A vibration buffer device for rotary vibrating screen

A technology of buffer device and rotary vibrating screen, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of reducing the service life of multiple parts of rotary vibrating screen, long resonance shaking time of the body, and increasing screening production cost, etc. To achieve the effect of shortening the generation time, shortening the gradual decrease of the motor speed and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

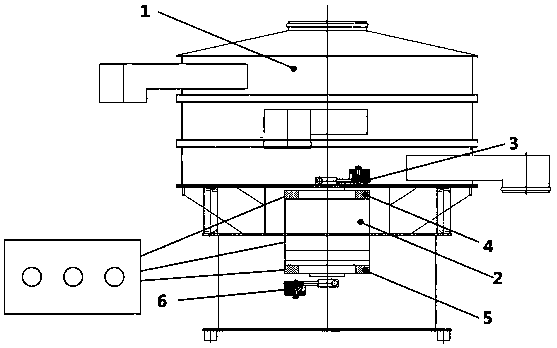

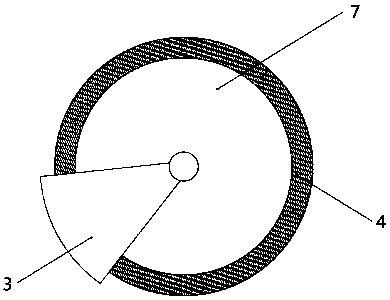

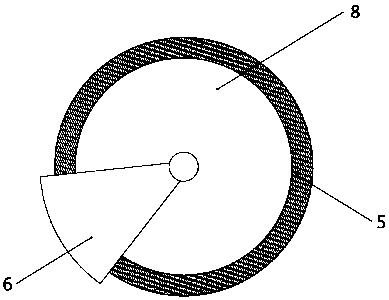

[0012] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. A resonant buffer device for a rotary vibrating screen, comprising a screen machine main body 1, a protective cover is provided on the upper part of the screen machine main body 1, a feeding port is provided on the protective cover, a screen frame is provided inside the screen machine main body 1, and a screen frame is provided inside the screen machine main body 1. The side wall of the main body 1 is provided with a discharge port, and the bottom frame of the screen machine at the bottom of the main body 1 of the sieve machine is provided with a vibration motor 2 fixedly connected with the screen frame. The position is fixed and the upper ring electromagnet 4 is installed, and the lower end cover 8 outer edge of the vibration motor 2 is adjacent to the position of the lower throwing block 6. The lower ring electromagnet 5 is installed, the vibration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com