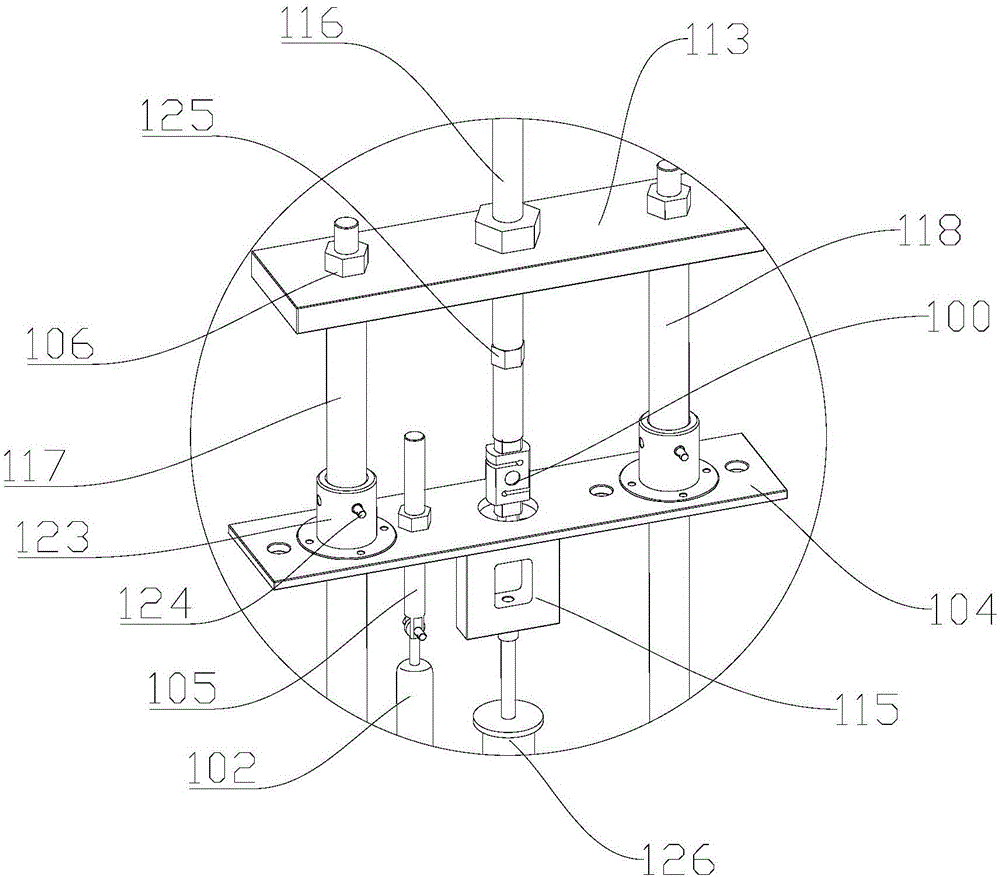

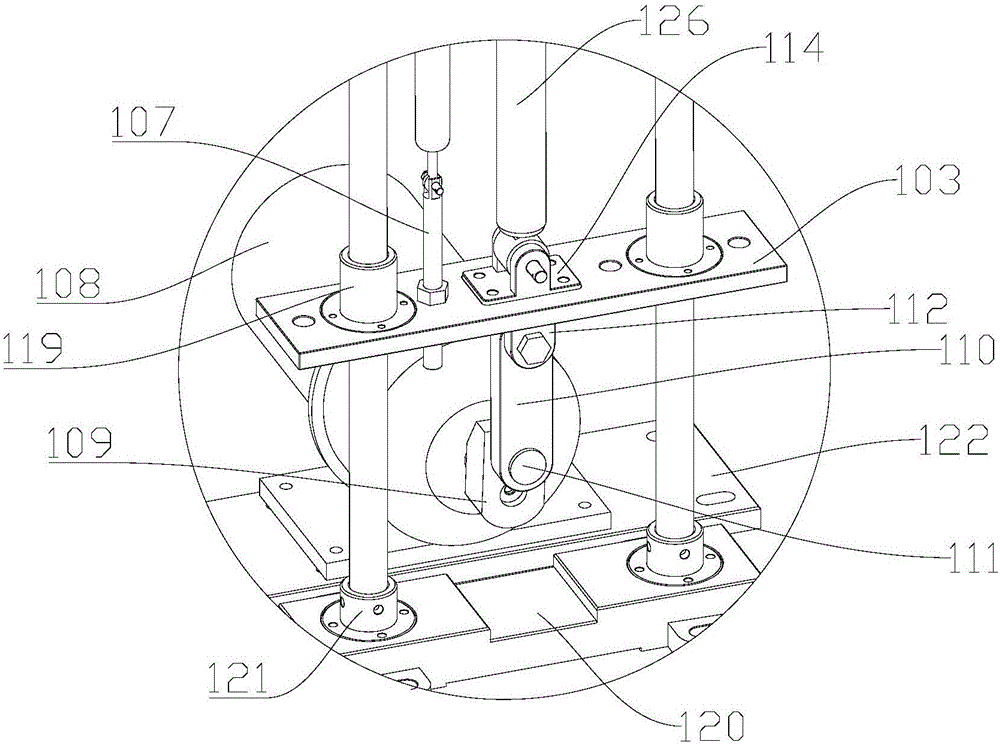

[0041] see Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention provides a performance test device for a magneto-rheological shock absorber, which is used for the performance test of a magneto-rheological shock absorber for automobiles, including a power unit, a guide mechanism, a force sensor 100 and a displacement sensor 102 The power unit is used to make the magnetorheological shock absorber 126 to be tested reciprocate along the guiding direction of the guide mechanism; the force sensor 100 is used to detect the magnetorheological shock absorber to be tested when the The generated damping force information, that is, the information of the magnitude of the damping force produced by the magneto-rheological shock absorber to be tested; the displacement sensor 102 is used to detect the reciprocating motion of the magnetorheological shock absorber to be tested, The displacement information of the shock absorber, that is, the information of the displacement chan...

Embodiment 2

[0060] The magnetorheological shock absorber performance testing device in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment. .

[0061]In this embodiment, the MRA performance testing device also includes an acceleration sensor, which is used to detect the acceleration information of the MRA to be tested when the MRA reciprocates, that is to say, The acceleration of the magneto-rheological shock absorber to be tested is measured in real time. Specifically, the acceleration sensor is electrically connected to the computer, and the computing mechanism is also used to receive the acceleration information of the magnetorheological shock absorber to be tested sent by the acceleration sensor in real time. The acceleration sensor is installed on the reciprocating guide plate 103 to detect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com