Spent fuel assembly damage detection apparatus

A damage detection and detection device technology, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, etc., to avoid external leakage, avoid damage to the instrument, and realize the effect of online real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0018] The invention mainly establishes a closed-loop gas on-line measurement and sampling circuit, evaluates whether the spent fuel is damaged through the online measurement and sampling analysis method, and provides personnel safety assurance basis and corresponding technical support for unloading operations.

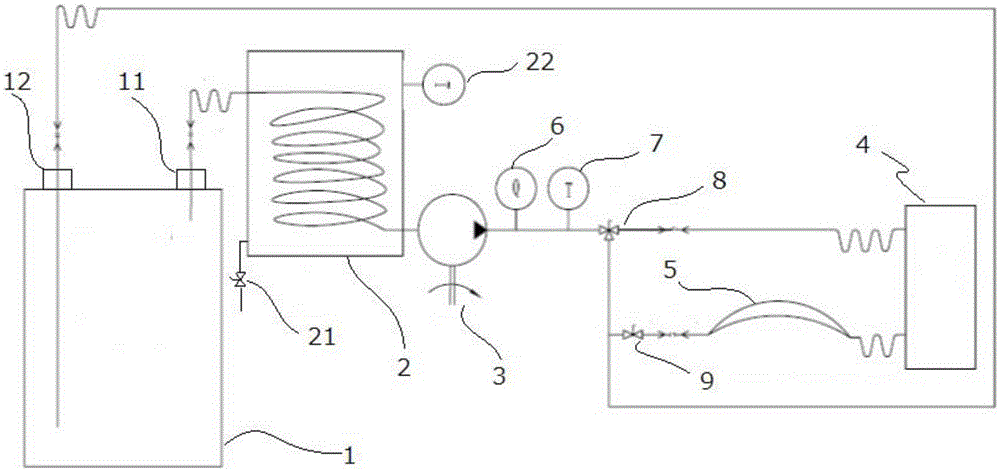

[0019] refer to figure 1 , is a structural schematic diagram of the spent fuel assembly damage detection device of the present invention.

[0020] The spent fuel assembly damage detection device of the present invention is used to monitor in real time whether the spent fuel assembly in the spent fuel transfer container 1 is damaged. The transfer container 1 is provided with an output interface 11 and a recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com