Paving material and environment-friendly easy-drainage porous pavement structure prepared through paving material

A technology for paving materials and permeable pavement, which is applied to the coagulation pavement, pavement details, roads and other directions of on-site paving, which can solve the problems such as the inability to give full play to the superior performance of the drainage pavement, the small drainage area of the drainage pipe, and the untimely drainage. To achieve the effect of good drainage, improve overall strength, avoid damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

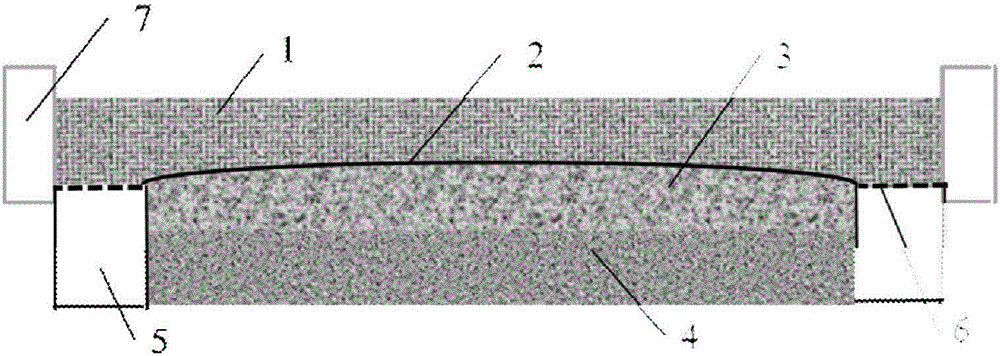

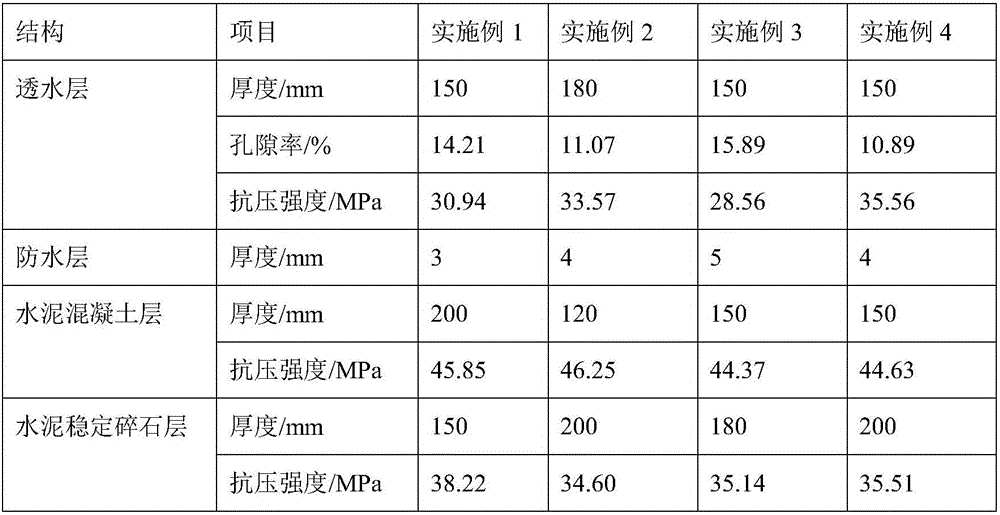

[0026] The pavement structure includes a water-permeable layer 1, a waterproof layer 2, a cement concrete layer 3, a cement-stabilized gravel layer 4, a drainage culvert 5, a steel mesh 6 and a curb 7; the cement-stabilized gravel layer 4 is paved with the same width The cement concrete layer 3 is also provided with a drain culvert 5 with a reinforced mesh 6 on both sides; the cement concrete layer 3 is convex arched, and its two ends are flush with the reinforced mesh 6; the permeable layer 1 is laid on the cement concrete layer 3 and above the underdrain 5; the waterproof layer 2 is coated along the upper surface of the cement concrete layer 3 and the bottom and side walls of the underdrain 5; both sides of the permeable layer 1 are curbs 7. Permeable layer 1 has a porosity of 14.21% and a thickness of 150mm; waterproof layer 2 has a thickness of 3mm and is membrane-like and impermeable; cement concrete layer 3 has a thickness of 200mm; cement stabilized gravel layer 4 has a ...

Embodiment 2

[0029] The pavement structure includes a water-permeable layer 1, a waterproof layer 2, a cement concrete layer 3, a cement-stabilized gravel layer 4, a drainage culvert 5, a steel mesh 6 and a curb 7; the cement-stabilized gravel layer 4 is paved with the same width The cement concrete layer 3 is also provided with a drain culvert 5 with a reinforced mesh 6 on both sides; the cement concrete layer 3 is convex arched, and its two ends are flush with the reinforced mesh 6; the permeable layer 1 is laid on the cement concrete layer 3 and above the underdrain 5; the waterproof layer 2 is coated along the upper surface of the cement concrete layer 3 and the bottom and side walls of the underdrain 5; both sides of the permeable layer 1 are curbs 7. Permeable layer 1 has a porosity of 11.07% and a thickness of 180mm; waterproof layer 2 has a thickness of 4mm and is membrane-like and impermeable; cement concrete layer 3 has a thickness of 120mm; cement stabilized gravel layer 4 has a ...

Embodiment 3

[0032] The pavement structure includes a water-permeable layer 1, a waterproof layer 2, a cement concrete layer 3, a cement-stabilized gravel layer 4, a drainage culvert 5, a steel mesh 6 and a curb 7; the cement-stabilized gravel layer 4 is paved with the same width The cement concrete layer 3 is also provided with a drain culvert 5 with a reinforced mesh 6 on both sides; the cement concrete layer 3 is convex arched, and its two ends are flush with the reinforced mesh 6; the permeable layer 1 is laid on the cement concrete layer 3 and above the underdrain 5; the waterproof layer 2 is coated along the upper surface of the cement concrete layer 3 and the bottom and side walls of the underdrain 5; both sides of the permeable layer 1 are curbs 7. Permeable layer 1 has a porosity of 15.89% and a thickness of 150mm; waterproof layer 2 has a thickness of 5mm and is membrane-like and impermeable; cement concrete layer 3 has a thickness of 150mm; cement stabilized gravel layer 4 has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com