Post-fracture flow-back tracking detecting method for horizontal well

A detection method and horizontal well technology, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc. It can solve the problem of inability to determine whether the liquid at target point B returns to the wellbore or not, and whether the tracer concentration is accurate Filling, insufficient stability and reliability, etc., to achieve the effect of stable detection results, strong practicability, and reliable filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

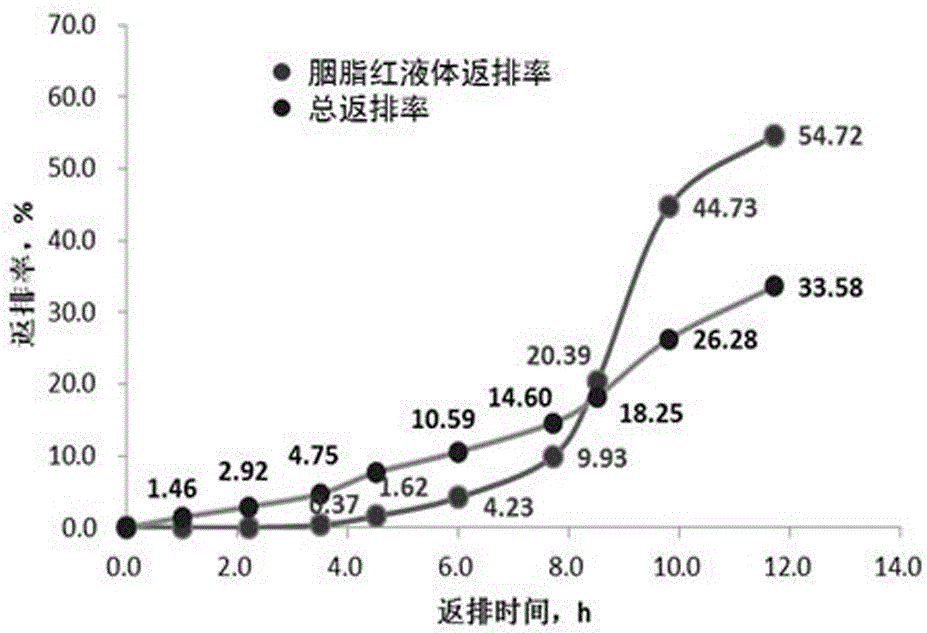

[0034] The present invention is a flowback tracing detection method after fracturing of a horizontal well, which comprises the following sequential steps:

[0035] Step 1. Adding a tracer in the fracturing fluid required for construction, the tracer is a carmine tracer, so as to obtain the tracer fracturing fluid; the filling operation includes the following specific steps:

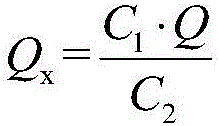

[0036] 1). According to the designed carmine concentration and tracer fracturing fluid volume, calculate the required carmine weight according to the following formula: W=C x ×V 1 ; In the formula, W is carmine weight; C x is the carmine concentration; V 1 is the tracer fracturing fluid volume;

[0037] 2). According to the tracer fracturing fluid volume and the designed construction displacement, the pumping time of the tracer fracturing fluid is calculated according to the following formula: T=V 1 / Q 1 ; where T is the pumping time of tracer fracturing fluid; Q 1 is the construction displacement; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com