Laser light source module group and light source system

A technology of laser light source and module, which is applied in the field of laser light source to achieve the effect of high sensitivity adjustment and no delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

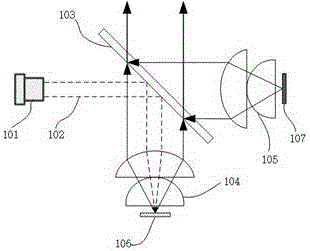

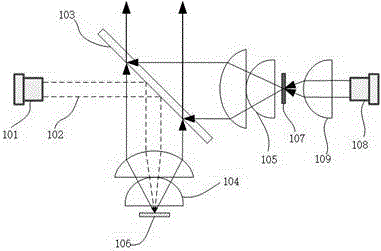

[0010] figure 1 It is a structural schematic diagram of the first embodiment of the laser light source module of the present invention, such as figure 1 As shown, the laser light source module includes a laser diode 101 , a filter 103 , a first focusing lens group 104 , a second focusing lens group 105 , a fluorescent layer 106 , and an LED 107 . The laser diode 101, the first focusing lens group 104, and the fluorescent layer 106 are arranged on one side of the optical filter 103, the second focusing lens group 105, and the LED 107 are arranged on the other side of the optical filter 103, and the first emitted from the laser diode 101 A light beam 102 is reflected by the optical filter 103 and enters the reflection light path, and the first focusing lens group 104 of the reflection light path focuses the first light beam 102 onto the fluorescent layer 106 . The fluorescent layer 106 is arranged on a reflective substrate. The fluorescent layer 106 can absorb the laser light e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com