Symmetrical cone rolling parts and symmetrical cone rolling devices

A cone-shaped and symmetrical technology, which is applied in the field of metal material processing, can solve the problems of inconsistent torsional deformation force of rollers, uneven linear speed of plates, and insufficient detailed and in-depth research, so as to improve processing efficiency, shorten processing time, and improve processing coverage. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

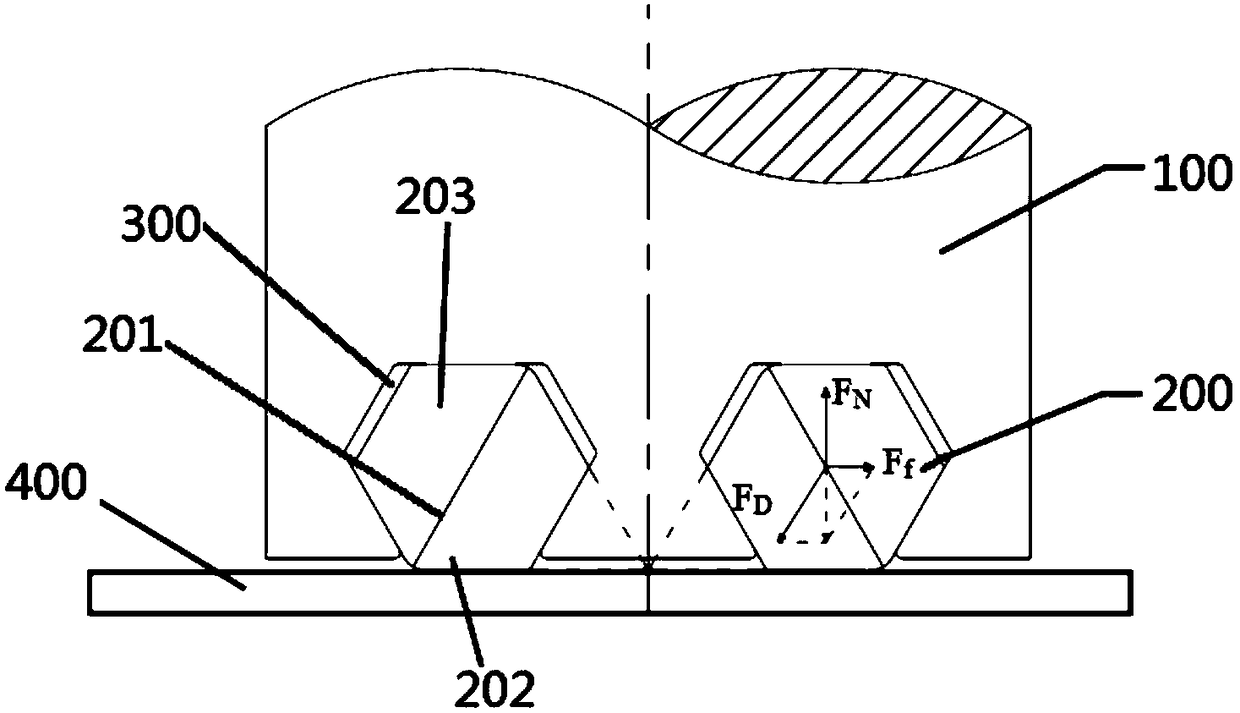

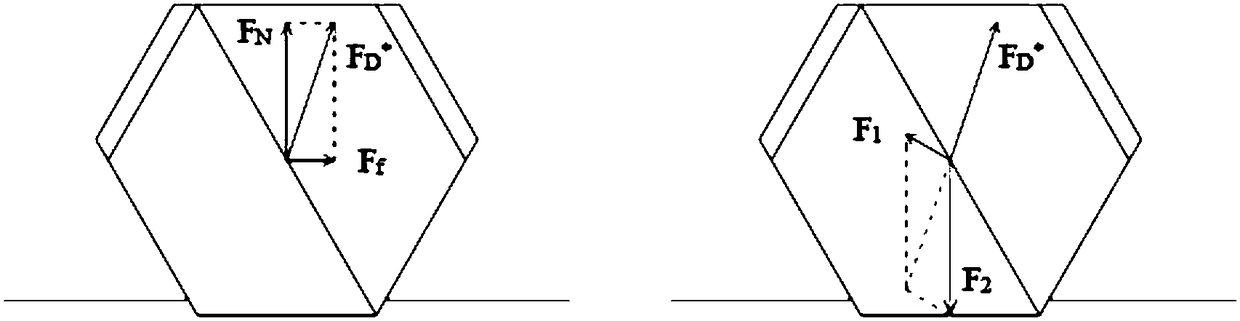

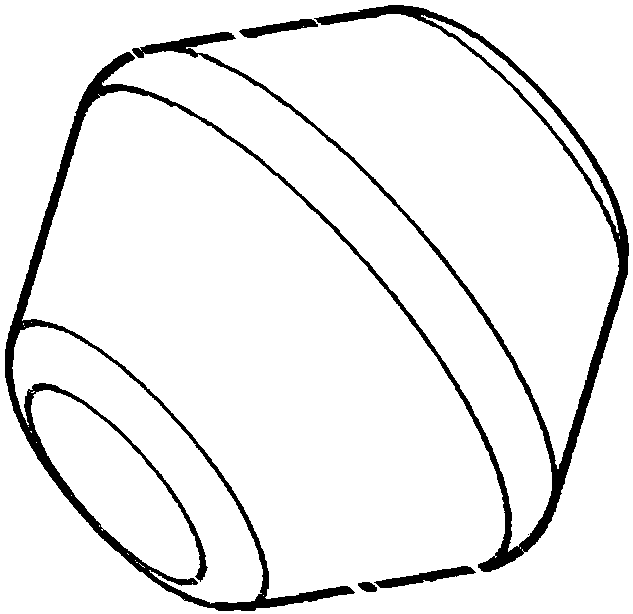

[0030] like Figure 1-4 As shown, the present symmetrical cone rolling part includes a rotary pressing body 100 and a roller indenter 200. A slot 300 is provided in the rotary pressing body, and the roller pressing head 200 is arranged in the slot of the rotary pressing body. The sub-indenter is integrally formed, and its appearance is composed of two truncated conical rollers of the same size on the bottom surface 201. The rotating surface close to the axis of the rotary pressing body is the working surface 202, and the other surface is the supporting surface 203. There are two sub-indenters, the axes of the two roller indenters and the axis of the rotating pressing body are in the same plane, and in this plane, the axes of the two roller pressing heads are aligned with the axis of the rotating pressing body. The axis line is axisymmetrically arranged. The busbar at the bottom of the working surface of the two roller indenters nested in the rotary press body is located outsid...

Embodiment 2

