A kind of negative ion powder dispersion liquid for preparing negative ion viscose fiber and preparation method thereof

A technology of negative ion powder and viscose fiber, applied in the direction of fiber chemical characteristics, single-component cellulose rayon, rayon manufacturing, etc., can solve problems such as deterioration of spinning conditions, difficulty in coagulation bath filtration, and decrease in transparency of coagulation bath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

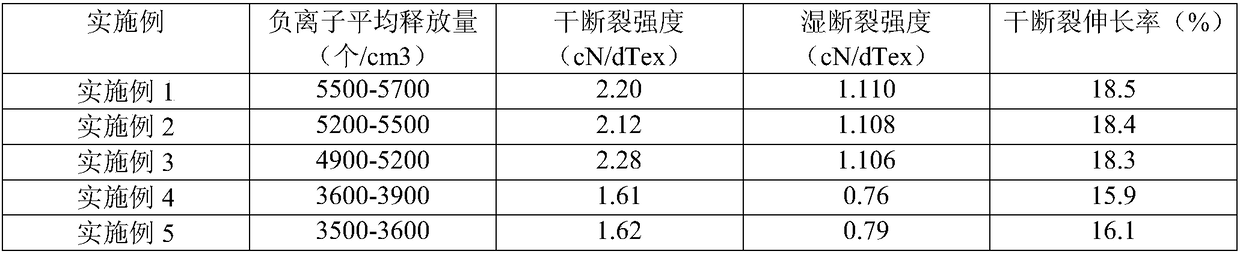

Examples

preparation example Construction

[0052] The second aspect of the present invention aims to provide a kind of preparation method for the negative ion powder dispersion liquid that is used to prepare negative ion viscose fiber, comprises the following steps:

[0053] a) preparing an aqueous dispersant solution, then adding an electrolyte to the aqueous dispersant solution, and mixing to obtain an aqueous dispersant solution;

[0054] b) Add the negative ion powder to the aqueous dispersant solution prepared in step b), stir evenly, and grind until the medium particle size D50≤0.3 μm.

[0055] In some embodiments, the anion powder added in step b) is obtained by soaking in alkaline solution in advance and then filtering.

[0056] In the method of the present invention, the negative ion powder is soaked in an alkaline solution to weaken the intercrystalline structure of the negative ion powder, greatly increase the wet grinding effect, and shorten the grinding time by 3 to 4 times.

[0057] In some embodiments, ...

specific Embodiment approach

[0079] In order to enable those skilled in the art to better understand the technical solutions of the present invention, some non-limiting examples are further disclosed below to further describe the present invention in detail.

[0080] The reagents used in the present invention can be purchased from the market or can be prepared by the methods described in the present invention.

Embodiment 1

[0082] Negative ion dispersion and its preparation:

[0083] components

Weight (g)

tourmaline powder

100

flat plus

20

sodium sulfate decahydrate

150

[0084] Weigh 100g of tourmaline powder in a 1L beaker, add 500g of 30% sodium hydroxide, soak for 24h, suction and filter through a Buchner funnel, filter dry, and weigh 139g.

[0085] Preparation of dispersant aqueous solution: weigh 20g of Pingping, 150g of sodium sulfate decahydrate, mix and add to a 1-liter beaker, slowly add deionized water, add while stirring, until the solid mixture is completely dissolved, the dispersant weighs 455g, measure The specific gravity is 1.46g / cm 3 .

[0086] Add 139g of filter cake to 455g of dispersant aqueous solution, stir evenly, add 500g of zirconia beads with a diameter of 2.0 to 2.8mm in an experimental vertical grinder for grinding, and use a laser particle size analyzer to detect during the process. When the diameter D50 is ground to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com