Improved adjustable metal plate bending device

A technology of sheet metal and bending devices, applied in metal processing equipment, other manufacturing equipment/tools, forming tools, etc., can solve the problems of time-consuming, labor-intensive, poor bending quality, etc., to reduce labor intensity, fast bending speed, Bending flat and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

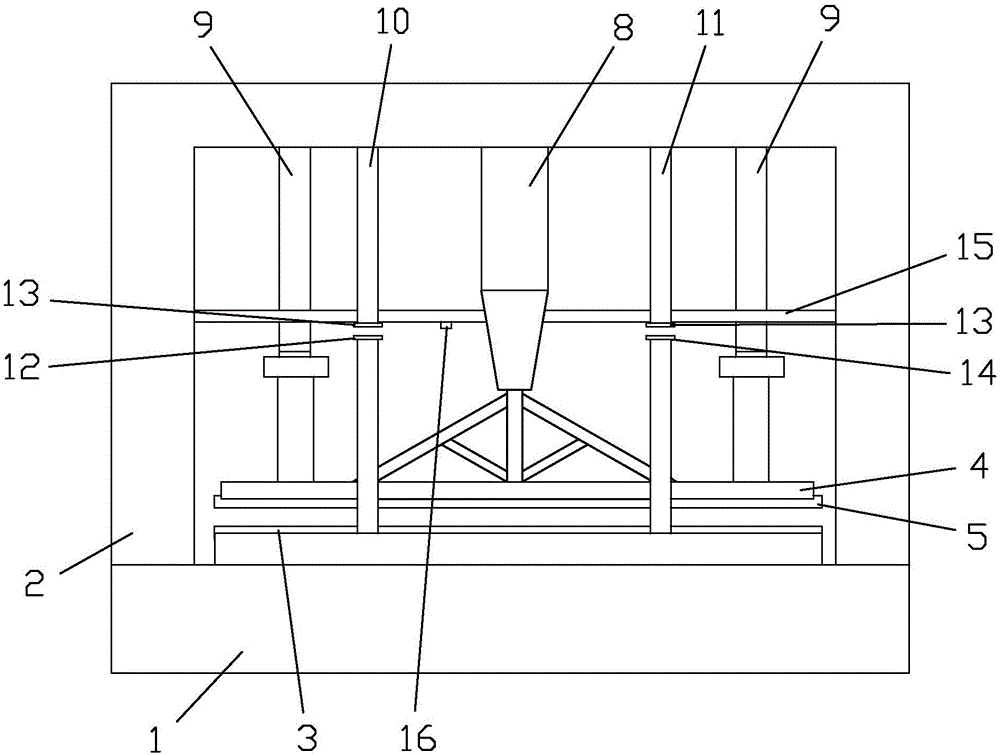

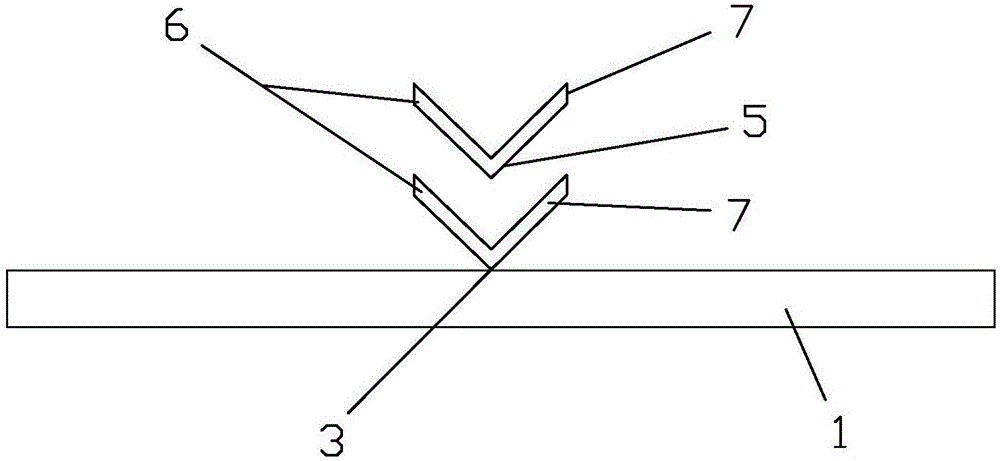

[0030] Such as figure 1 , 2 As shown, an improved adjustable sheet metal bending device according to the present invention includes a frame 1, a frame 2 is provided above the frame 1, a bending groove 3 is provided on the top of the frame 1, and the frame 2 Corresponding to the bending groove 3 is provided with a hydraulic device, the lower part of the hydraulic device is provided with a pressing frame 4, the bottom of the pressing frame 4 is provided with a pressing protrusion 5 matching the bending groove 3, and corresponding to the bending groove 3 is provided The water spray cooling device prevents the metal plate from overheating and affecting the subsequent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com