Precast assembled bridge pier manufactured from U-shaped reinforcing steel bars, and connection process of precast assembled bridge pier

A prefabricated, U-shaped technology, used in the erection/assembly of bridges, bridges, bridge parts, etc., can solve problems such as steel bar pull-out damage, people's disaster economy, mechanical sleeve steel bar brittleness, etc., to avoid steel bar pull-out damage , speed up the construction speed, enhance the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

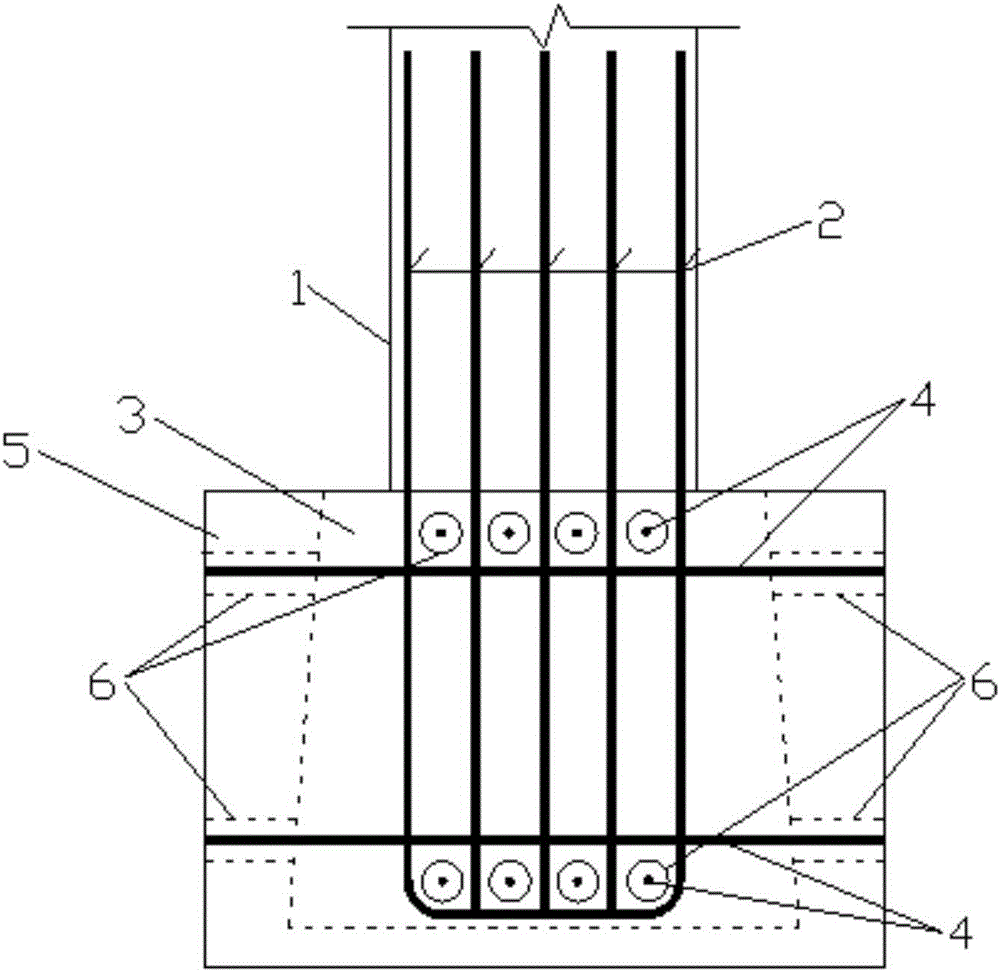

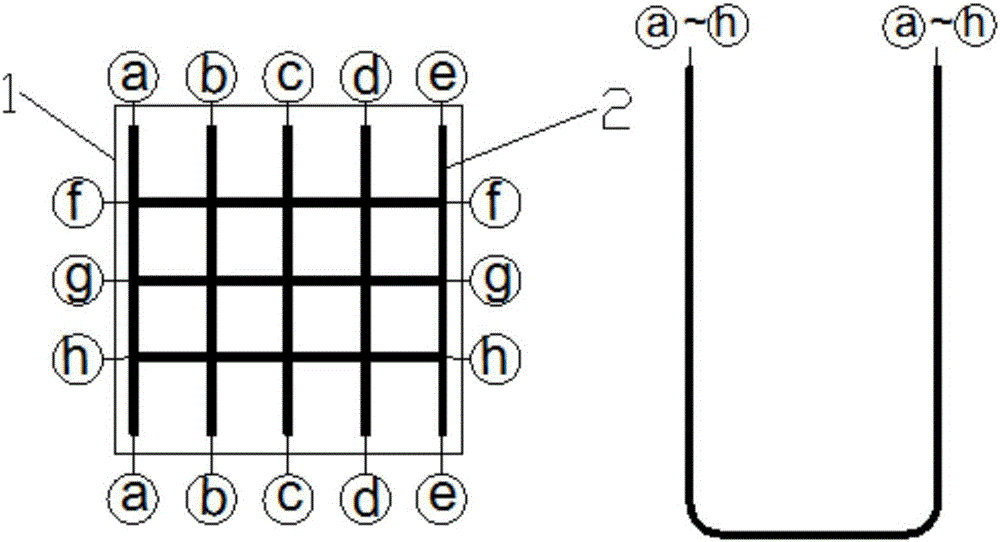

[0047] In order to better understand the technical points of the present invention, the present invention takes a rectangular pier column of 0.45×0.45m as an example, assuming that there are 5 steel bars arranged on each side, and a total of 