Extension-type gas-solid high-speed two-phase flow efficient heating equipment

A heating equipment and casing type technology, which is applied in the field of casing type gas-solid high-speed two-phase flow high-efficiency heating equipment, can solve the problems of accumulation and deflagration, increase the heat exchange area, enhance the heat exchange effect, and solve the problem of wear-resistant life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

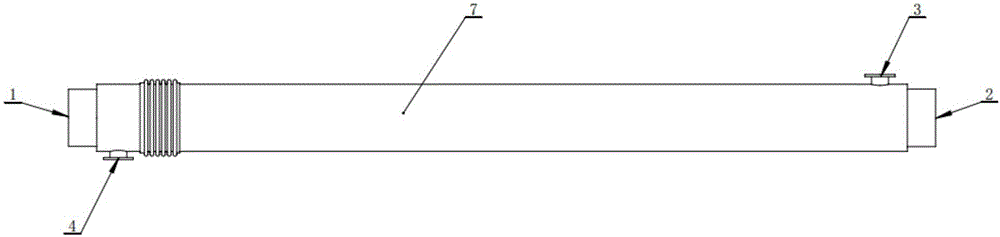

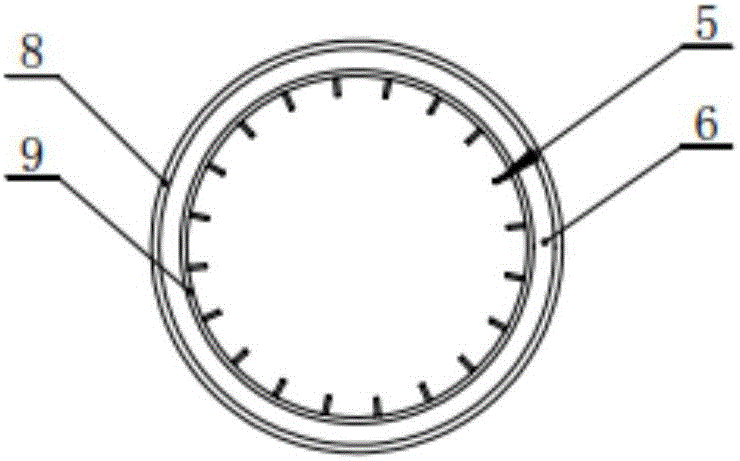

[0020] Such as figure 1 , 2 As shown, the tube bundle type gas-solid high-speed two-phase flow high-efficiency heating equipment of the present invention includes: a heating pipe body 7, a gas-solid mixture circulation inlet pipeline 1, a gas-solid mixture circulation outlet pipeline 2; a heat source pipeline inlet 3, and a drain pipeline outlet 4 , Rib plate 5. Among them, a gas-solid mixture circulation pipe 1 is provided in the heating pipe body 7; a heat source pipe inlet 3 is provided at the outer top of the heating pipe body 7; a drain pipe outlet 4 is provided at the outer end of the heating pipe body 6. An outer sleeve 8 is arranged outside the gas-solid mixture pipeline; the area between the outer sleeve 8 and the inner tube 9 is used as the heat source circulation pipeline 6, and the steam circulates along the annular passage of the sleeve. Ribs 5 arranged at circumferential intervals are arranged on the inside or outside of the original gas-solid mixture pipeline....

specific Embodiment approach

[0022] The specific embodiment that heater of the present invention is used for gas-solid mixture heating is:

[0023] The gas-solid mixture enters the gas-solid mixture channel provided with the rib plate 5 from the gas-solid mixture circulation inlet pipe 1; at the same time, the heat source enters the heating pipe body 7 through the heat source pipe inlet 3; the heat source circulates along the heat source circulation pipe 6 casings, and The gas-solid mixture undergoes countercurrent heat exchange; after the temperature of the gas-solid mixture increases, it enters other connecting pipes through the outlet pipe 2 of the gas-solid mixture, and the heat source that completes the heat exchange releases heat to form water (or steam, air), and then exits through the water pipe 4 collected for other use.

[0024] The heater of the present invention can be applied in any heat exchange environment with different media. For example: gas-solid mixture heating device for coal-fired p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com