Ground fire hydrant

A technology of fire hydrant and hydrant body, applied in fire rescue and other directions, can solve the problems of inconvenient disassembly and replacement of valve body, difficult maintenance and high maintenance cost, and achieve the effect of avoiding a large amount of water leakage, low maintenance cost and good collision resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

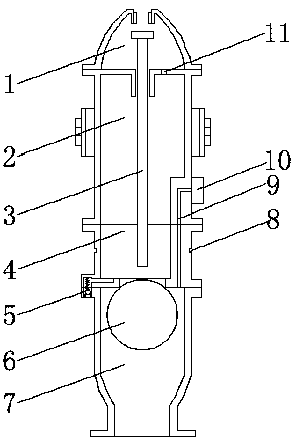

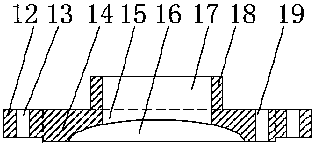

[0026] Such as figure 1 Shown, the above-ground fire hydrant of the present invention comprises a plug body, a bumper joint, a valve body, a water pressure gauge, a ball float valve, and a tappet. An exhaust valve is arranged on the top of the plug body, which is used to discharge the gas inhaled after the underground water is cut off. The anti-collision joint is arranged between the bolt body and the valve body, and the top and bottom ends of the anti-collision joint are respectively connected to the bottom of the bolt body and the top of the valve body through flanges. The outer wall of the anti-collision section is provided with a ring breaking groove, which is an annular groove, and surrounds the outer wall of the anti-collision section once or twice or more times, so that the thickness of the side wall of the anti-collision section at the ring bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com