A sintering cooling machine and its dynamic sealing equipment

A technology of sintering cooling machine and dynamic sealing, which is applied in the direction of lighting and heating equipment, furnaces, furnace materials, etc., which can solve the problems of poor sealing effect and achieve the effects of reduced air leakage rate, good wear resistance and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

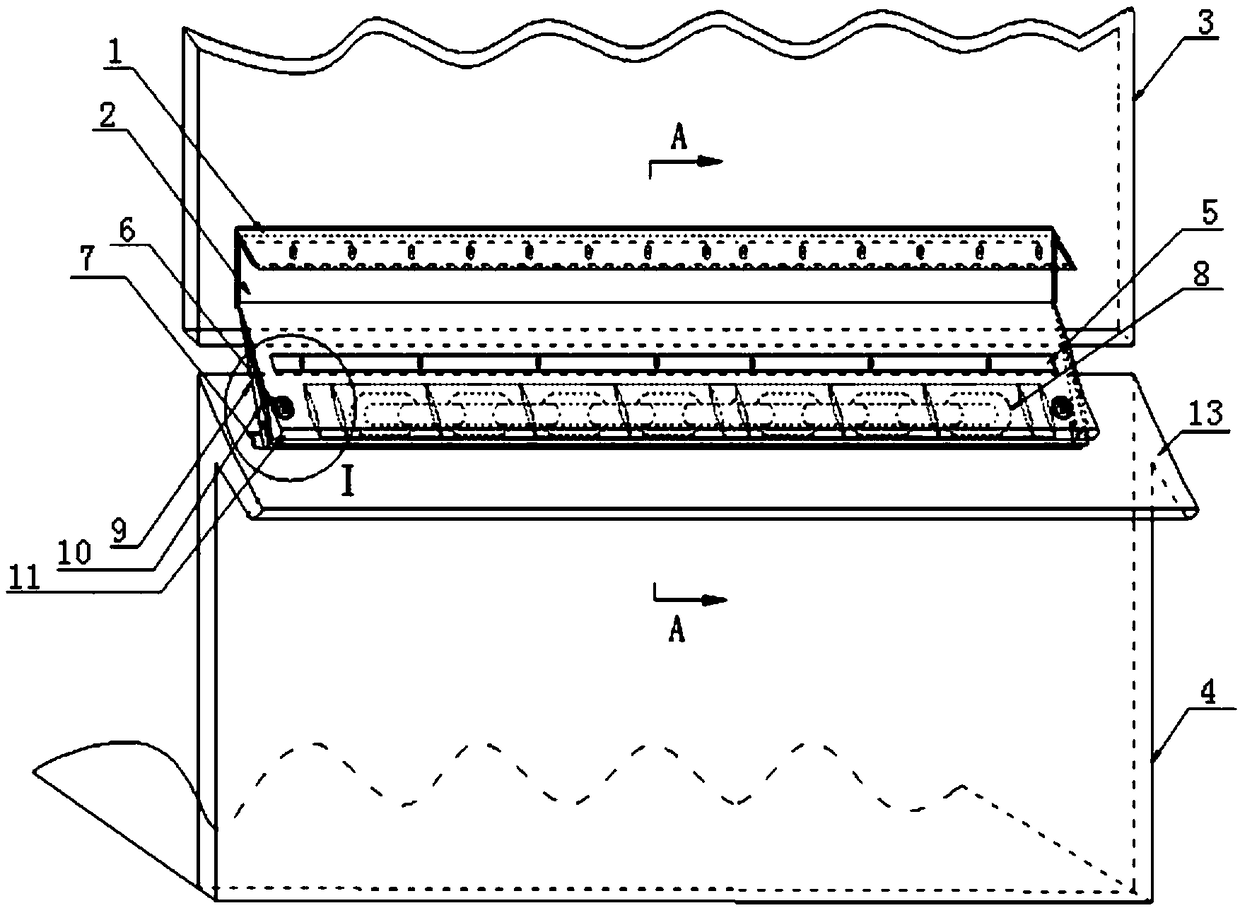

[0064] The seal between the cooling bed trolley and the smoke hood in the traditional sintering cooler is made of a fiberboard with a certain strength, and one side of the fiberboard is fixed on the fume hood, and the dynamic friction between the fiberboard and the top of the cooling bed trolley is used. Sealing is achieved, but the sealing effect of this line sealing method is relatively poor, and due to the large temperature difference between the two sides of the fiberboard, after periodic thermal expansion and contraction, the strength of the fiberboard itself is attenuated, and the deformed fiberboard exerts pressure on the top of the cooling bed trolley. The gap between the two is getting bigger and bigger, and the air leakage rate is gradually increasing; moreover, due to the wear of the track, there is a misalignment between adjacent cooling bed trolleys on the track, which will make the cooling bed trolley Scratching with the fiberboard during exercise will cause the f...

