Grabbing and lifting adaptation robot arm

A robotic and adaptable technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve problems such as high cost, reduced service life, poor reliability, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

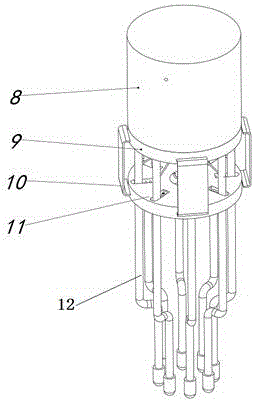

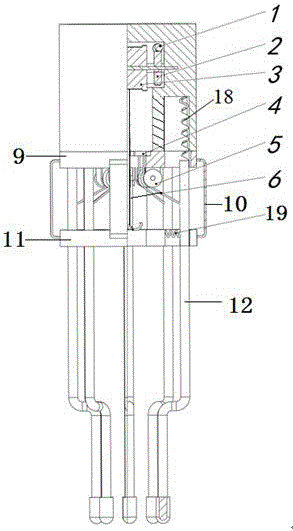

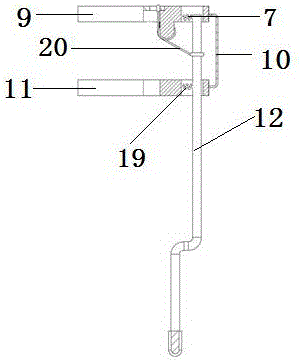

[0036] A kind of grasping adaptive robot hand described in this embodiment, such as Figures 1 to 8 As shown, it includes worm 1, turbine 2, roller 3, port cover 4, fixed pulley 5, steel rope 6, spring I7, base 8, base plate I9, fixed bracket 10, base plate II11, clamping rod 12 , hook 16, spring II 18, spring III 19, traction rope 20, turbine 2 meshes with worm 1, drum 3 is connected to turbine 2, drum 3 is provided with steel rope 6, and one end of steel rope 6 is provided with hook 16, worm 1 , the turbine 2, and the drum 3 are arranged in the base 8, the bottom of the base 8 is provided with a base plate I9, the base plate I9 has a central through hole, and a port cover 4 is provided on the central through hole, and the port cover 4 is in the shape of a wheel. Including the hub, rim and spokes, 8 strip-shaped through holes I14 are opened on the base plate I9 centered on the port cover 4 on the same circumference, and there are eight fixed pulleys 5 at the bottom of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com