Modular frame down lamp

A downlight and frame technology, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve problems such as rotten edges or stains of ceiling installation holes, safety accidents, and inability to replace the light source part alone. , to achieve the effect of reducing procurement costs and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

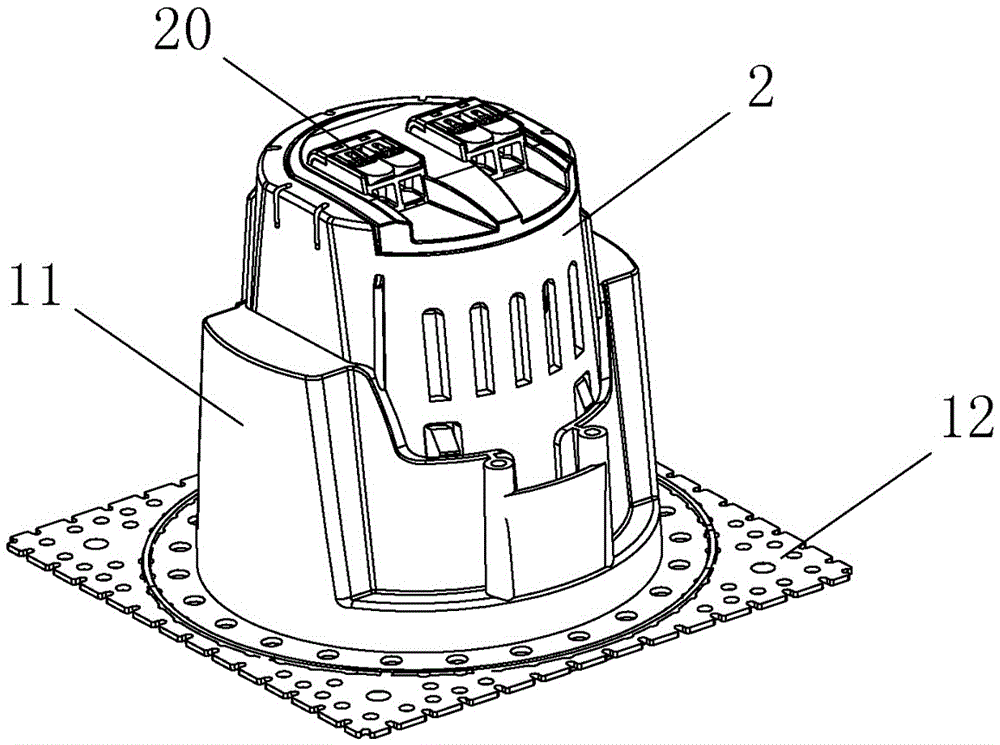

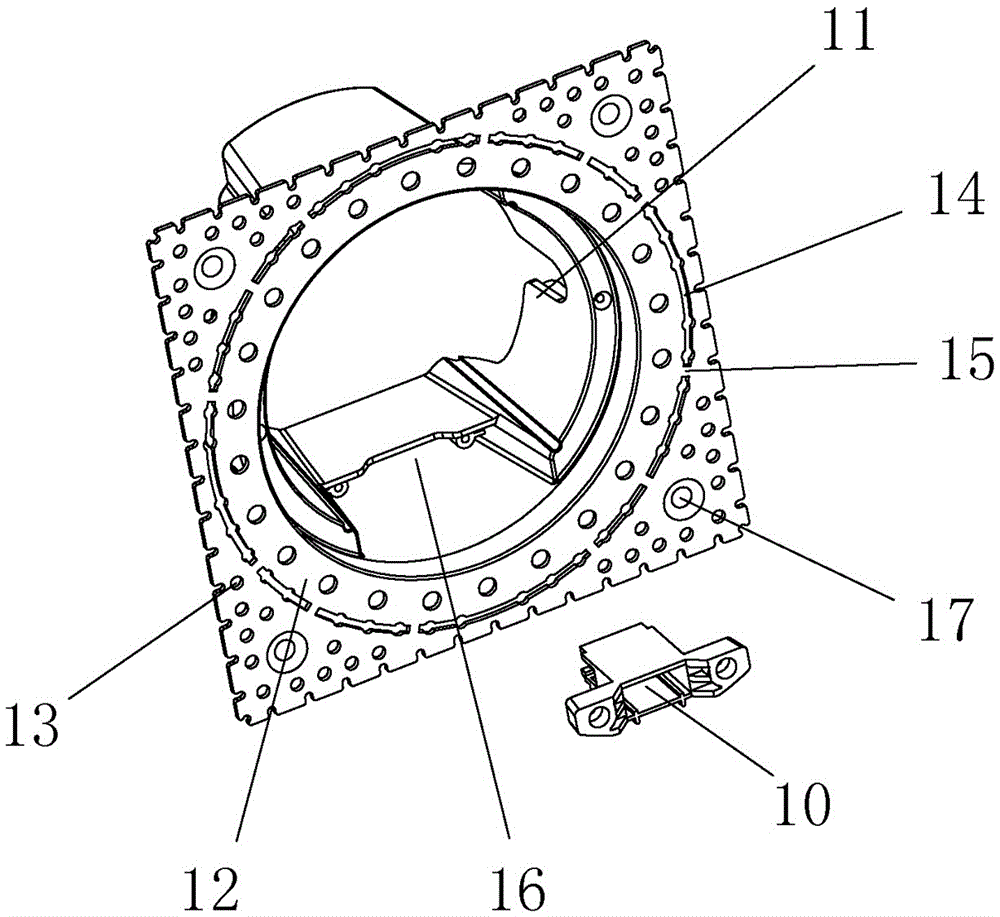

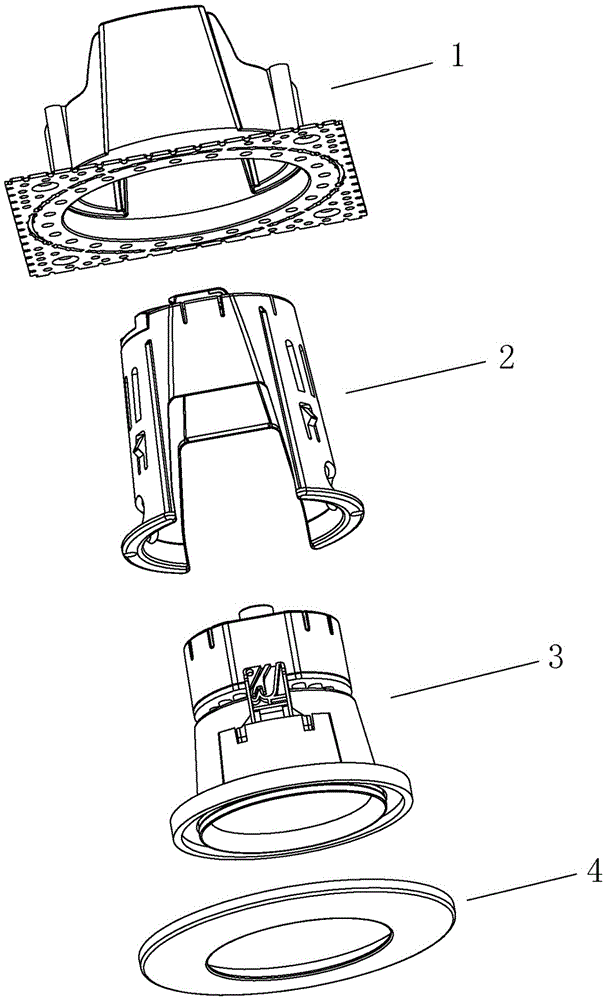

[0025] refer to Figure 1 to Figure 7 , a modular downlight with a frame, which is composed of four parts: an embedded part 1, an intermediate part 2, a lamp body 3 and a cover 4; the intermediate part 2 is installed in the embedded part 1; the The lamp body 3 is installed in the middle part 2, and a connecting structure is provided between the lamp body 3 and the middle part 2 or the embedded part 1; the surface cover 4 is movably connected to the middle part 2 or the lamp body 3 at the lower end.

[0026] In this embodiment, the fastening structure includes a clamping seat 10 provided on the embedded part 1 and a clamping joint 30 provided on the lamp body 3, and the inner wall of the embedded part 1 is provided with A cavity 16 with an opening downward, the clamping seat 10 is fixed in the cavity 16 by screws. The clamping joint 30 and the clamping seat 10 form a rebound self-locking structure. The rebound self-locking structure is also called a rebound self-locking devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com