Embodiment 2

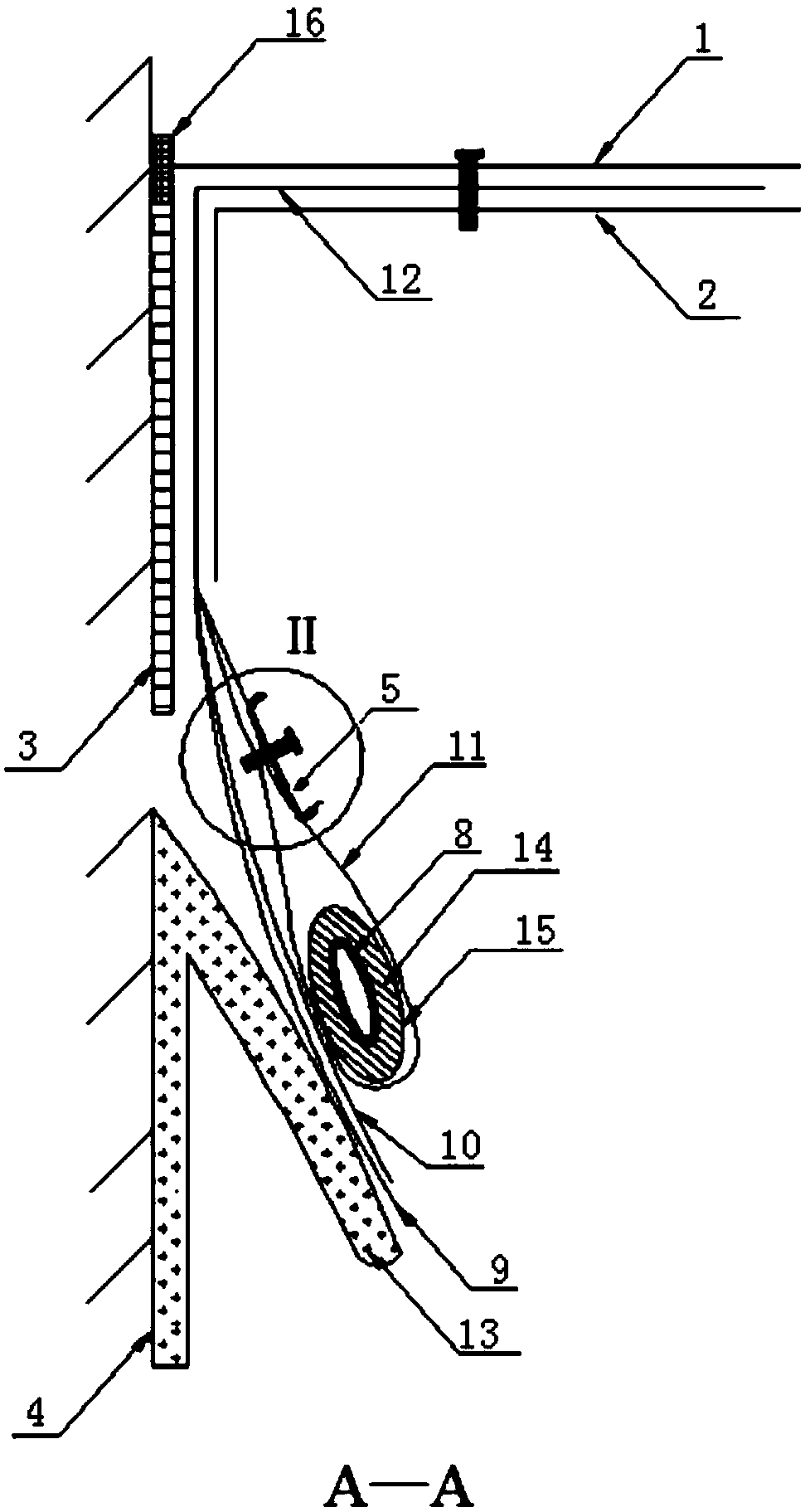

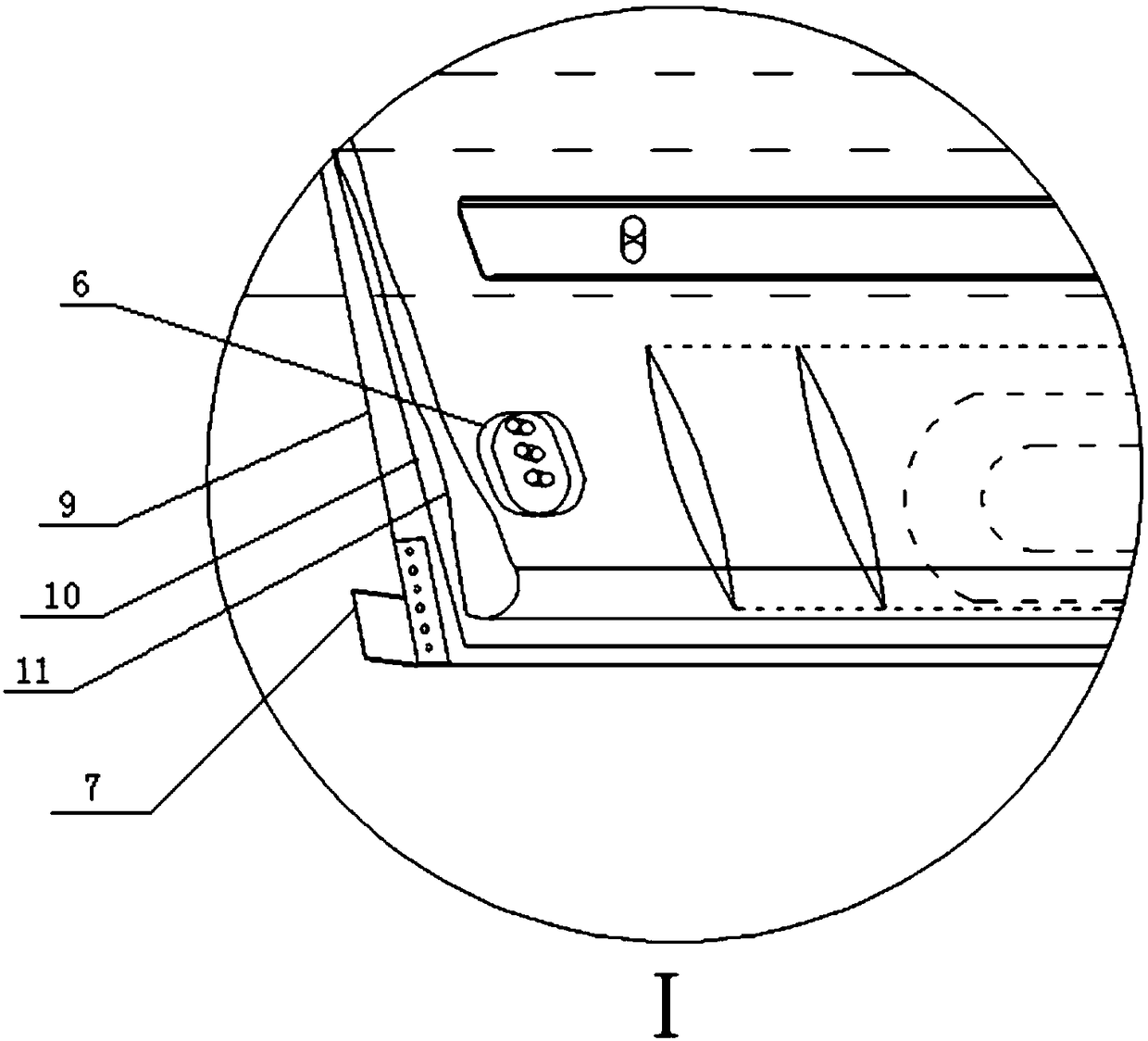

[0068] refer to Figure 1~4 , the sintered cooling machine of the present embodiment, its structure is basically the same as embodiment 1, further:

[0069] Wherein, the dynamic sealing device includes: a heat-resistant sealing layer 12 whose upper end is fixed on the side of the hood 3 , and a counterweight 8 is connected to the lower end of the heat-resistant sealing layer 12 .

[0070] In this embodiment, the heat-resistant sealing layer 12 can play a good sealing role, and can withstand higher ambient temperature during work; the counterweight 8 is connected to the lower end of the heat-resistant sealing layer 12, so that the heat-resistant sealing layer 12 The lower end is compressed on the cooling trolley 4 under the gravity of the counterweight 8 to realize the compression and sealing effect.

Embodiment 3

[0072] refer to Figure 1~4 , the sintered cooling machine of the present embodiment, its structure is basically the same as that of embodiment 2, further:

[0073] The heat-resistant sealing layer 12 is made of flexible materials; the upper part of the cooling trolley 4 is provided with an inclined plate 13 inclined downward, and the lower end of the heat-resistant sealing layer 12 is pressed against the surface of the inclined plate 13 under the gravity of the counterweight 8 .

[0074] In this embodiment, the upper part of the cooling trolley 4 is provided with an inclined plate 13 inclined downward, and the lower end of the heat-resistant sealing layer 12 is pressed against the surface of the inclined plate 13 under the gravity of the counterweight 8, wherein the inclined plate 13 is inclined downward. The inclined plate 13 can be arranged on the inner side of the upper part of the cooling trolley 4, and can also be arranged on the outer side of the upper part of the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com