Automatic glutinous rice cake granulating device

A kind of glutinous rice cake, automatic technology, applied in the direction of metal processing, etc., can solve the problems of low cutting efficiency and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

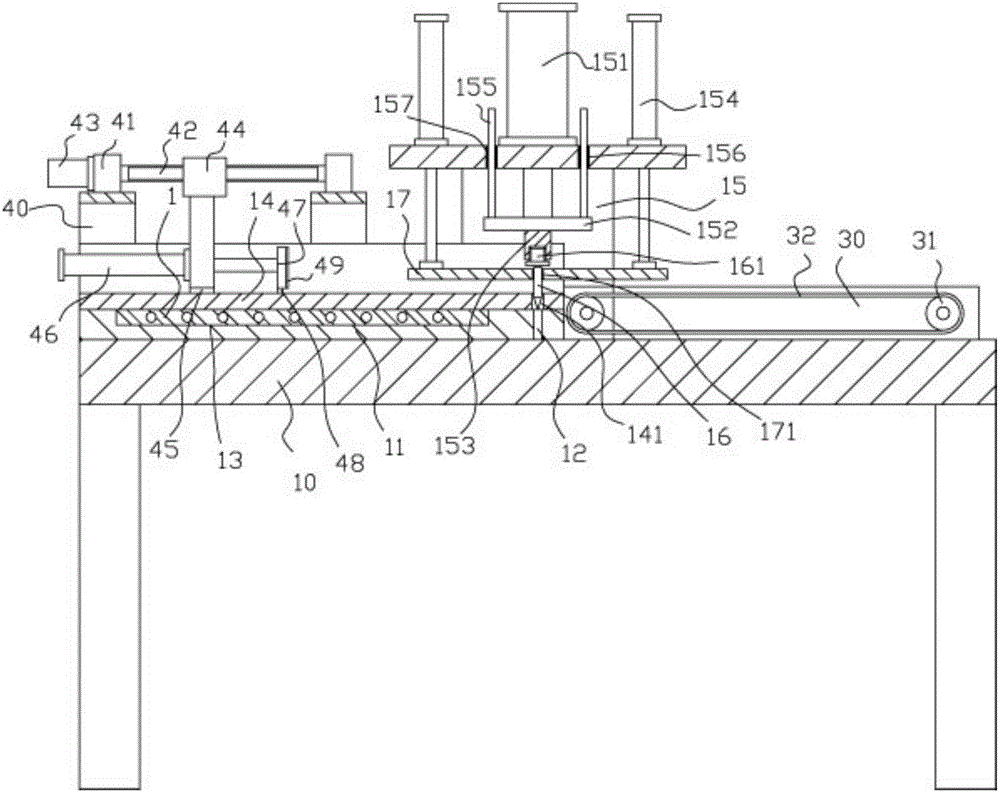

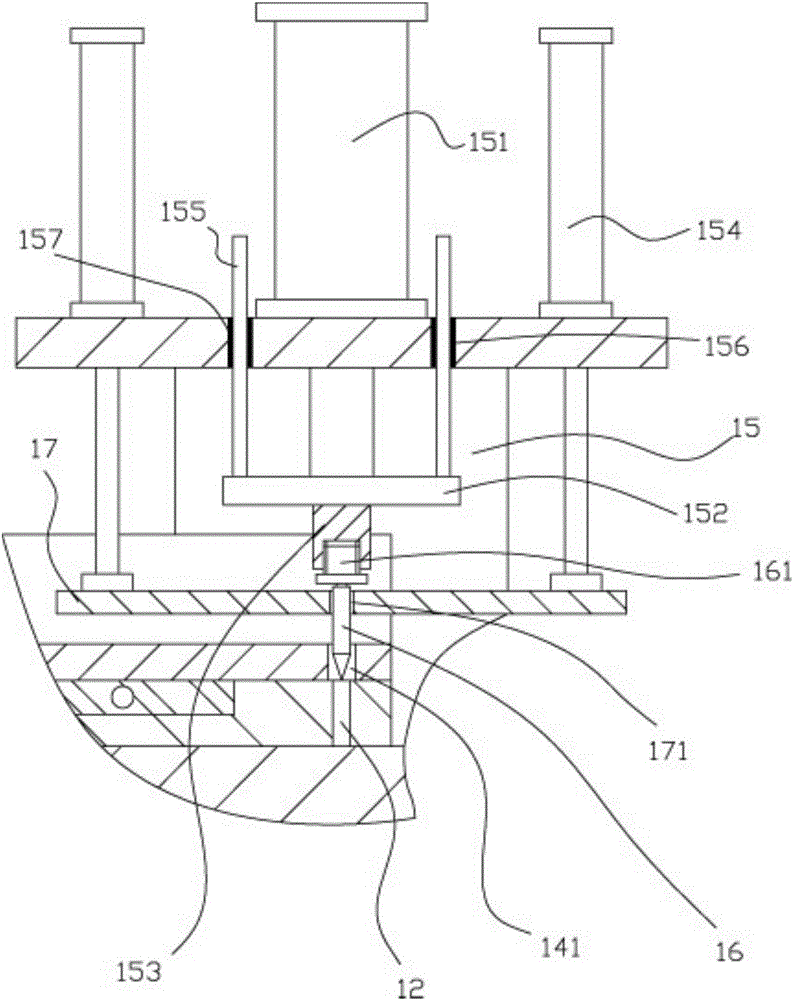

[0025] Example: see Figure 1 to Figure 4 Shown, a kind of glutinous rice cake automatic granulating device comprises conveying frame 10, and the left part top surface of the top plate of described conveying frame 10 is fixed with fixed plate 11, and the top surface right end of fixed plate 11 has cutting through groove 12, fixed The top surface of the plate 11 has a placement groove 13, the heating plate 1 is inserted and sleeved in the placement groove 13, the bottom surface of the heating plate 1 is fixed on the bottom surface of the placement groove 13, and the delivery tank body 14 is fixed on the fixed plate 11. The right end of the bottom plate of the tank body 14 has a through groove 141, and the through groove 141 is aligned up and down with the cutting through groove 12;

[0026] Side support plates 30 are fixed on both sides of the right part of the top plate of the transport frame 10, and the two ends of the two drive rollers 31 are hinged on the corresponding side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com