Ventilation and heat exchange system for granary

A heat exchange system and granary technology, applied in the field of heat exchange, can solve the problems of high cost, inability to detect and monitor grain storage in the granary, and occupy a large area, and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

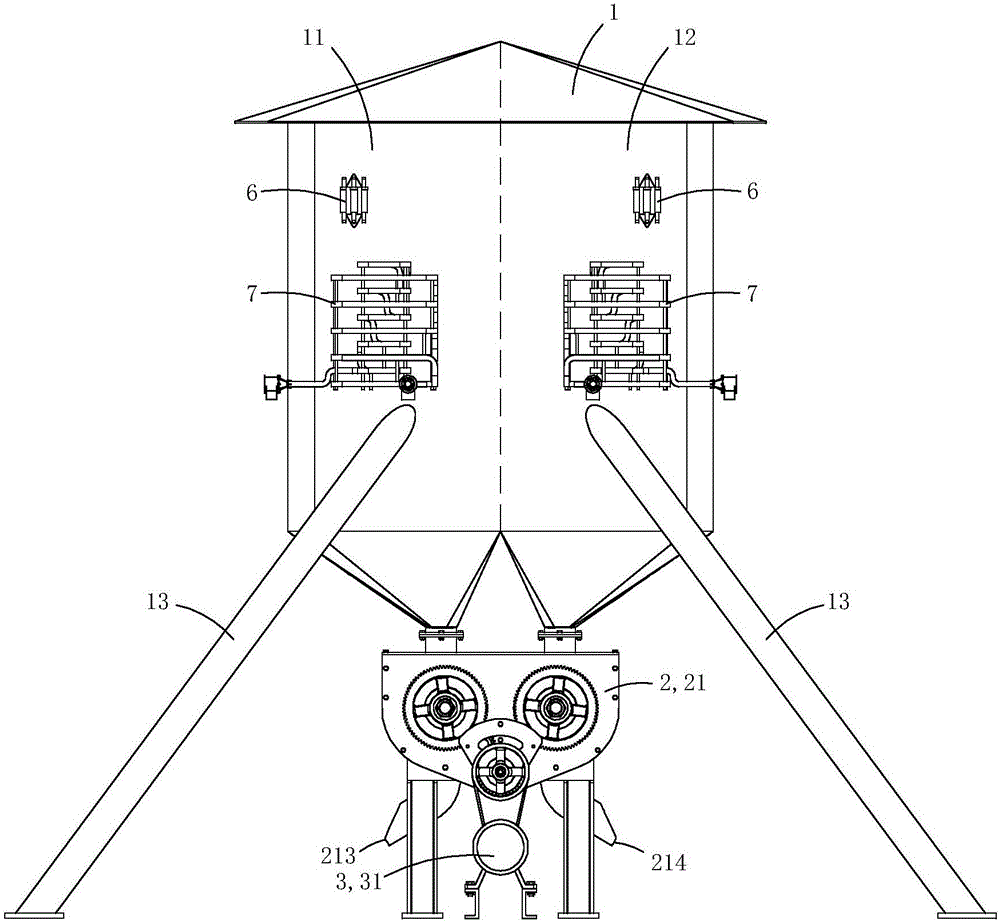

[0028] figure 1 and figure 2 One specific embodiment of the invention is shown.