16 bars are seen from the cross-section of the U-shaped steel bar at the bottom of the pier body Longitudinal reinforcement is actually composed of 8 U-shaped steel bars, and those with the same letter are the same U-shaped steel bar, such as All are U-shaped bars.

[0048] like Figure 9 Shown, a kind of connection technology of the prefabricated assembled pier that adopts U-shaped steel bar to make of the present invention comprises the following steps:

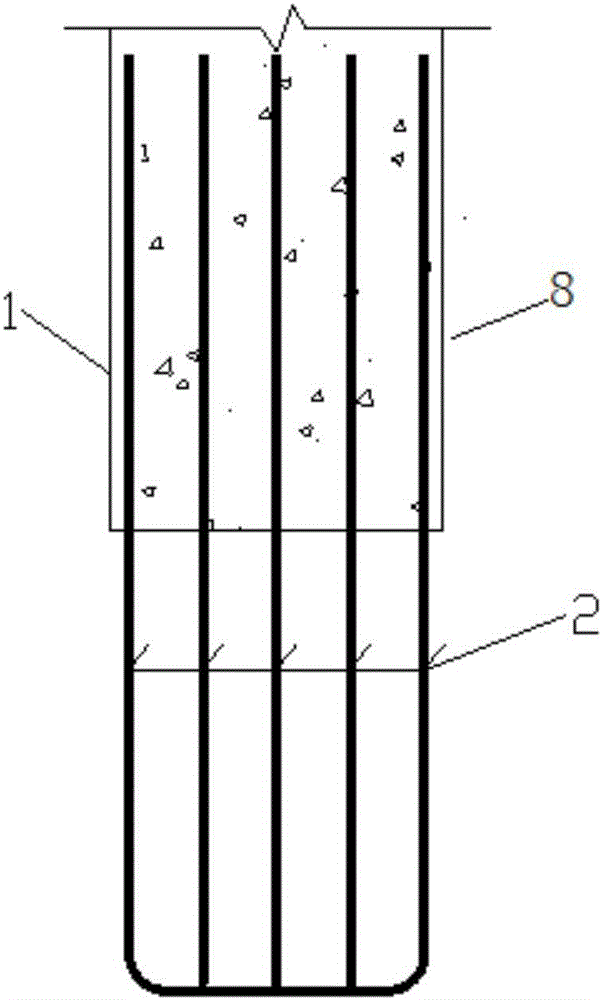

[0049] (1) Prefabricated pier stage

[0050] Bind the U-shaped reinforcement cage 9 on the platform, and pour the pier column 1 at one end of the U-shaped reinforcement cage 9, such as through processes such as vertical formwork, pouring concrete, maintenance, and demoulding, to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com