Flame retardant rubber windshield rubber part and preparation method thereof

A flame-retardant rubber and windshield technology, which is applied in the field of rubber materials, can solve the problems of iron windshields such as loud noise, wind, sand, rain and snow, and loose contact, so as to achieve tight contact, prevent dust, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

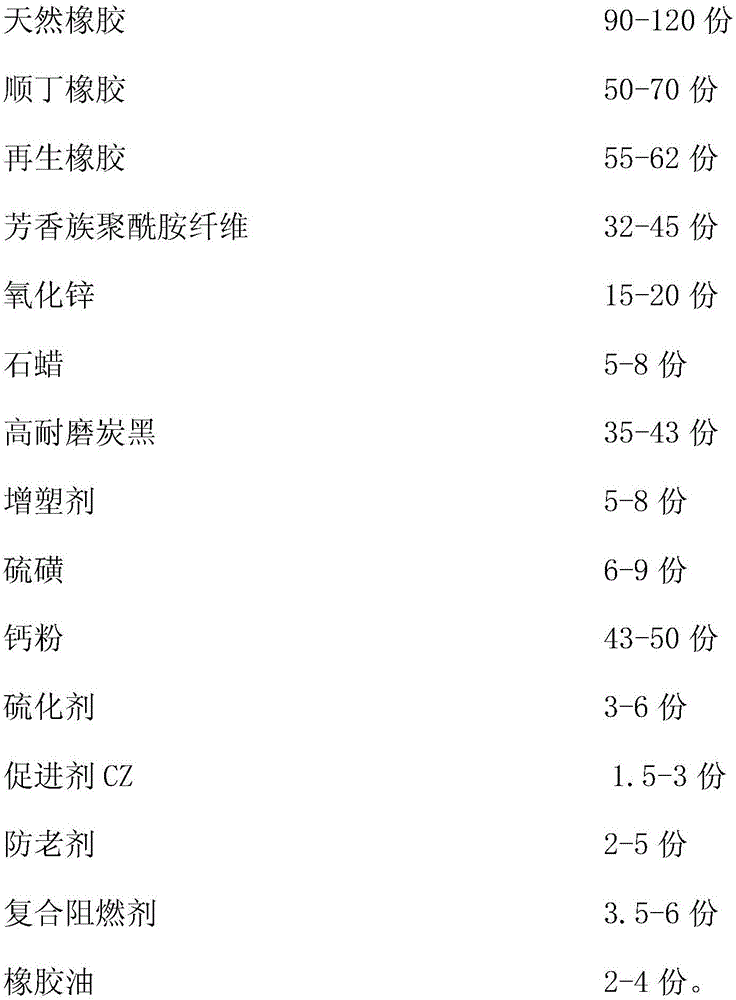

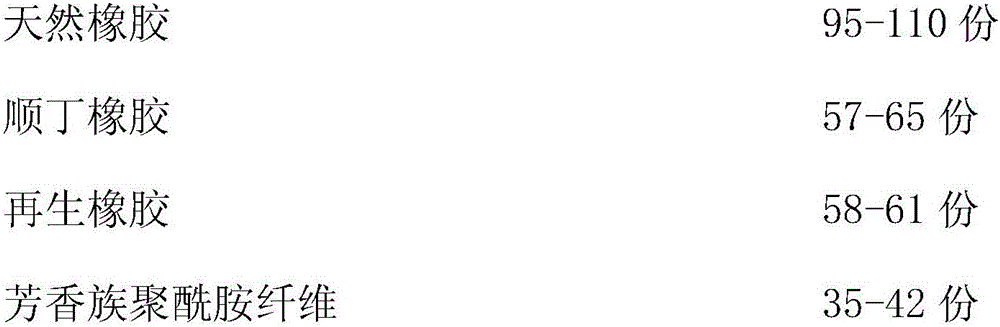

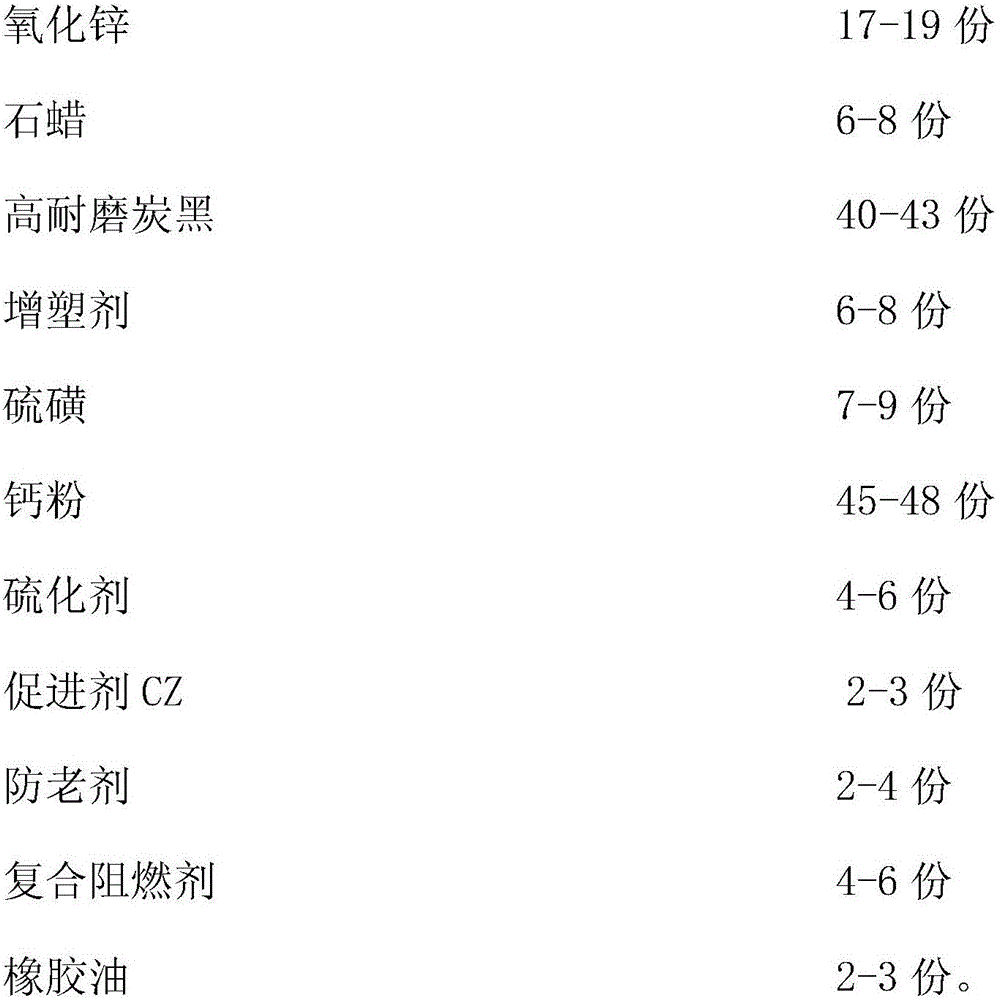

Method used

Image

Examples

Embodiment 1

[0024] A flame-retardant rubber windshield rubber part, which is composed of the following raw materials in parts by weight: 90 parts of natural rubber, 50 parts of butadiene rubber, 55 parts of regenerated rubber, 32 parts of aromatic polyamide fiber, 15 parts of zinc oxide, 5 parts of paraffin, 35 parts of high wear-resistant carbon black, 5 parts of plasticizer, 6 parts of sulfur, 43 parts of calcium powder, 3 parts of vulcanizing agent, 1.5 parts of accelerator CZ, 2 parts of antioxidant, 3.5 parts of composite flame retardant, 2 parts of rubber oil ; Among them, the composite flame retardant is composed of magnesium hydroxide, diatomaceous earth, zinc borate and melamine, and its weight ratio is 2:2:1:4.

[0025] A preparation method of a flame-retardant rubber windshield rubber part, comprising the following steps:

[0026] (1) take each raw material of corresponding weight part respectively;

[0027] (2) Add natural rubber, butadiene rubber and regenerated rubber to th...

Embodiment 2

