Automatic conveying device for oil pipe rod applied to workover treatment and conveying method of automatic conveying device

A technology of automatic conveying device and conveying device, which is applied to drill pipes, drill pipes, casings, etc., can solve the problems of no thread protection device, large force on the pipe rod grab arm, and damage to the tubing rod thread, so as to reduce labor costs. The effect of handling, saving resources and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

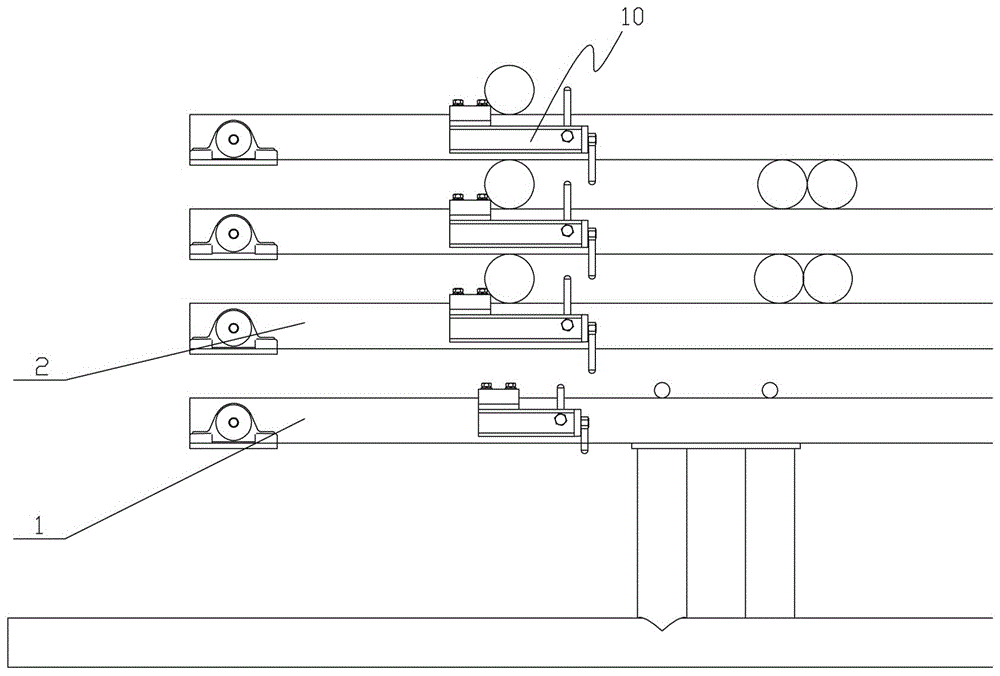

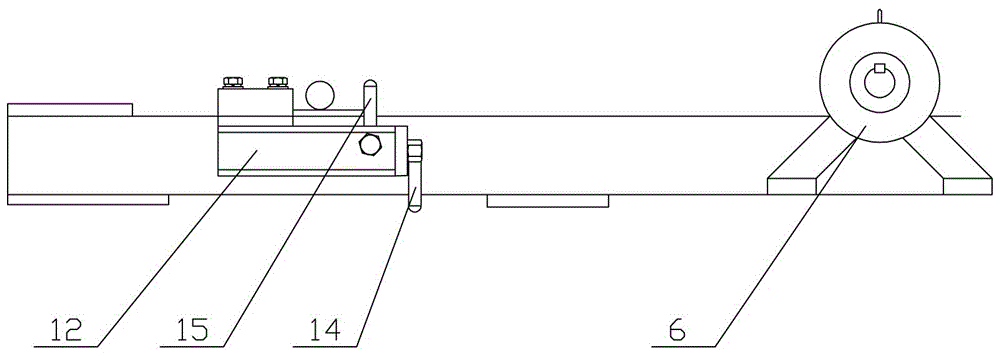

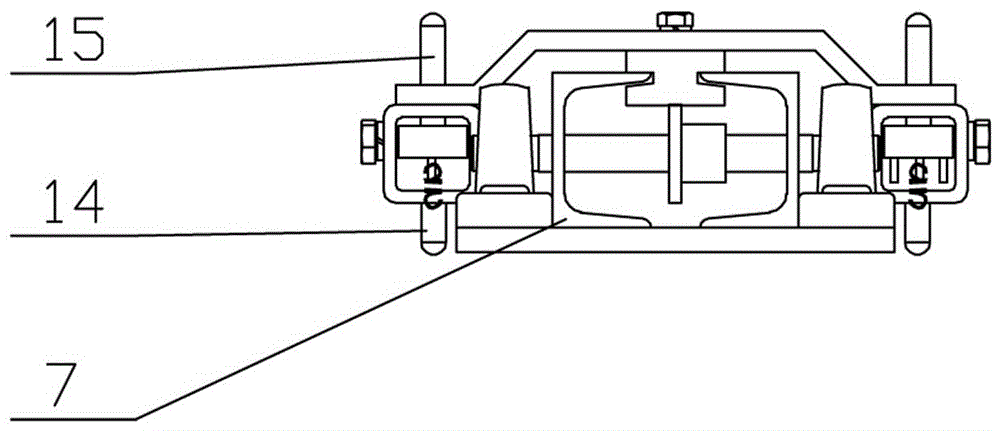

[0042] Such as Figure 1 to Figure 3 As shown, an automatic delivery device for tubing rods in workover operations, the delivery device is composed of 2 to 4 groups of parallel pipe bridges, the ends of the pipe bridges are connected to the lifting mechanism 20, and the pipe bridges are composed of four layers of spacers. It is characterized in that: at least two groups of pipe bridges are provided with a motor 6 at the end of each spacer, the spacer is connected to the pushing device 10 through a slideway 7, and a connecting plate 12 with a boss is provided above the pushing device 10, The connection plate 12 is connected with the motor 6 through a transmission device; the two ends of the connection plate 12 are respectively provided with upwardly protruding pipe-taking stop pins 15, and the pipe-taking stop pins 15 are limited by elastic devices to rotate only toward the direction of the connecting plate boss ; The end of the moving direction of the push-out device 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com