Novel two-stroke internal combustion engine

A two-stroke internal combustion engine, a new type of technology, applied in the direction of combustion engines, mechanical equipment, machines/engines, etc., can solve the problems of not reaching, reducing the air volume, affecting the efficiency of intake and exhaust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed structural description of specific embodiments of the present invention given in conjunction with the accompanying drawings is to facilitate the understanding of the technical solutions of the present invention, and should not be regarded as limiting the scope of protection of the claims of the present invention.

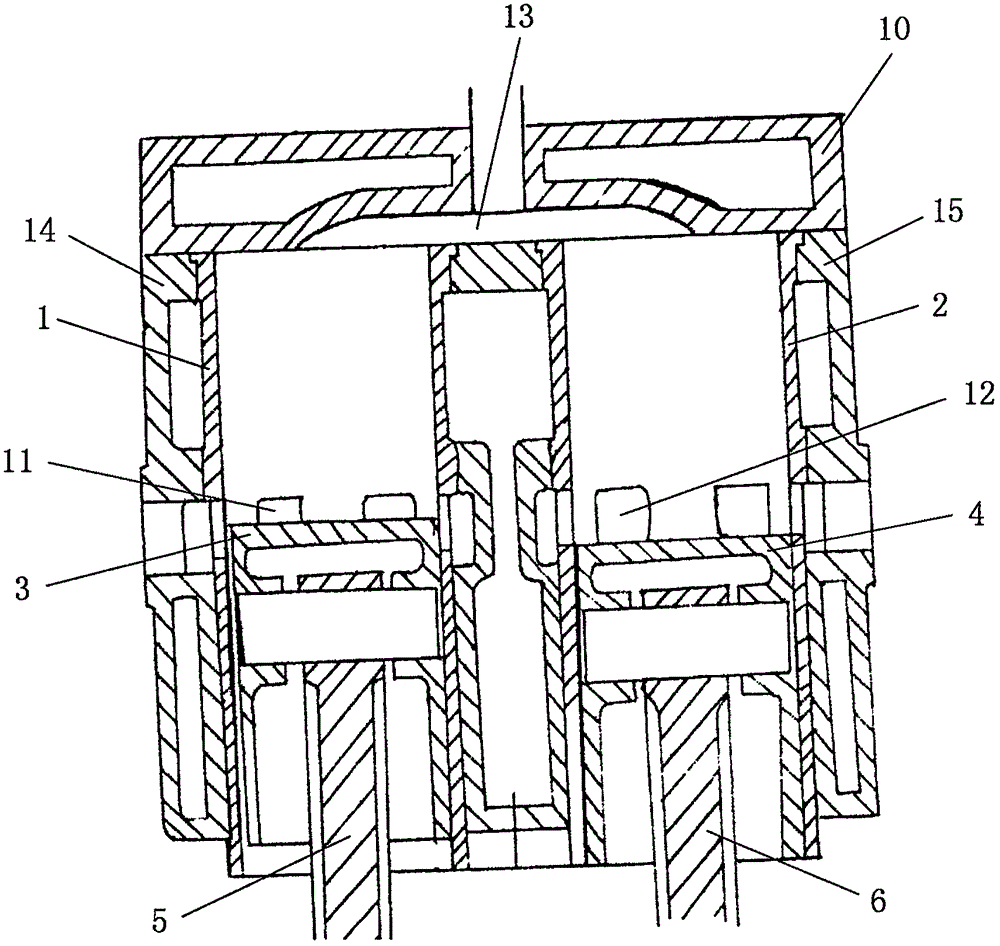

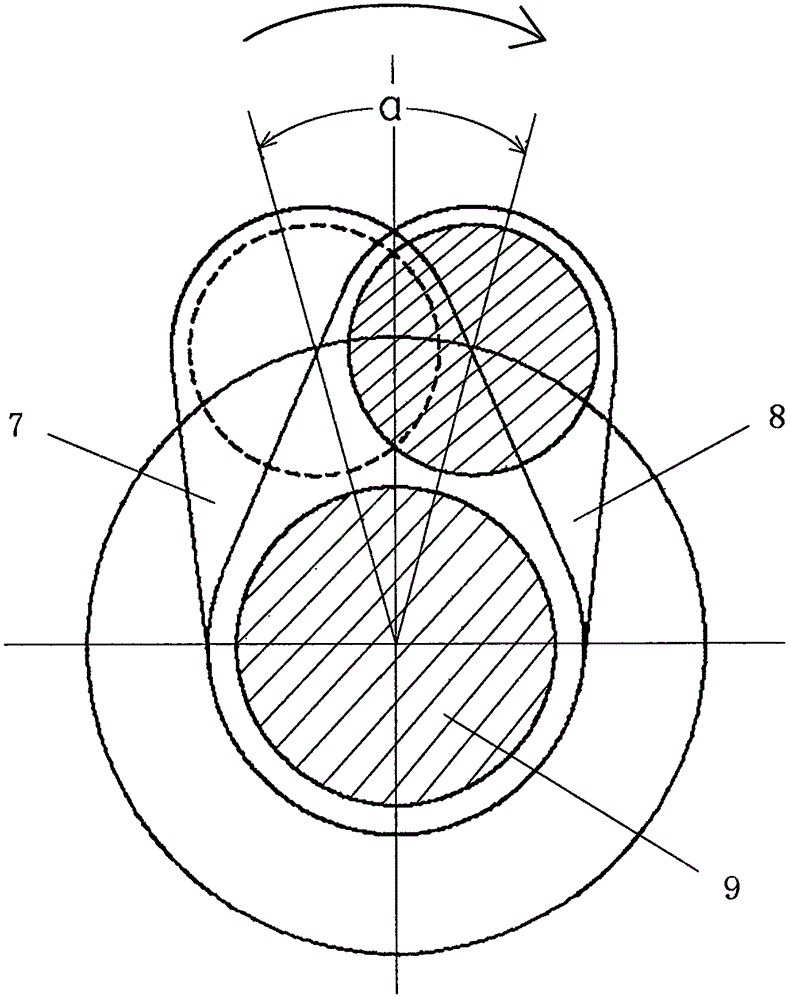

[0021] See Figure 1 ~ Figure 2 , the specific embodiment of the present invention is as follows: intake cylinder 1 and exhaust cylinder 2 are provided with intake cylinder piston 3 and exhaust cylinder piston 4 respectively, and advance, exhaust cylinder piston (3,4) all sequentially enters, exhaust cylinder connecting rod ( 5, 6), intake and exhaust cylinder crank throws (7, 8) are connected with crankshaft 9, and the up and down reciprocating motion of intake and exhaust cylinder pistons (3, 4) drives the rotation of crankshaft 9 through the above-mentioned connection structure to output power. 1. One end of the exhaust cylinder (1, 2) is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com