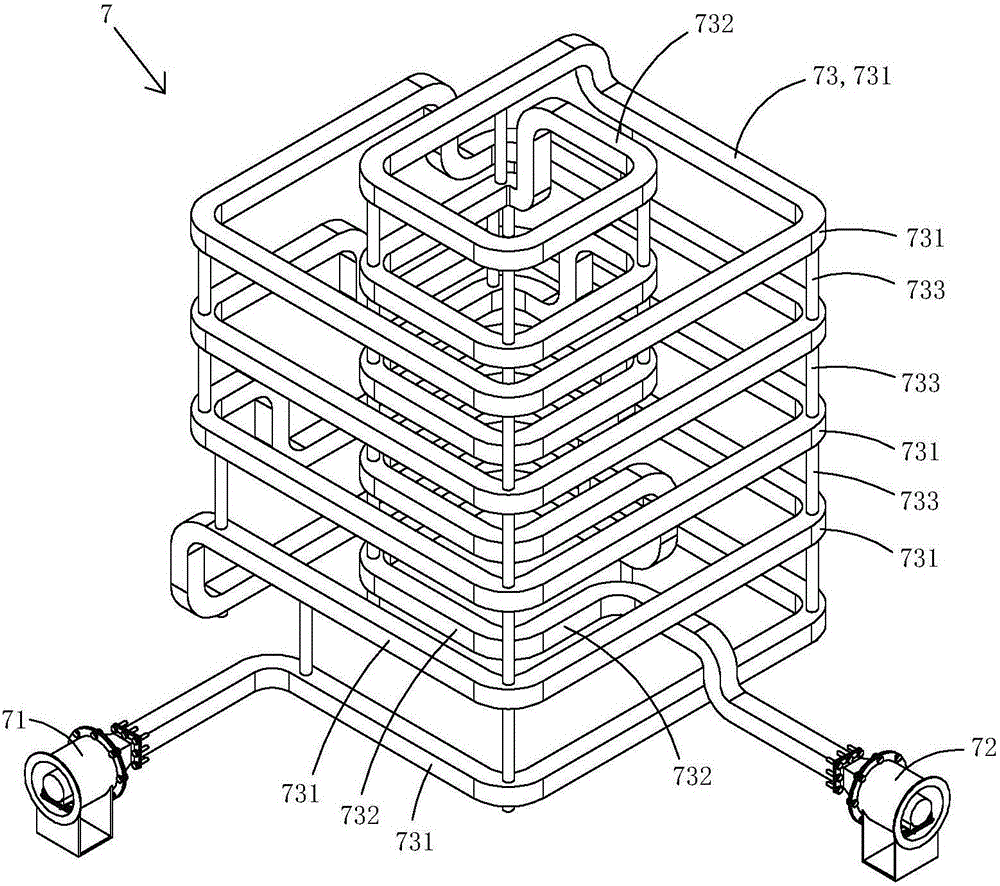

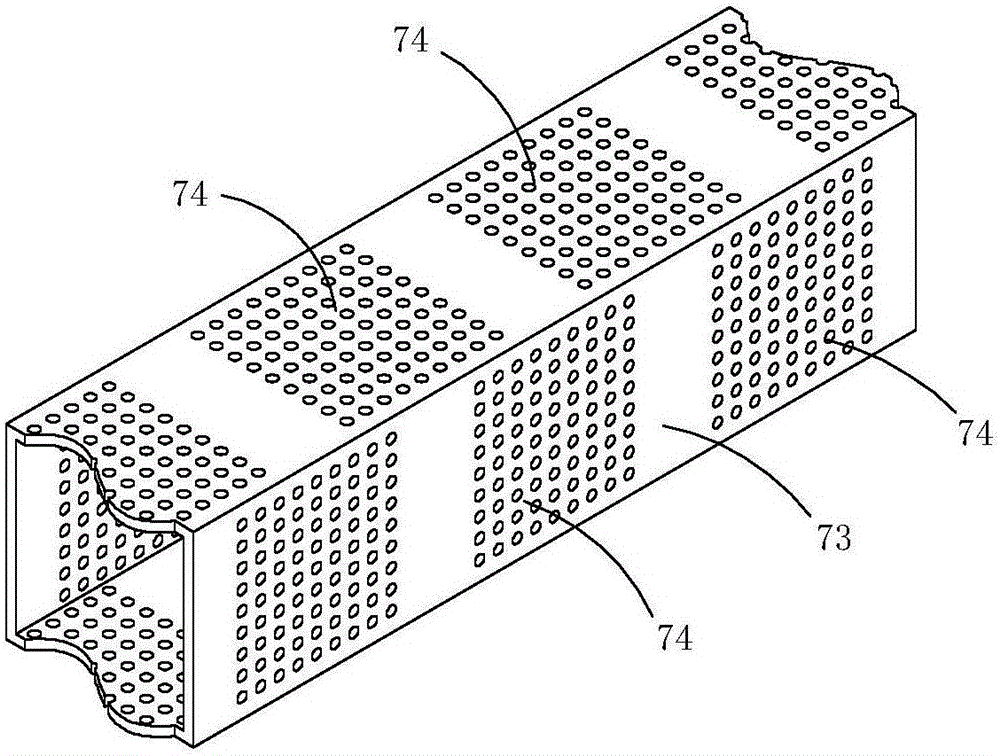

[0029] This embodiment is a kind of ventilation and heat exchange system for granary, see figure 1 and figure 2 As shown, the ventilation heat exchange system 7 includes an exhaust fan 71, a suction fan 72 and a ventilation duct 73; the ventilation duct includes an outer ring air pipe 731, an inner ring air pipe 732 and a support rod 733 for connecting and supporting the pipe body; The circle air duct is located in the space enclosed by the outer circle air duct. One end of the ventilation duct is connected to the exhaust fan, and the other end is connected to the suction fan; through this air supply method of suction and suction, the wind force of the entire ventilation duct can be circulated more quickly, thereby improving the heat exchange efficiency.

[0030] In this embodiment, the top of the inner air duct is connected to the top of the outer air duct, the opening at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com