[0031] A flame-retardant rubber windshield rubber part, which is composed of the following raw materials in parts by weight: 120 parts of natural rubber, 70 parts of butadiene rubber, 62 parts of regenerated rubber, 45 parts of aromatic polyamide fiber, 20 parts of zinc oxide, 8 parts of paraffin, 43 parts of high wear-resistant carbon black, 8 parts of plasticizer, 9 parts of sulfur, 50 parts of calcium powder, 6 parts of vulcanizing agent, 3 parts of accelerator CZ, 5 parts of anti-aging agent, 6 parts of composite flame retardant, 4 parts of rubber oil ; Among them, the composite flame retardant is composed of magnesium hydroxide, diatomaceous earth, zinc borate and melamine, and its weight ratio is 2:2:1:4.

[0032] A preparation method of a flame-retardant rubber windshield rubber part, comprising the following steps:

[0033] (1) take each raw material of corresponding weight part respectively;

[0034] (2) Add natural rubber, butadiene rubber and regenerated rubber to ...

Embodiment 3

[0038] A flame-retardant rubber windshield rubber part, which is composed of the following raw materials in parts by weight: 100 parts of natural rubber, 60 parts of butadiene rubber, 58 parts of regenerated rubber, 40 parts of aromatic polyamide fiber, 18 parts of zinc oxide, 6 parts of paraffin, 38 parts of high wear-resistant carbon black, 6 parts of plasticizer, 7 parts of sulfur, 46 parts of calcium powder, 5 parts of vulcanizing agent, 2 parts of accelerator CZ, 3 parts of antioxidant, 5 parts of composite flame retardant, 3 parts of rubber oil ; Among them, the composite flame retardant is composed of magnesium hydroxide, diatomaceous earth, zinc borate and melamine, and its weight ratio is 2:2:1:4.

[0039] A preparation method of a flame-retardant rubber windshield rubber part, comprising the following steps:

[0040] (1) take each raw material of corresponding weight part respectively;

[0041] (2) Add natural rubber, butadiene rubber and regenerated rubber into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com