Preparation method of ancient-process brown sugar

A technology for brown sugar and syrup, applied in confectionery, confectionery industry, functions of food ingredients, etc., can solve the problems of single taste and function of brown sugar, low production efficiency and high moisture content, and achieve rich taste, high production efficiency, and high moisture content. low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

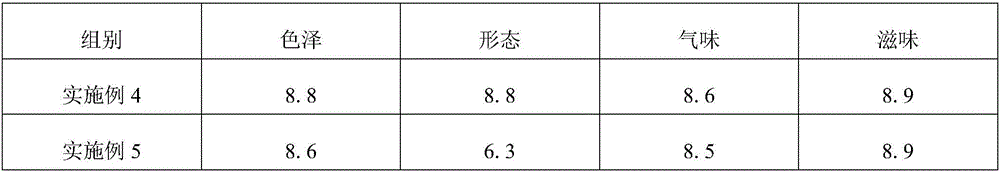

Examples

Embodiment 1

[0035] The preparation of embodiment 1, ginger powder

[0036] Take fresh ginger, peel it, clean it, slice it, freeze it at -6°C for 2 hours, put the above-mentioned pre-frozen ginger slices into a vacuum freeze dryer for drying, the drying temperature is -53°C, and the drying time is 24 hours , vacuum tightness is 0.1kpa, pulverizes, crosses 50 mesh sieves, gets ginger powder.

Embodiment 2

[0037] Embodiment 2, the preparation of tangerine peel powder

[0038] Take dried orange peel and put it into a vacuum freeze dryer for drying. The drying temperature is -55° C., the drying time is 24 hours, the vacuum degree is 0.1 kpa, pulverized, and passed through a 50-mesh sieve to obtain orange peel powder.

Embodiment 3

[0039] Embodiment 3, the preparation of Radix Glycyrrhizae extract

[0040] Take licorice, wash it, add 5 times the amount of licorice in purified water and decoct twice, combine the decoction liquid, filter, concentrate, dry and pulverize to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com