Segmented oil-stabilizing water-controlling method and device

A water control device and oil stabilizing technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems of easily polluted formations, oil layer pollution, and inaccurate control of injection positions, etc., to achieve segmental plugging Good effect, suppression of water cone breakthrough, high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

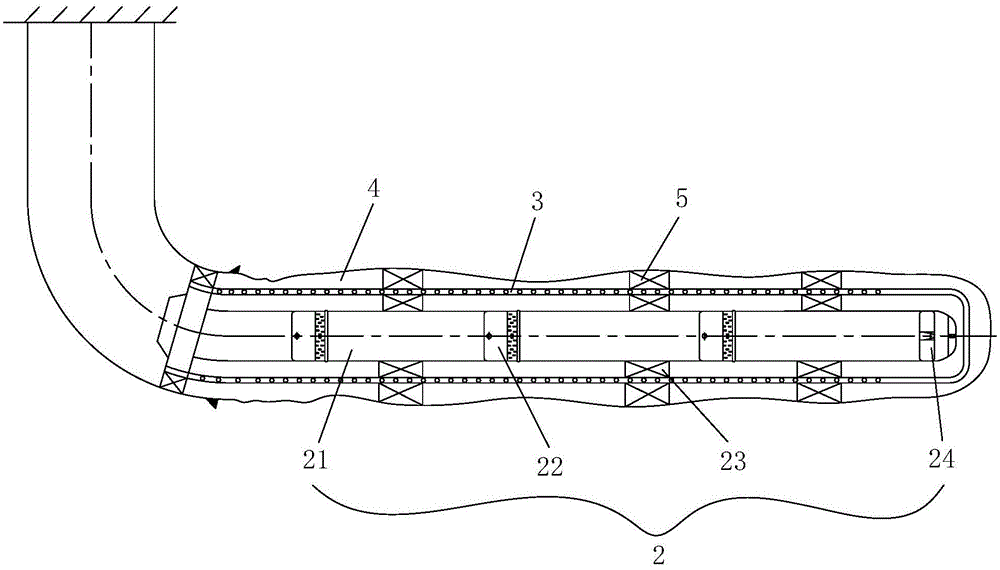

[0052] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

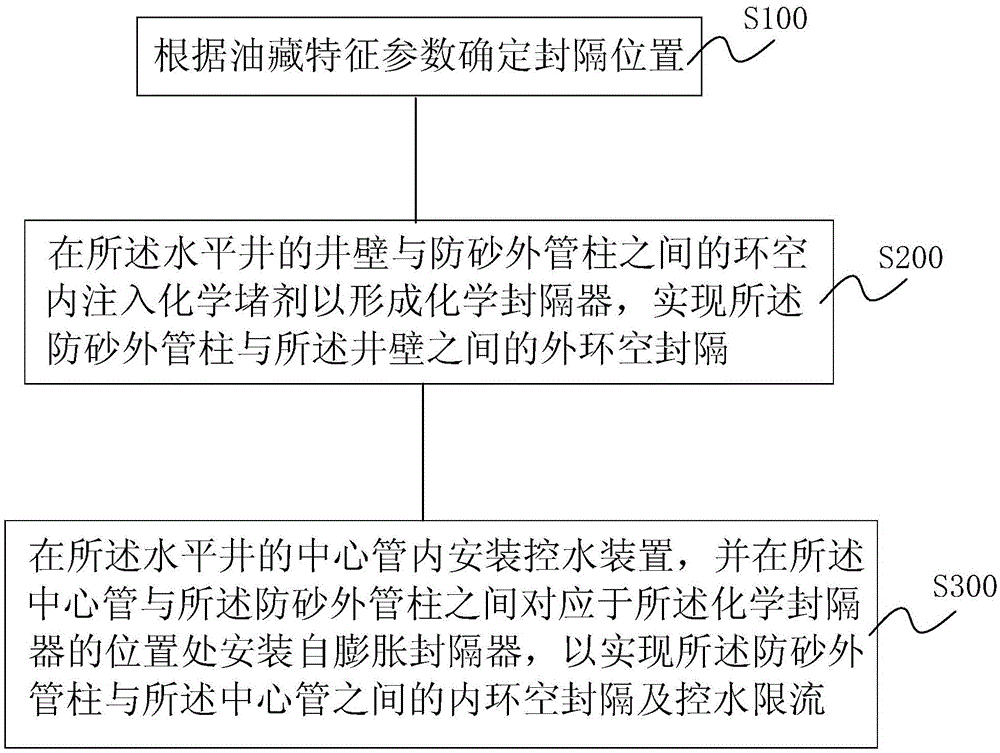

[0053] see figure 1 , figure 1 It is a method flow chart of an embodiment of the present invention. The segmental oil stabilization and water control method of the present invention is used for the plugging of multiple layers of the horizontal well 4, adaptive water control and oil stabilization production, and adopts segmental oil stabilization and water control strings 2 and chemical plugging agent injection pipes Column 1 realizes the three processes of chemical plugging agent annulus isolation, formation chemical plugging, and composite adaptive device water control, so as to solve the problem of oil well production under various well conditions such as the current oil well is not run into the packer or the layering cannot meet the requirements. According to the geological conditions of the reservoir, the three methods c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com