[0033] like Figure 5-6 As shown, the symmetrical cone rolling device includes a rotary pressing body 100, a roller indenter, a rotating pressing body driving device, a bed body, and a bed body driving device. In the embedded groove of the rotary pressing body, the roller press head is integrally formed. Its appearance is two truncated conical rollers of the same size assembled on the bottom surface, and the turning surface close to the axis of the rotating pressing body is the working surface. , the other side is the support surface, there are two roller indenters, the axes of the two roller indenters and the axis of the rotating pressing body are in the same plane, and in this plane, the two roller indenters The axis line of the rotary press body is arranged symmetrically with the axis line of the rotary press body. The busbar at the bottom of the working surface of the two roller indenters nested in the rotary press body is located outside the rotary press body and is in a ...

Embodiment 3

[0041] like Figure 7-11 As shown, the present symmetrical cone rolling part includes a rotating pressing body 100 and a roller indenter 200. The rotating pressing body includes a cage 15, a supporting shaft 16, a shaft sleeve 17, a shaft pin 18, and a connecting block 19. , rolling knife body 20, spring 21, reaming hole bolts 22,28, end straight connector 23; the support shaft 16 is cylindrical, and the middle part of the support shaft protrudes to form two bosses 161, wherein the boss below It fits with the cage 15, the upper boss is in contact with the spring 21, the cage 15 and the support shaft 16 are fixed by the shaft pin 18, the shaft sleeve 17 is set outside the support shaft 16, and the support shaft 16 can be connected by the spring 21 Apply pressure, the connecting block 19 is set above the support shaft 16, the rolling knife body 20 is set above the shaft sleeve 17, and the rolling knife body 20 and the shaft sleeve 17 are fixed by reaming hole bolts 28, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com