Electrothermal grouping regeneration device of metal particle trap of diesel car

A technology of metal particles and regeneration device, applied in the direction of muffler device, exhaust device, electric control of exhaust treatment device, etc., can solve the problems of high process requirements, high fuel consumption, difficult particle combustion, etc., and achieve a simple regeneration control system , energy saving and emission reduction effect, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

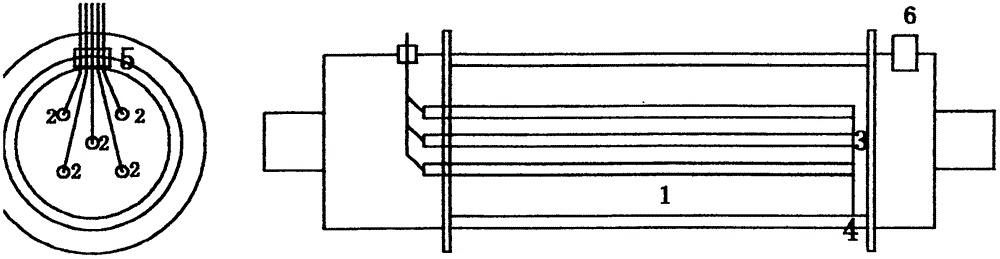

[0009] As shown in Figure 1, a grouped electrothermal regeneration device for a diesel automobile metal particle trap according to an embodiment of the present invention includes five pre-installed groups balanced in the metal filter 1 of the diesel automobile metal particle trap. A linear electric heater 2 made of multiple round core wires. Use stainless steel wire as a wire to weld one end of each group of electric heaters in parallel to form a common end 3. The other end of the stainless steel wire leads to the metal filter and welds the shell of the trap. 4. The housing of the trap is used as the negative electrode of the power supply, and the other end of the electric heater group. Each group of electric heaters is welded with a stainless steel wire to lead out the filter. Each stainless steel wire is fixed to the gas inlet assembly shell of the trap. The ceramic body terminal row posts 5 are connected in order, and one end of the terminal post extends out of the shell, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com