A simple food mixing mechanism

A mixing mechanism and food technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of materials and droplets splashing out, affecting the environment, etc., and achieve good effect and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

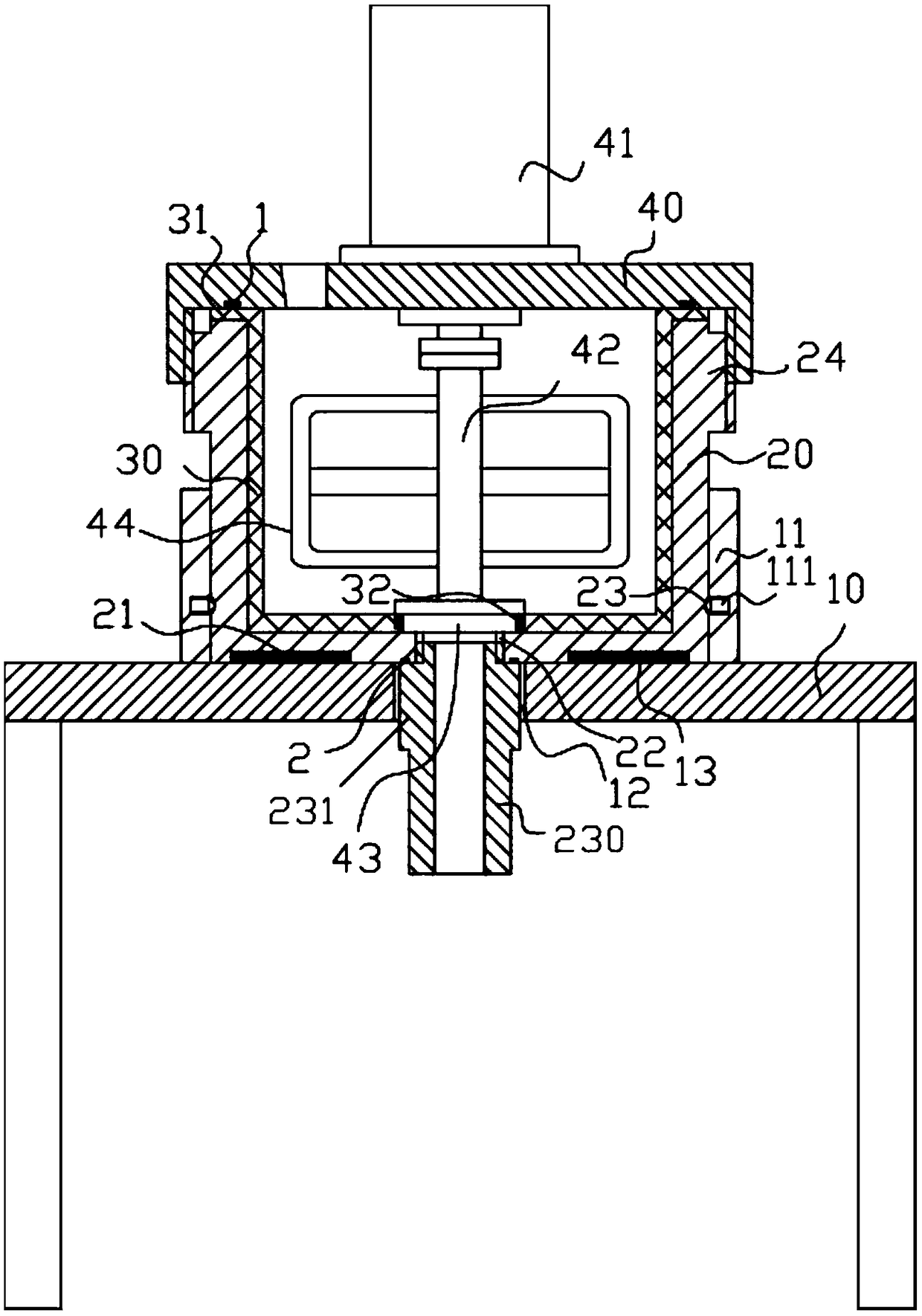

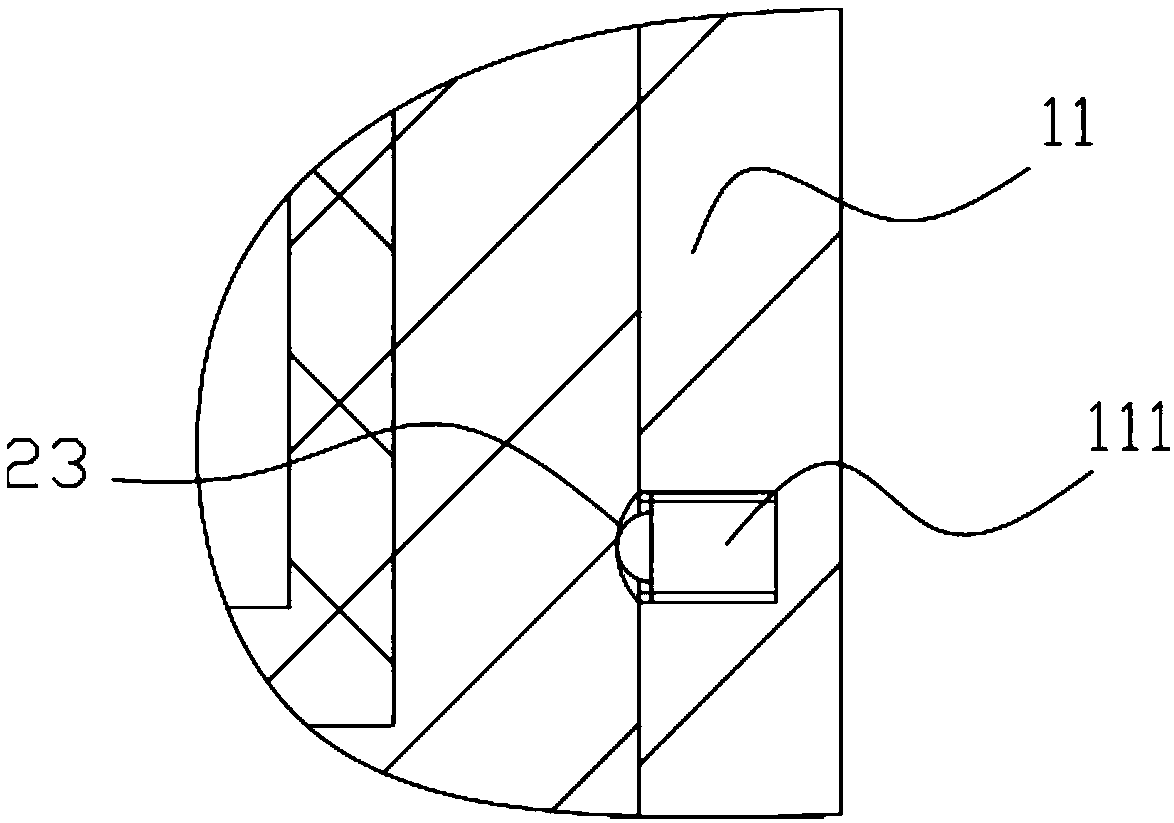

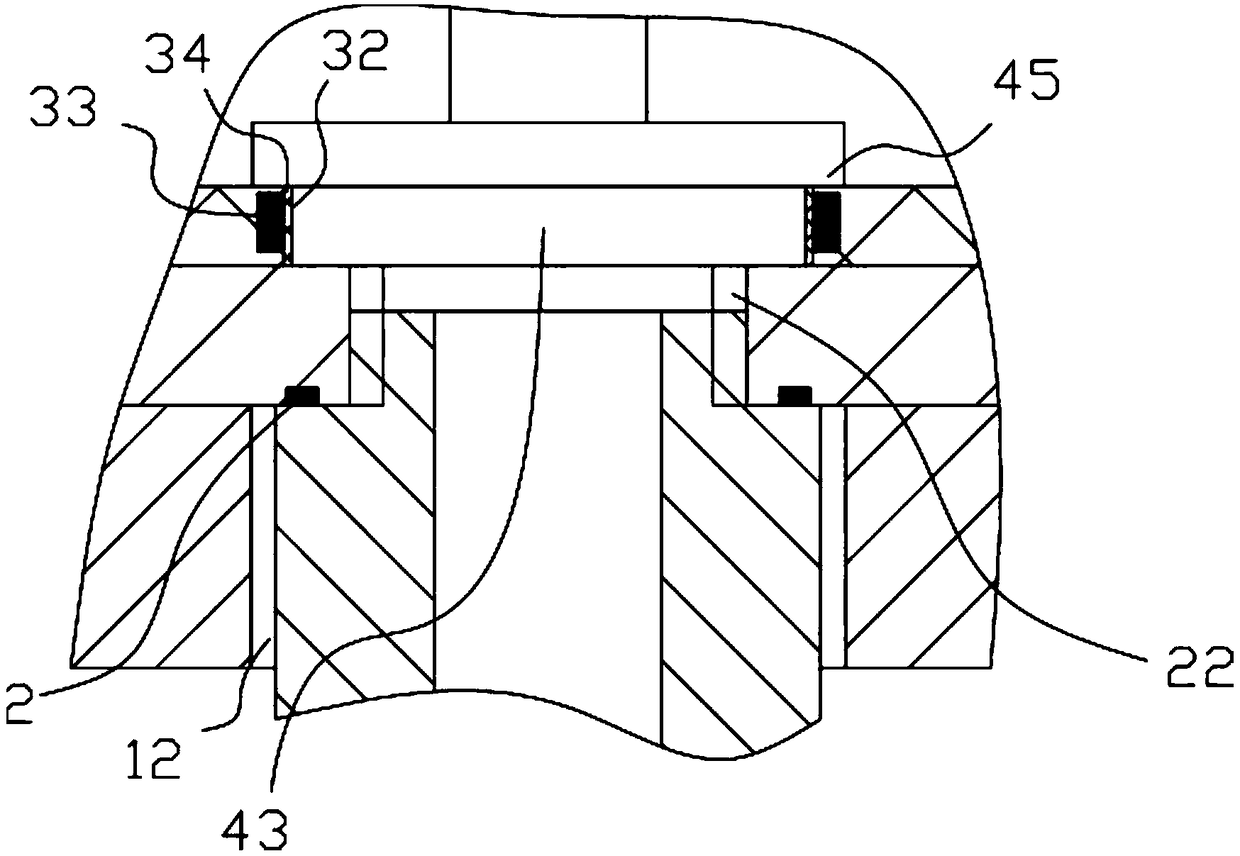

[0017] Example: see Figure 1 to Figure 3 Shown, a kind of simple and easy food stirring mechanism comprises frame 10, and the top plate of described frame 10 is fixed with annular cover 11, and the middle part of the top plate of described frame 10 has vertical jack 12, and the top plate of frame 10 The top surface of the main barrel body 20 is fixed with a plurality of bar-shaped permanent magnet blocks 13, the main barrel body 20 is inserted and sleeved in the annular sleeve 11, the bottom surface of the main barrel body 20 is pressed against the top surface of the top plate of the frame 10, and the main barrel body 20 The bottom surface has a plurality of limiting grooves 21, the bar-shaped permanent magnet block 13 is nested in the limiting groove 21, and the bar-shaped permanent magnet block 13 is adsorbed on the main barrel body 20;

[0018] The bottom plate of the main barrel body 20 has a screw through hole 22, the upper end of the discharge pipe 230 is screwed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com