Automobile gear box integrating clutch function and gear shifting function

A technology of automobile gearbox and clutch, which is applied to components with teeth, transmission parts, gear transmissions, etc., can solve the problems of complex gearbox structure, slow power transmission, power waste, etc., and achieve simple structure and power transmission. Fast, dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

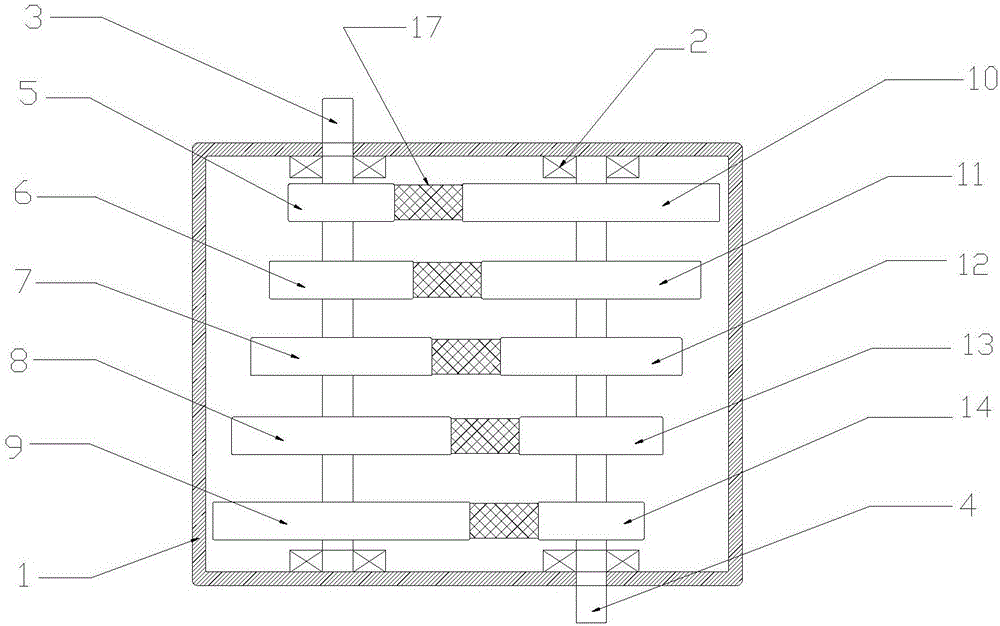

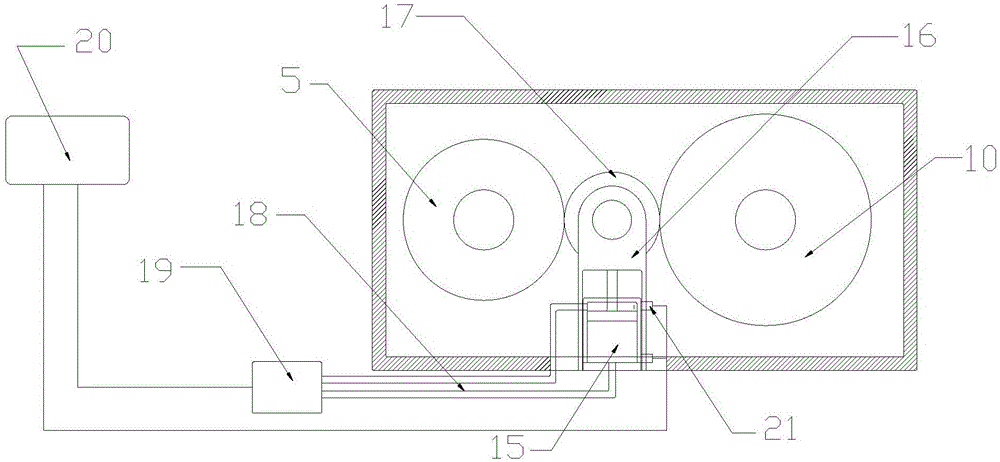

[0019] Such as Figure 1-2 As shown, the present invention provides a kind of automobile gearbox that integrates clutch and shifting functions, including gearbox body 1, input shaft 3, output shaft 4, connecting gear 17 and hydraulic reversing valve 19, gearbox body 1 is A hollow rectangular box, the side wall of the gearbox body 1 is inlaid with two pairs of bearings 2 through the installation holes, the inner walls of the two pairs of bearings 2 are respectively fitted with the input shaft 3 and the output shaft 4, and the input shaft 3 and the output shaft 4 are parallel Setting, the middle part of the input shaft 3 runs through and connects with the first driving gear 5, the second driving gear 6, the third driving gear 7, the fourth driving gear 8, the fifth driving gear 9 and the middle part of the output shaft 4 in sequence respectively. The first driven gear 10, the second driven gear 11, the third driven gear 12, the fourth driven gear 13 and the fifth driven gear 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com